A kind of sealing method of powder metallurgy chromium alloy fuel cell connector

A fuel cell and powder metallurgy technology, which is used in fuel cell parts, fuel cells, electrical components, etc., can solve the problem of inability to isolate oxidizing gas and fuel gas, the conductivity of the sealing hole needs to be improved, and the airtightness of the connection cannot be guaranteed. It can achieve the effect of good application prospect, simple sealing method and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

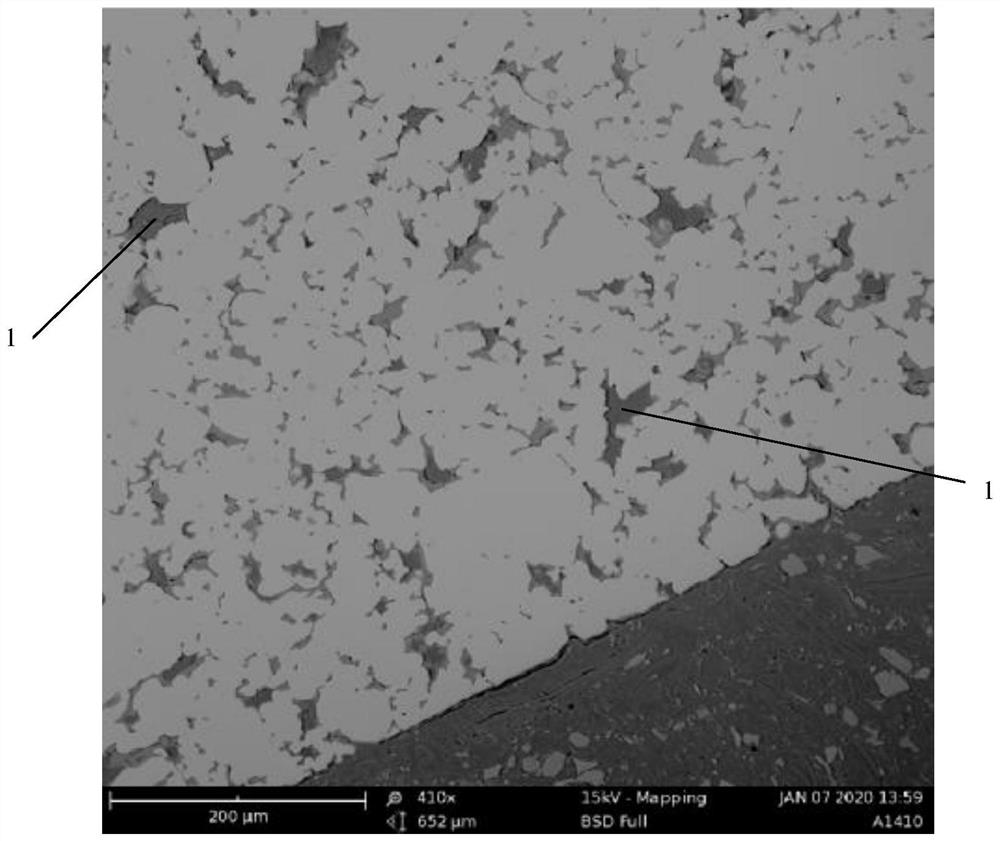

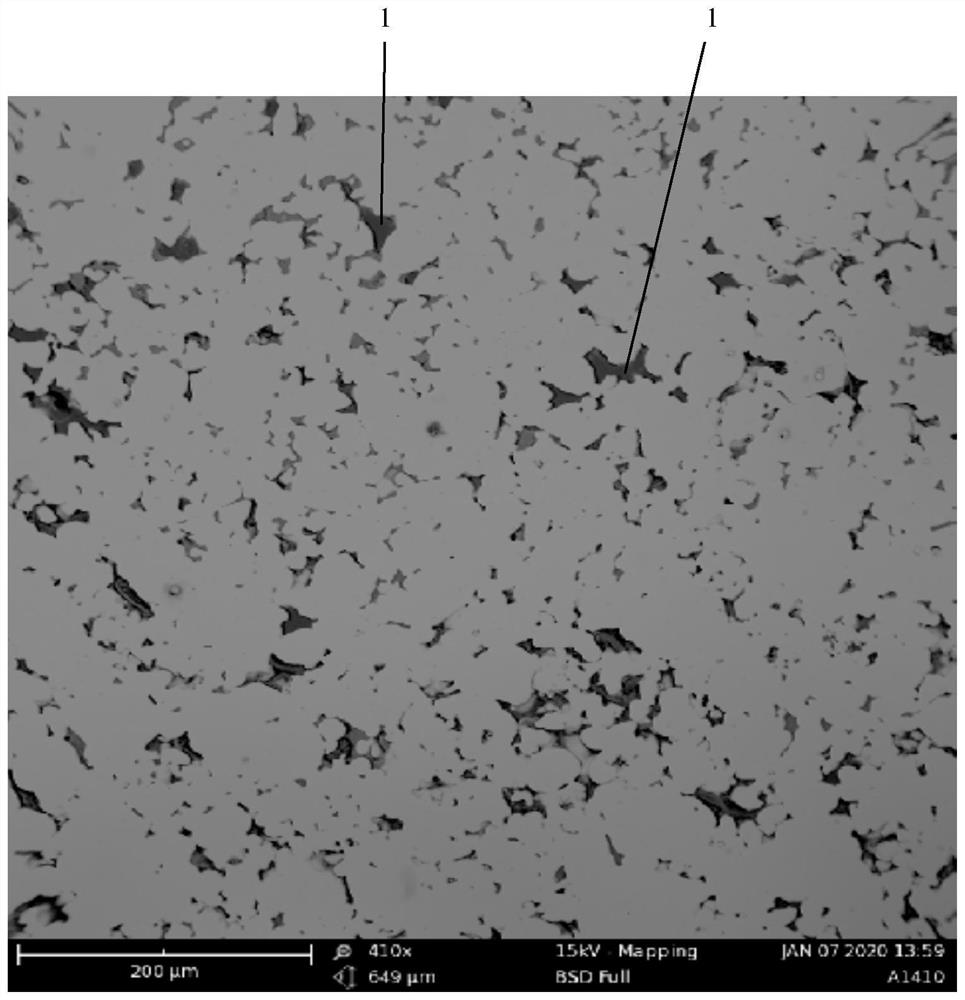

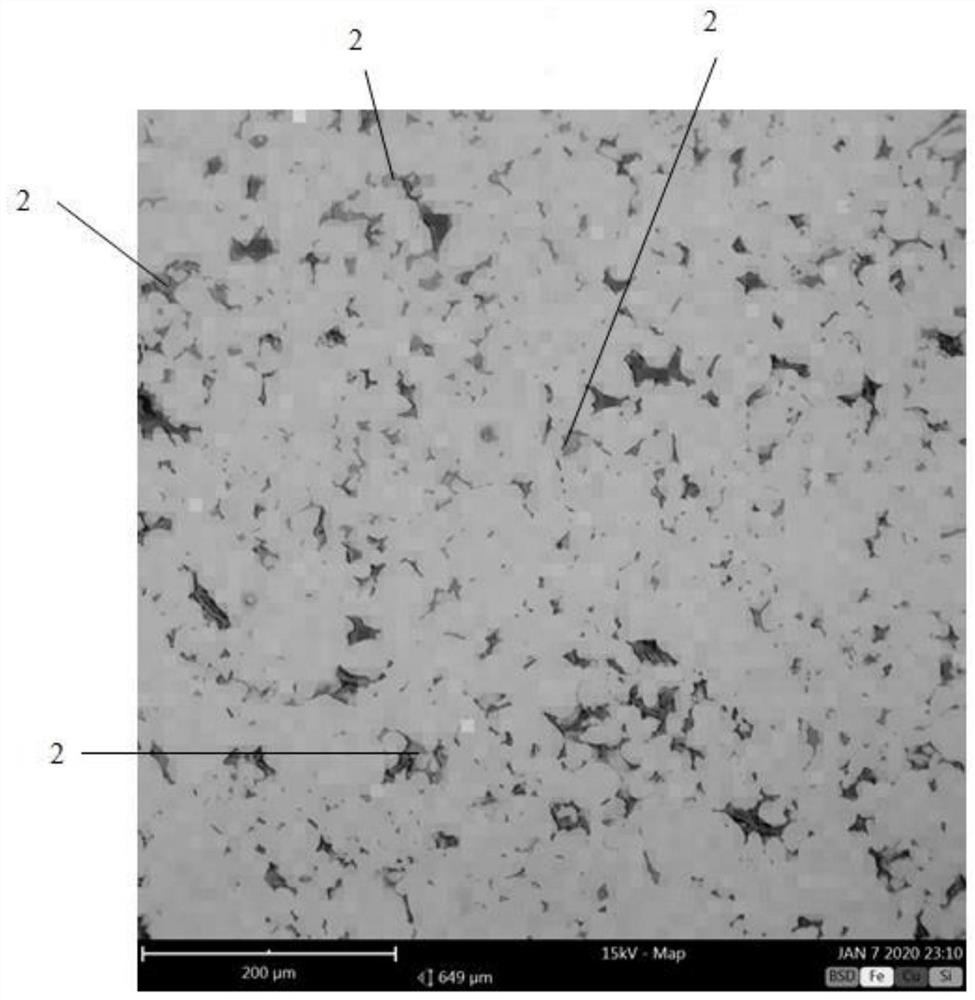

[0029] like Figure 1 to Figure 3 shown, is the first preferred embodiment of the present invention.

[0030] The sealing method of the powder metallurgy chromium alloy fuel cell connector of this embodiment includes the following steps in sequence:

[0031] 1) Prepare a suspension containing conductive particles: Dispose chromium powder suspended particles with an average particle size of 5 μm and a volume concentration of 1 vol% into water glass, and add aluminum tripolyphosphate with a volume concentration of 10% to the water glass and stir A suspension is uniformly