Steel pipe necking machine

A closing machine and steel pipe technology, which is applied in the field of water conservancy projects, can solve the problems that the closing device is bulky, cannot be easily plugged and connected, and is not convenient for mobile use on the construction site, and achieves the effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

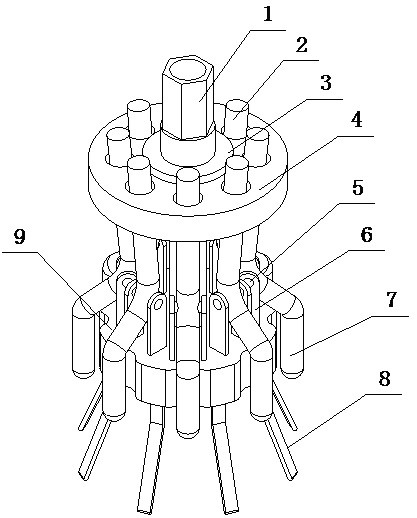

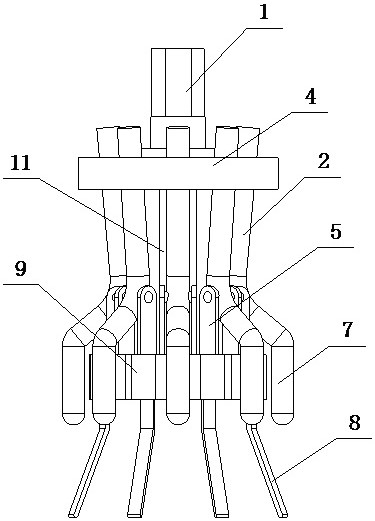

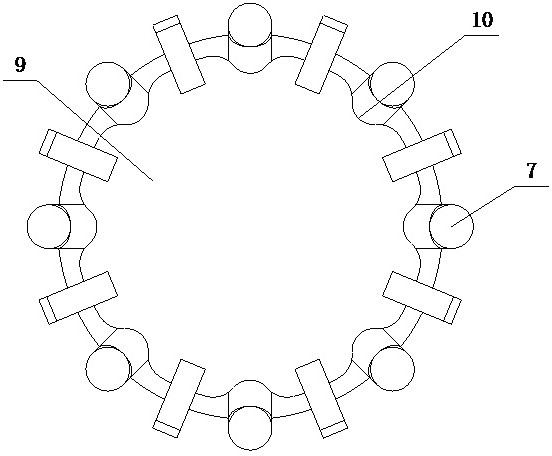

[0020] A steel pipe closing machine of the present invention is realized in the following way: a steel pipe closing machine of the present invention consists of a twisting sleeve (1), a driving rod (2), a supporting sleeve (3), a sliding support sleeve (4), and a hinged shaft ( 5), fixed ear (6), extrusion column (7), centering piece (8), profiling block (9), groove (10) and stud (11), the stud (11) One end is fixed on the profiling block (9), the other end of the stud (11) extends upwards, the sliding brace sleeve (4) is placed on the stud (11), and is close to the stud (11) On the other end, the screwing sleeve (1) is screwed and placed on the other end of the stud (11), the supporting sleeve (3) and the screwing sleeve (1) are fixedly connected, and the supporting sleeve (3) and the sliding brace The sleeves (4) fit together, and there are a plurality of round holes on the sliding block at equal angles, and a plurality of driving rods (2) are inserted into the plurality of ...

Embodiment 2

[0023] The difference between this embodiment and Embodiment 1 is: a spring (12) is sheathed on the stud (11), one end of the spring (12) is connected to the profiling block (9), and the spring ( The other end of 12) is connected with the sliding brace (4), and the sliding brace can slide; when in use, it can support the sliding brace (4) to prevent the sliding brace (4) from sliding down at the beginning to squeeze The rotation of the pressure column (7) affects the normal use of personnel.

Embodiment 3

[0025] The difference between this embodiment and Embodiment 1 is that a screw (14) is screwed on the extruding rod, the screw (14) runs through the extruding rod, and a pressing plate (13) is placed on the screw (14) When in use, personnel can adjust the extension length of the screw (14), and then adjust the extension length of the pressure plate (13), to squeeze the pipe wall, so as to adapt to the closing of stainless steel pipes with different pipe diameters, and have a wide range of applications;

[0026] The connection between the extruding column (7) and the driving rod (2) is designed as an oblique rod, so that the connection between the extruding column (7) and the driving rod (2) is stable and the driving is convenient;

[0027] The other end of the centering piece (8) first extends vertically downwards, and then extends obliquely away from the center line of the sliding brace (4), so that the centering piece (8) is elastic as a whole, and the inner pipe wall is elas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com