Nuclear Reactor Coolant Pump Shaft Sleeve Installation Process

A technology for coolant pumps and nuclear reactors, which is applied to parts, pumps, and pump components of pumping devices used for elastic fluids, and can solve problems such as peeling off of the chrome-plated surface of the lower pump shaft, deformation of the shaft sleeve and scrapping of the shaft sleeve, damage to the water guide bearing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

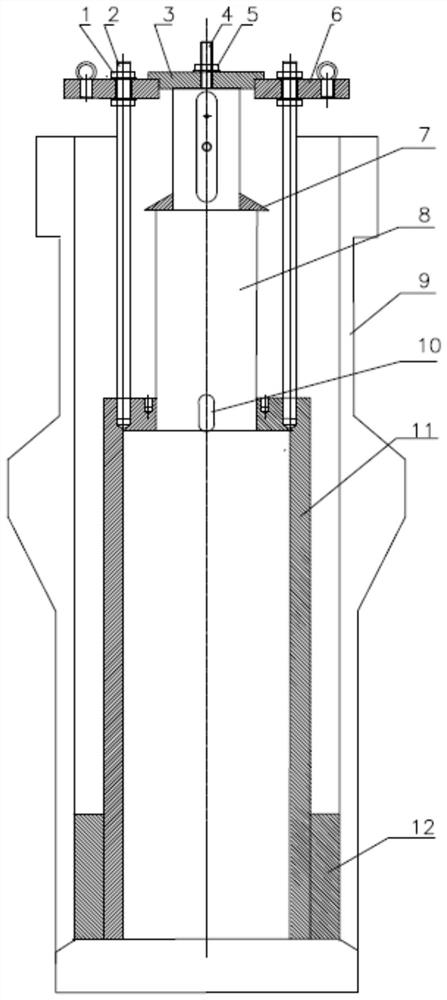

[0026] Such as figure 1 As shown, a nuclear reactor coolant pump shaft sleeve installation process uses a mounting plate 6, a long screw 2, and a first nut 1 to connect the shaft sleeve 11, adjust the first nut 1 so that the level of the shaft sleeve reaches 0.02mm / m, and start Crane hoisting installation plate 6 makes the shaft sleeve 11 fall, guide tool 7 is used to guide and protect the installation plate 6 and shaft sleeve 11 during the falling process, when the shaft sleeve falls 1856mm, the short screw rod 4 and the second nut 5 are used to compress the circle The disk 3 works, and the pressing disk 3 and the installation disk 6 drive the installation disk 6 and the shaft sleeve 11 to move downward through the joint cooperation, so as to achieve the precise positioning and installation of the shaft sleeve 11. The above method includes the following steps:

[0027] 1) The M12 long screw 2 is screwed into the bushing 11;

[0028] 2) The first nut 1 is installed on the lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com