Installation and adjustment process of nuclear main pump before drilling and reaming

A technology of installation and adjustment, nuclear main pump, applied in the direction of manufacturing tools, metal processing, feeding devices, etc., can solve problems such as inexperience, and achieve the effect of improving measurement accuracy, ensuring operation, and good practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

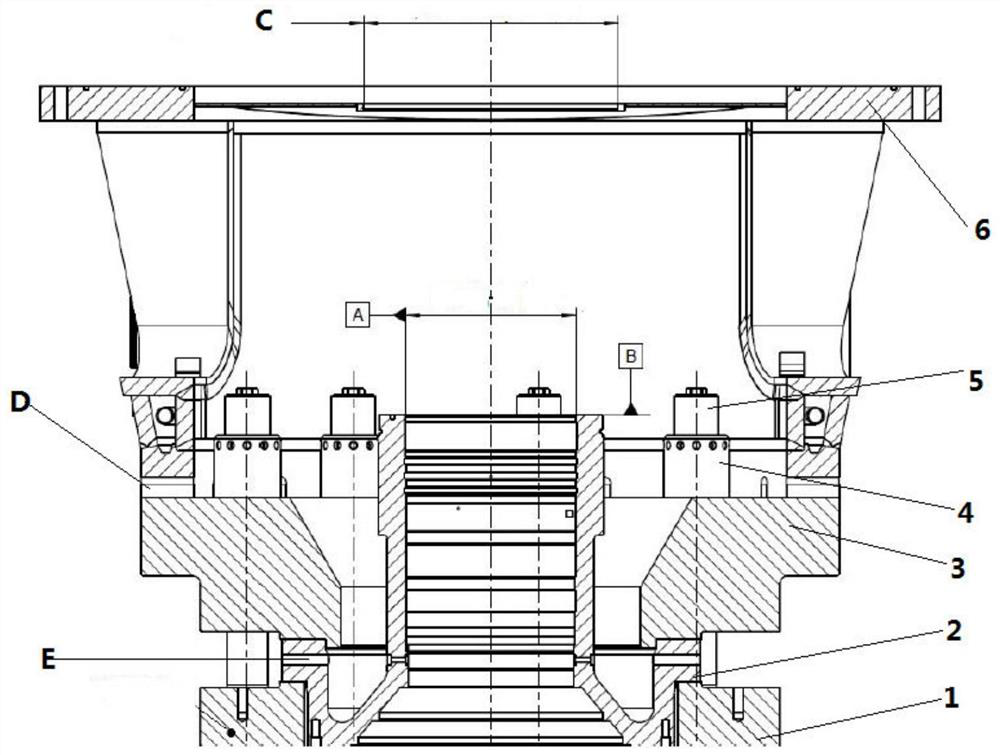

[0021] like figure 1 As shown, an installation and adjustment process of the nuclear main pump before drilling and reaming uses the seam positioning method to complete the installation and adjustment of the pump cover 3 and the sealing chamber 2, places the sealing chamber 2 at the rotation center of the machine tool, and places the lower motor support 6 Place it on the pump cover 3, adjust the center of the lower motor support 6, when the center of the lower motor support 6 coincides with the center of the sealing chamber 2, use the bolt 4 and the nut 5 to tighten the sealing chamber 2, the pump cover 3, and the lower motor at the same time Bearing 6, said method comprises the following steps:

[0022] 1) Hang the pump casing 1 on the workbench of the machine tool, and install the sealing chamber 2 in the pump casing 1;

[0023] 2) Adsorb the dial indicator on the tool bar of the machine tool, turn the machine tool table, check the radial runout of the inner diameter surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com