Automatic lifting device for urban sewage pipeline installation

A technology for automatic lifting of sewage pipes, applied in the direction of lifting devices, lifting frames, workbenches, etc., can solve the problems of clamping and fixing pipes of different sizes, sloshing of sewage pipes, accidents, etc., achieving strong versatility and reducing The effect of working strength and convenient clamping and fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

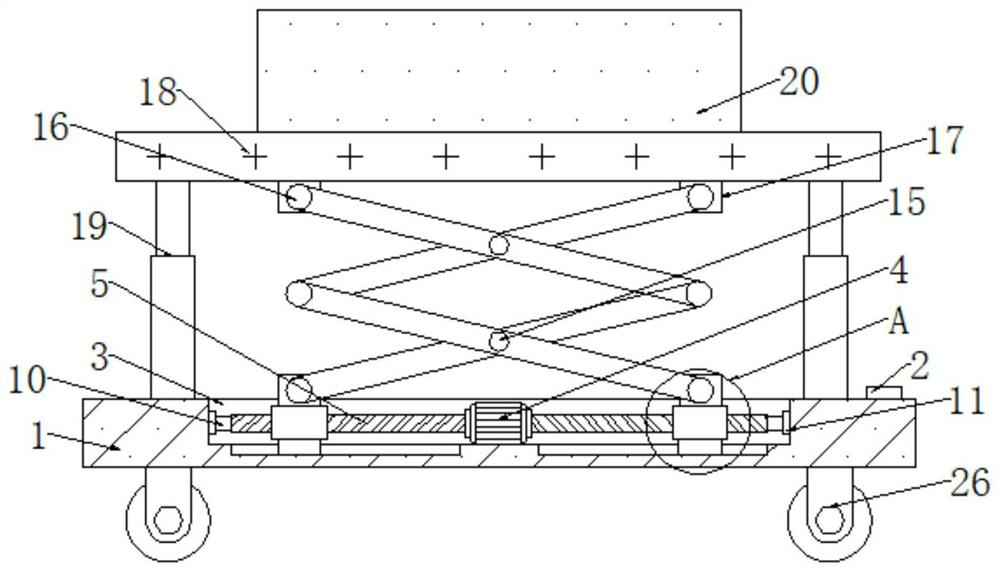

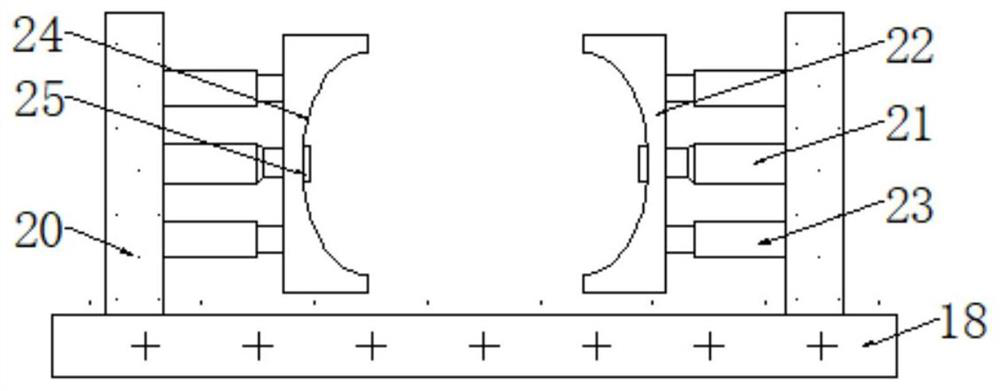

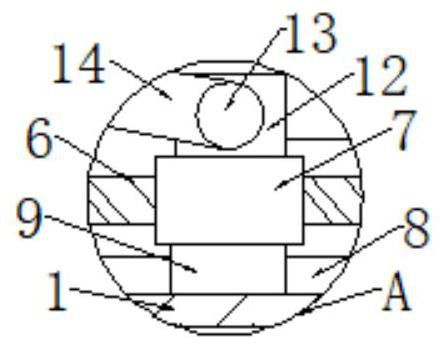

[0021] see Figure 1-3 , the present invention provides the following technical solutions: an automatic lifting device for urban sewage pipeline installation, including a first support plate 1, a groove 3 is opened in the first support plate 1, and a groove 3 is fixedly connected in the groove 3. Biaxial motor 4, the first screw mandrel 5 and the second screw mandrel 6 are fixedly connected on the two output shafts of the said biaxial motor 4, and the surfaces of the first screw mandrel 5 and the second screw mandrel 6 are screwed together There are threaded sleeves 7, the tops of the two threaded sleeves 7 are fixedly connected with the first fixed block 12, and the two first fixed blocks 12 are connected with the connecting rod 14 through the first pin shaft 13, and the two The connecting rod 14 is pierced with a third pin shaft 15, and the top ends of the two connecting rods 14 are connected to the second fixed block 17 through the second pin shaft 16, and the top ends of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com