Nuclear reactor coolant pump shaft sleeve installation technology

A coolant pump and nuclear reactor technology, which is applied to the components, pumps, and pump elements of a pumping device for elastic fluids, can solve problems such as scratches, damage to water guide bearings, and no precedent for manufacturing, and achieve practical results. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

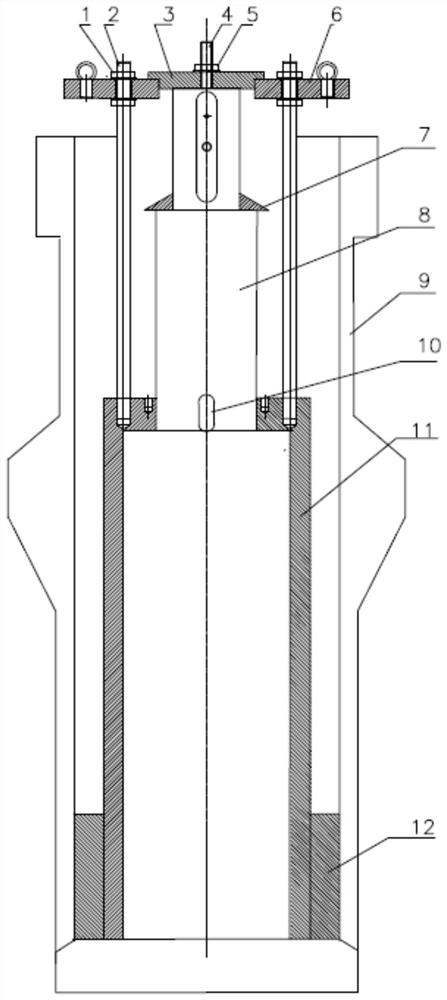

[0026] Such as figure 1 As shown, a nuclear reactor coolant pump shaft sleeve installation process uses a mounting plate 6, a long screw 2, and a nut 1 to connect the shaft sleeve 11, adjust the nut 1 to make the shaft sleeve level to 0.02mm / m, and start the crane hoisting installation The disk 6 makes the shaft sleeve 11 fall, and the guide tool 7 is used to guide and protect during the falling process of the installation disk 6 and the shaft sleeve 11. When the shaft sleeve falls 1856mm, the short screw 4 and the nut 5 do work on the compaction disk 3 to compress it The disk 3 and the mounting disk 6 cooperate with the stop to drive the mounting disk 6 and the sleeve 11 to move downwards to achieve precise positioning and installation of the sleeve 11. The above method includes the following steps:

[0027] 1) Screw the M12 long screw 2 into the sleeve 11;

[0028] 2) Nut 1 is installed on the long screw 2;

[0029] 3) The mounting plate 6 passes through the long screw 2 and is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com