obtained. The suspension is a pore sealing agent 1 in which chromium powder is suspended in water glass. The chromium powder is conductive and is not easily oxidized. The particle size of the suspended matter is less than 10 μm. The volume concentration of the suspended particles in the suspension is 10vol %;

[0032] 2) Place the connector to be sealed in a prepared suspension of 1 vol% chrome powder water gl...

Embodiment 2

[0039] The method for sealing holes of a powder metallurgy chrome alloy fuel cell connector in this embodiment includes the following steps in sequence:

[0040] 1) Configure a suspension containing conductive particles: configure the suspended particles of chromium powder with a volume concentration of 3 vol% into water glass, and add aluminum tripolyphosphate with a volume concentration of 0.5 vol% to the water glass and stir to obtain a suspension. , the suspension is a pore sealing agent in which chromium powder is suspended in water glass, the chromium powder is conductive and is not easily oxidized particles, the particle size of the suspended matter is less than 10 μm, and the volume concentration of the suspended particles in the suspension is 0.5vol%;

[0041] 2) Place the connector to be sealed in the prepared 3vol% chrome powder water glass suspension, then place the suspension with the connector in a vacuum with a pressure of 10000Pa and let stand for 60min at room ...

Embodiment 3

[0046] The method for sealing holes of a powder metallurgy chrome alloy fuel cell connector in this embodiment includes the following steps in sequence:

[0047] 1) Configure a suspension containing conductive particles: configure 1.5vol% of 434 stainless steel powder suspended particles into water glass, and add 0.5vol% of calcium tripolyphosphate to the water glass and stir to obtain a suspension. It is a pore sealing agent for 434 stainless steel powder suspended in water glass. 434 stainless steel powder is conductive and is not easy to be oxidized. The particle size of the suspended matter is less than 10μm, and the volume concentration of the suspended particles in the suspension is 7vol%;

[0048] 2) The connector to be sealed is placed in a prepared suspension of 1.5vol% 434 stainless steel powder water glass, and then the suspension with the connector is placed in a vacuum with a pressure of 40000Pa and kept at room temperature. Set for 60min, at this time the connect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap