System and method for measuring hinge angle of full trailer train

A technology for automobile trains and measurement systems, which is applied in the field of measurement systems for the articulation angle of full-trailer automobiles and trains. It can solve the problems of inconvenient use, high requirements for the test environment, and inability to monitor costs in real time, and achieves avoidance of damage, low requirements for the test environment, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

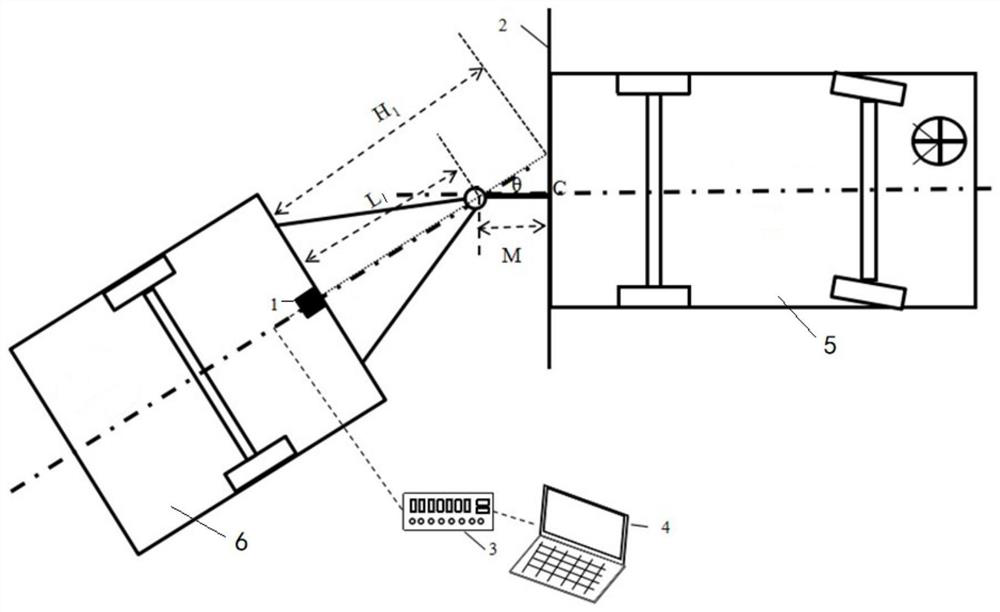

[0107] Such as figure 1 As shown, the present embodiment provides a measurement system for the articulation angle of a full-trailer train, including a tractor 5, a trailer 6, a laser rangefinder 1, a reflector 2, a data acquisition instrument 3 and a data analyzer 4, and the traction The car 5 is connected to the trailer 6; the thickness of the reflecting plate 2 is 2 millimeters;

[0108] A laser range finder 1 is arranged on the front end of the trailer 6. The laser range finder 1 includes a launch end, and the launch end is arranged on the front end of the trailer 6. The center point of the launch end of the laser range finder 1 is positioned at the longitudinal symmetry of the trailer 6. In-plane; the reflector 2 is arranged at the rear end of the tractor 5; the laser rangefinder 1 is used to emit laser light perpendicular to the front end of the trailer 6 facing the reflector 2, and measure that the laser reaches the reflector 2 from the front end of the trailer 6 distan...

