Chinese chestnut sorting system

A sorting system and chestnut technology, applied in sorting and other directions, can solve problems such as inability to grade the appearance, chestnut kernels do not have rolling, damage to chestnut kernels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

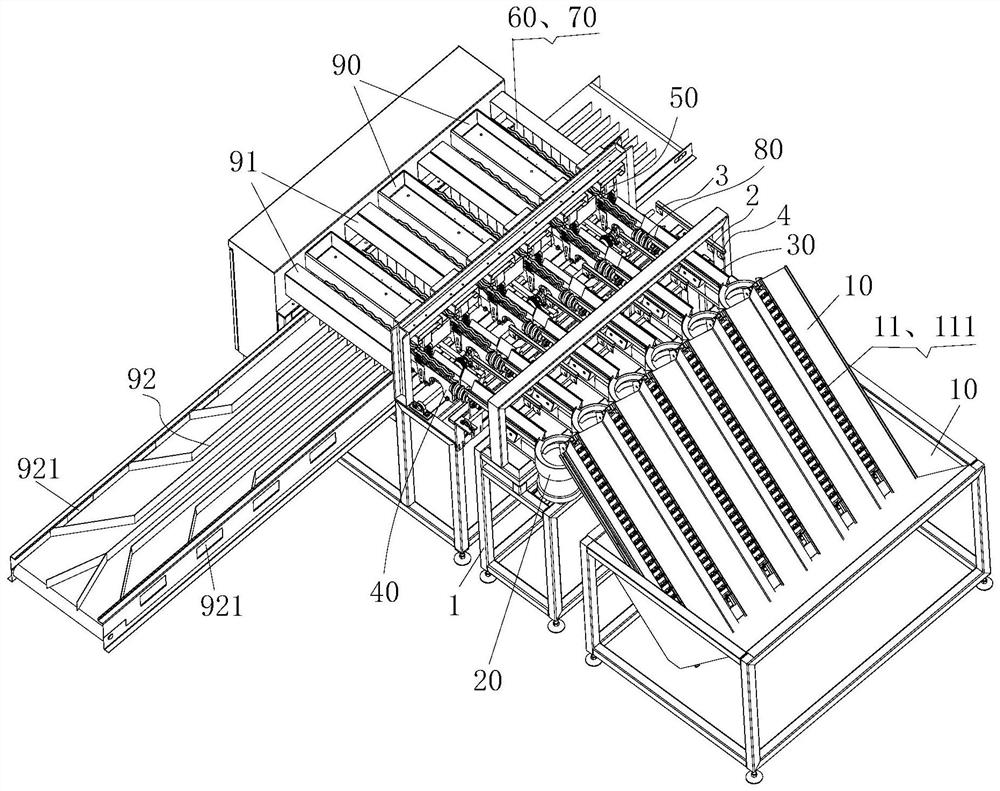

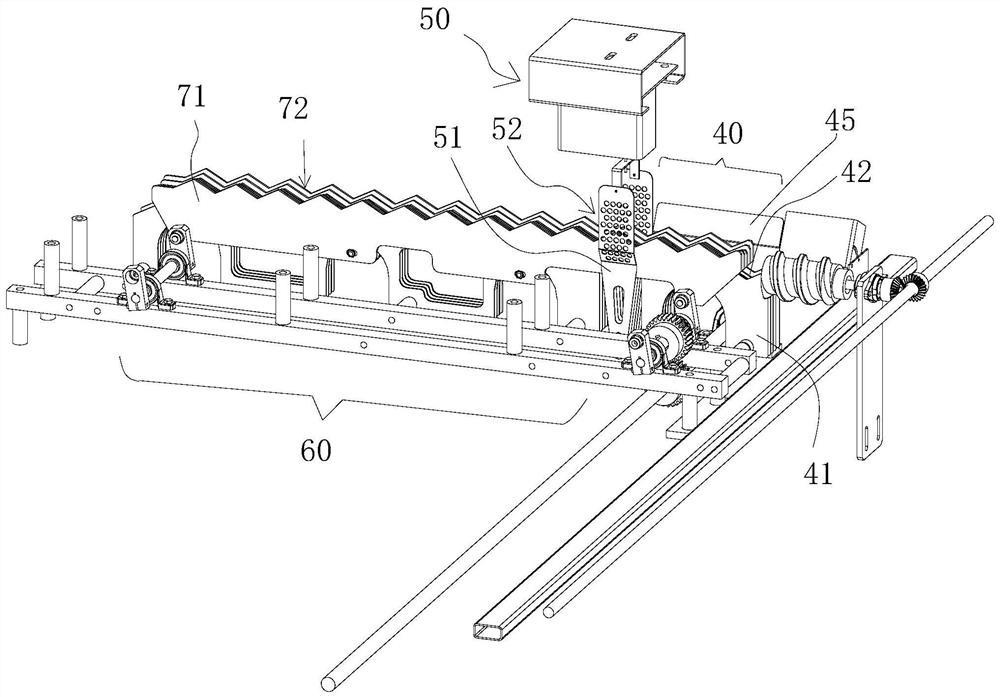

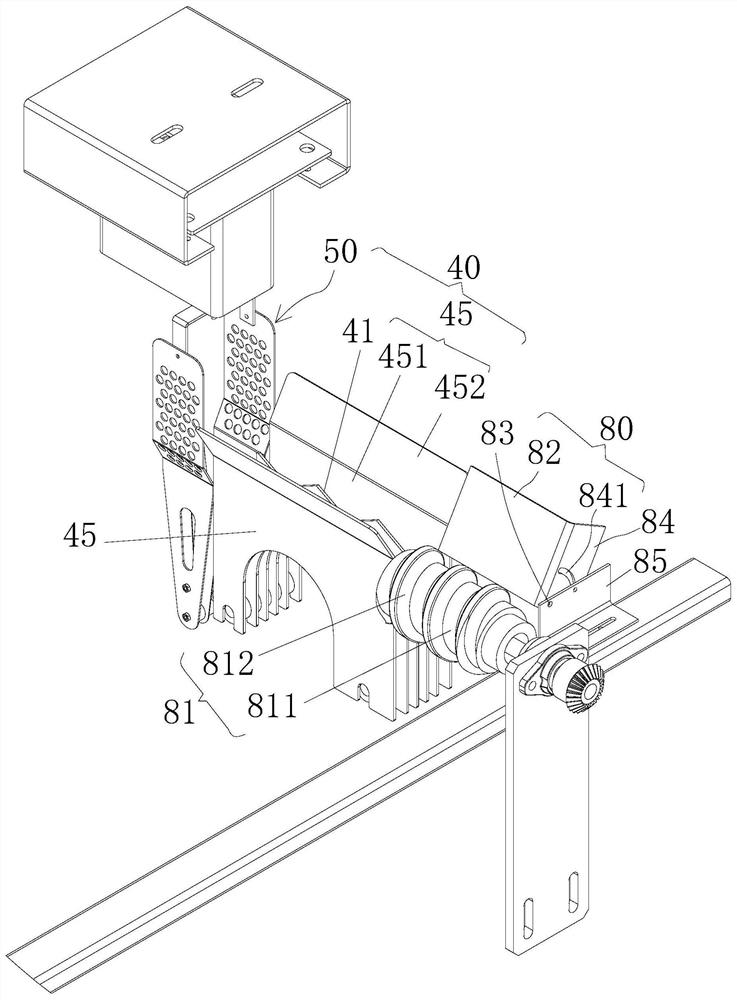

[0017] A chestnut sorting system, the hopper 10, the upstream and downstream of the vibrating feeder trough 30 are arranged sequentially, the discharge end of the vibrating feeder chute 30 is connected with an upstream fixed bracket 40, the upstream fixed bracket 40 and the downstream fixed bracket There is a weighing bracket 50 between the racks 60, and there is a transfer rack 70 on the arrangement path of the upstream fixed rack 40, the weighing rack 50 and the downstream fixed rack 60;

[0018] There is a sensor on rack 1 to send the signal of whether there is material in the corresponding station to the processing control unit, and the processing control unit outputs a driving signal to start or stop the corresponding upstream or downstream equipment to run;

[0019] The upstream fixed rack 40, the weighing rack 50, the downstream fixed rack 60 and the transfer rack 70 are all composed of toothed plates whose plate surface is located in the vertical plane at intervals, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com