Injection-molded integrated multi-color thermoplastic elastomer foamed shoe sole and manufacturing method thereof

A thermoplastic elastomer and thermoplastic elastic technology, applied in the direction of shoe soles, footwear, footwear, etc., can solve the problems of uneven particle distribution, difficult color separation effect, etc., achieve good cushioning and shock absorption effect, not easy to damage, and reduce the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

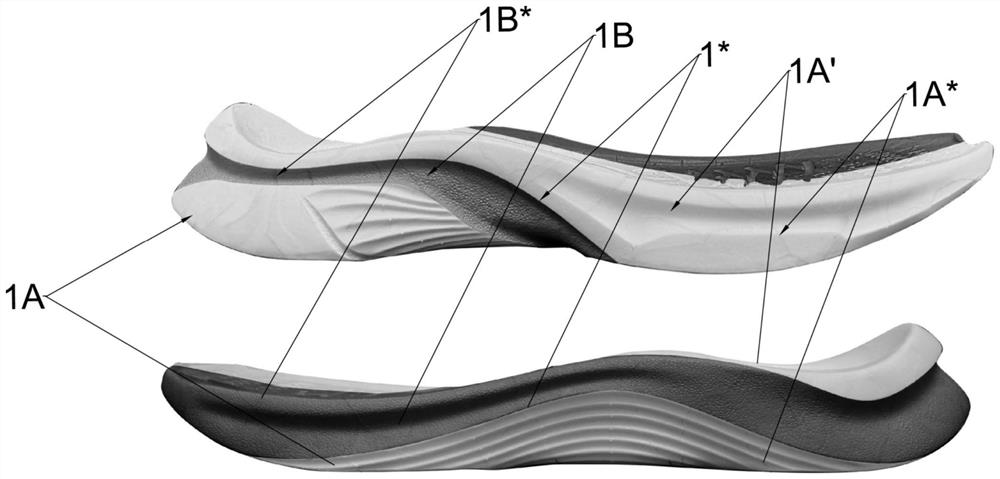

[0036] Such as figure 1 As shown, the invention discloses a method for manufacturing an injection-molded integral multi-color thermoplastic elastomer foam sole, comprising the following steps:

[0037] In the present embodiment, the A color grouping ingredients are as follows:

[0038] Thermoplastic elastomer raw material A: TPU (thermoplastic polyurethane elastomer);

[0039]Lubricant A: talcum powder;

[0040] Foaming aid A: SaKai F-190D;

[0041] Gas blowing agent A: carbon dioxide and / or isopentane;

[0042] Wherein, the additive amount percentages of lubricant A, foaming aid A, and gas foaming agent A are all based on the total mass of thermoplastic elastomer raw material A;

[0043] B color grouping ingredients are as follows:

[0044] Thermoplastic elastomer raw material B: calculated by mass ratio, TPU (thermoplastic polyurethane elastomer): TPEE (thermoplastic polyester elastomer) = 3:1;

[0045] Lubricant B: wax powder;

[0046] Foaming aid B: SaKai FN-105;

...

Embodiment 2

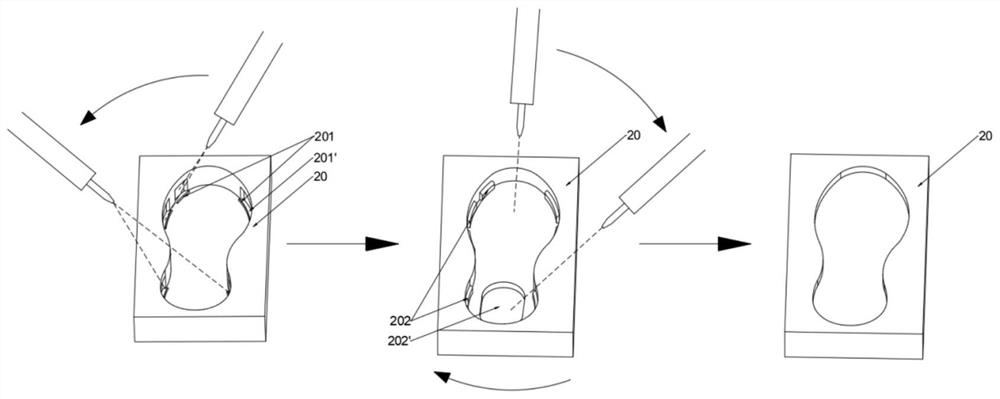

[0063] Such as Figure 2-3 As shown, the invention discloses a method for manufacturing an injection-molded integral multi-color thermoplastic elastomer foam sole, comprising the following steps:

[0064] In the present embodiment, the B color grouping ingredients are as follows:

[0065] A color grouping ingredients are as follows:

[0066] Thermoplastic elastomer raw material A: calculated by mass ratio, TPO (thermoplastic polyester elastomer): TPEE (thermoplastic polyester elastomer) = 4:1;

[0067] Lubricant A: wax powder;

[0068] Foaming aid A: SaKai FN-100;

[0069] Gas blowing agent A: nitrogen, carbon dioxide, dimethyl ether;

[0070] Wherein, the additive amount percentages of lubricant A, foaming aid A, and gas foaming agent A are all based on the total mass of thermoplastic elastomer raw material A;

[0071] Thermoplastic elastomer raw material B: TPU (thermoplastic polyurethane elastomer);

[0072] Lubricant B: talcum powder;

[0073] Foaming aid B: SaKai F...

Embodiment 3

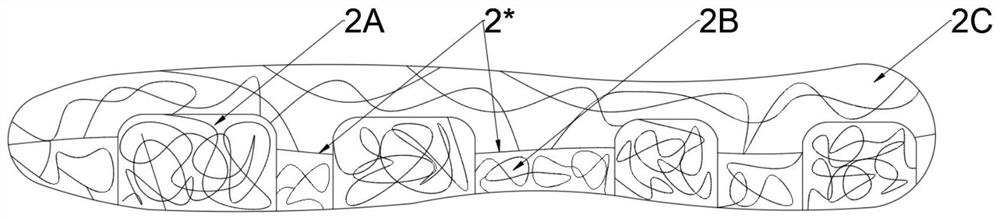

[0100] The invention discloses a method for manufacturing an injection-molded integrated multi-color thermoplastic elastomer foam sole, which comprises the following steps:

[0101] In the present embodiment, the B color grouping ingredients are as follows:

[0102] A color grouping ingredients are as follows:

[0103] Thermoplastic elastomer raw material A: calculated by mass ratio, TPU (thermoplastic polyolefin elastomer);

[0104] Lubricant A: oligomeric fatty acid ester

[0105] Foaming aid A: HFC-245FA

[0106] Gas blowing agent A: carbon dioxide, dimethyl ether;

[0107] Wherein, the additive amount percentages of lubricant A, foaming aid A, and gas foaming agent A are all based on the total mass of thermoplastic elastomer raw material A;

[0108] Thermoplastic elastomer raw material B: TPU (thermoplastic polyolefin elastomer): TPAE (thermoplastic polyester elastomer) = 4:1;

[0109] Lubricant B: non-polar PE wax

[0110] Foaming aid B: HFC-245FA

[0111] Gas blow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com