Embodiment 2

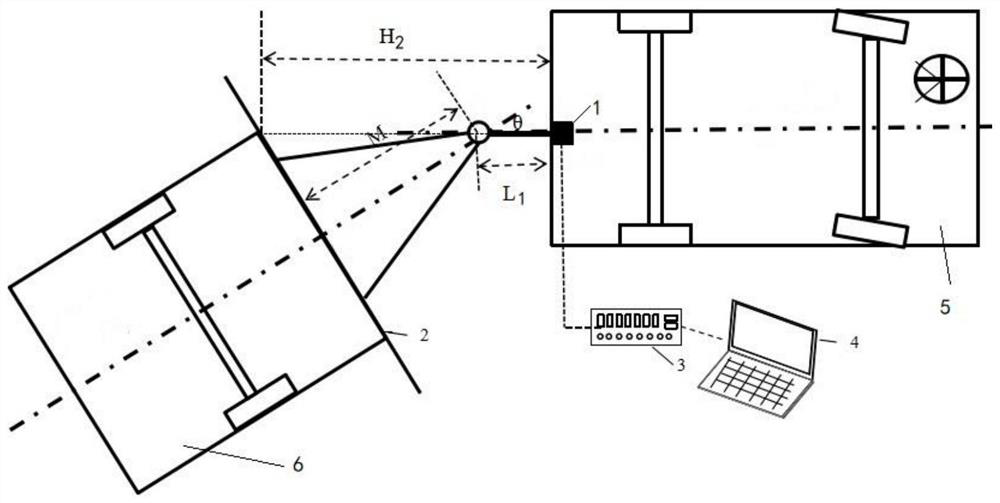

[0115] Such as figure 2 As shown, the present embodiment provides a measurement system for the articulation angle of a full-trailer train, including a tractor 5, a trailer 6, a laser rangefinder 1, a reflector 2, a data acquisition instrument 3 and a data analyzer 4, and the traction The car 5 is connected to the trailer 6; the thickness of the reflecting plate 2 is 4 mm;

[0116] The laser range finder 1 is arranged on the rear end of the tractor 5, and the laser range finder 1 includes a launch end, and the launch end is arranged on the rear end face of the tractor 5, and the center point of the launch end of the laser range finder 1 is located at the tractor 5 The reflector 2 is arranged on the rear end of the trailer 6; the laser range finder 1 is used to emit laser light perpendicular to the rear end of the tractor 5 facing the reflector 2, and measure the laser distance from the rear end of the tractor 5. The distance from the end surface to the reflector 2.

[0117] ...

Embodiment 3

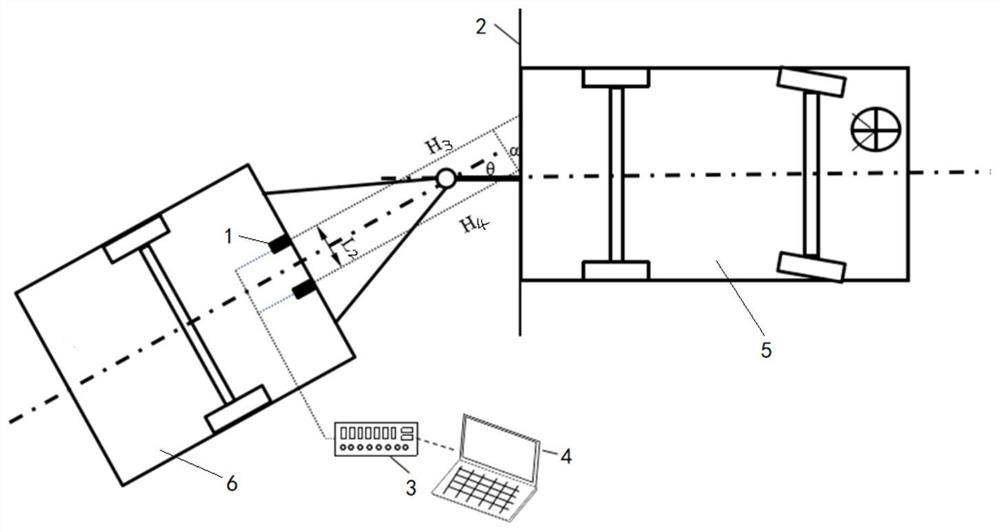

[0123] Such as image 3 As shown, the present embodiment provides a measurement system for the articulation angle of a full-trailer train, including a tractor 5, a trailer 6, two laser range finders 1, a reflector 2, a data acquisition instrument 3 and a data analyzer 4, The tractor 5 is connected to the trailer 6; the thickness of the reflecting plate 2 is 6 millimeters;

[0124] The two laser range finders 1 are all arranged on the front end of the trailer 6, the laser range finder 1 includes a launch end, the launch end is arranged on the front end of the trailer 6, and the center points of the launch ends of the two laser range finders 1 are respectively located at The two parallel planes of the longitudinal symmetry plane of the trailer 6; the reflector 2 is arranged on the rear end of the tractor 5; the laser rangefinder 1 is used to emit laser light perpendicular to the front end of the trailer 6 facing the reflector 2, and measure the laser The distance traveled from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com