Deflection compensation type multi-spindle machining center

A machining center and spindle machining technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve problems such as workpiece machining deviation, achieve the effect of ensuring machining accuracy and overcoming thermal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

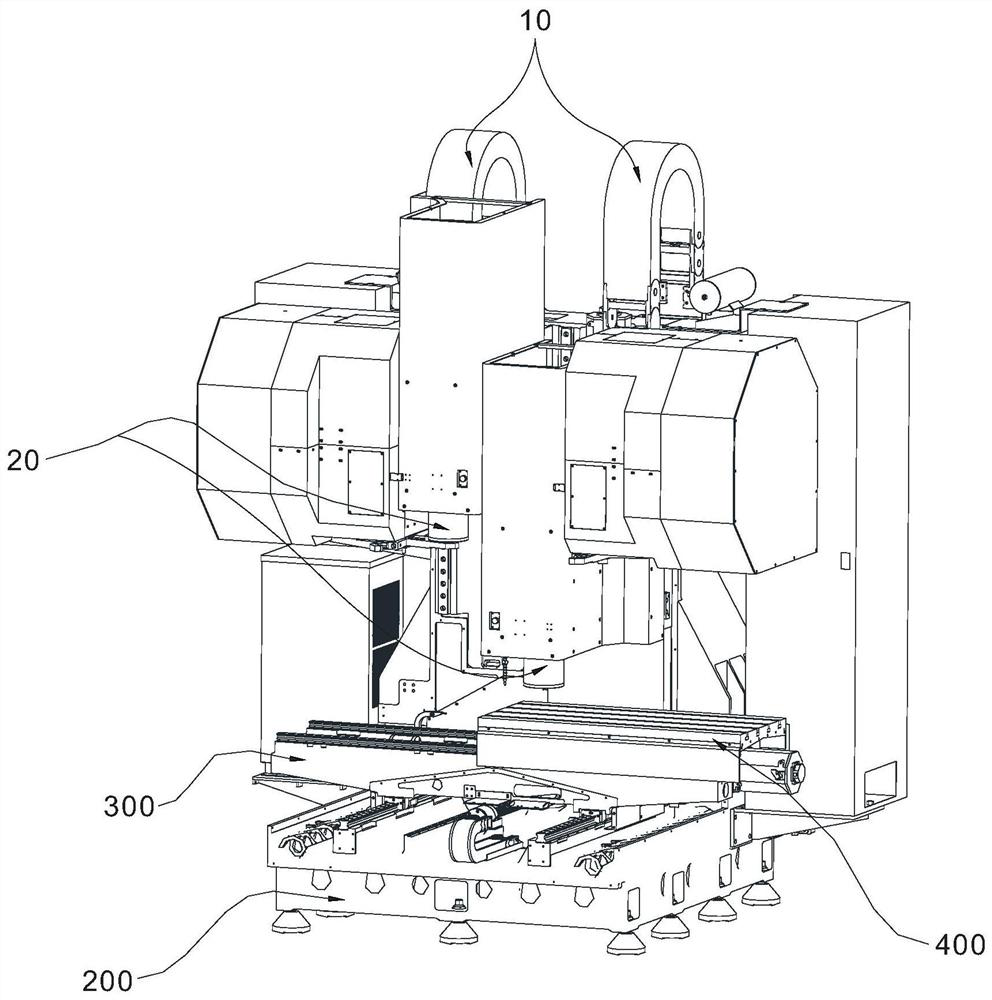

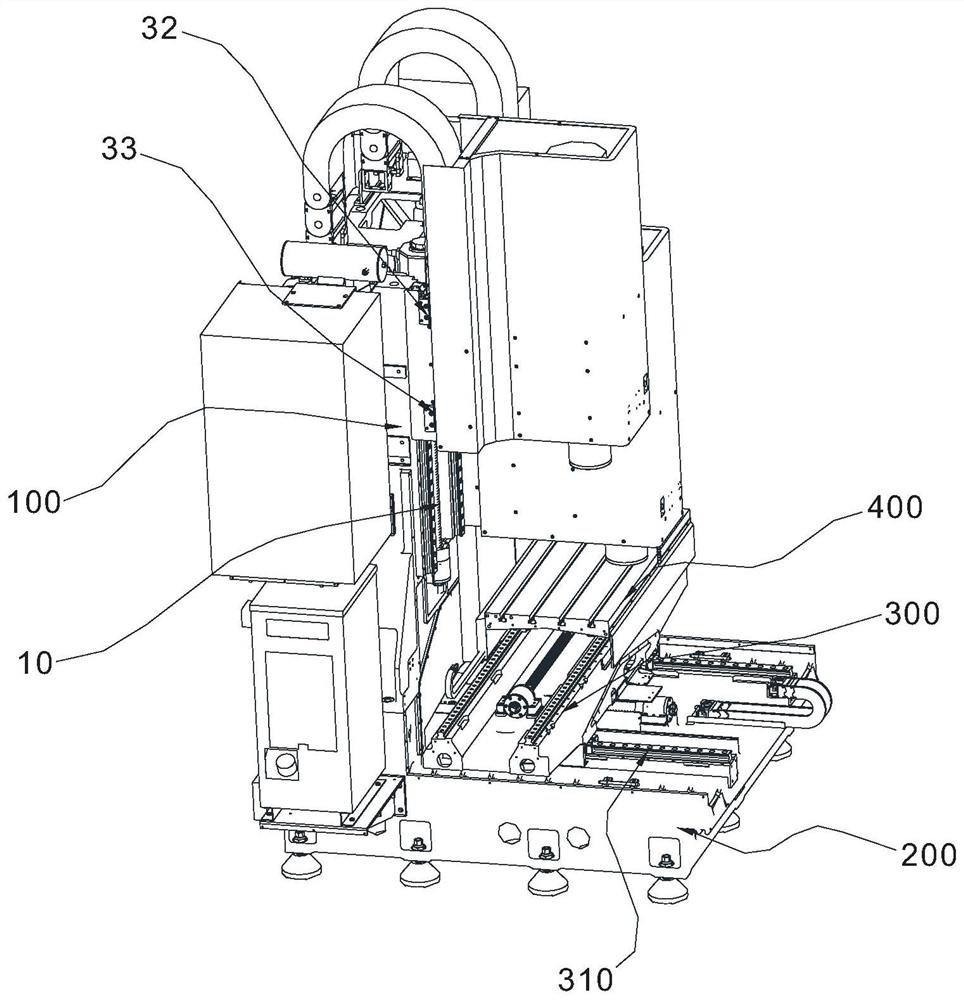

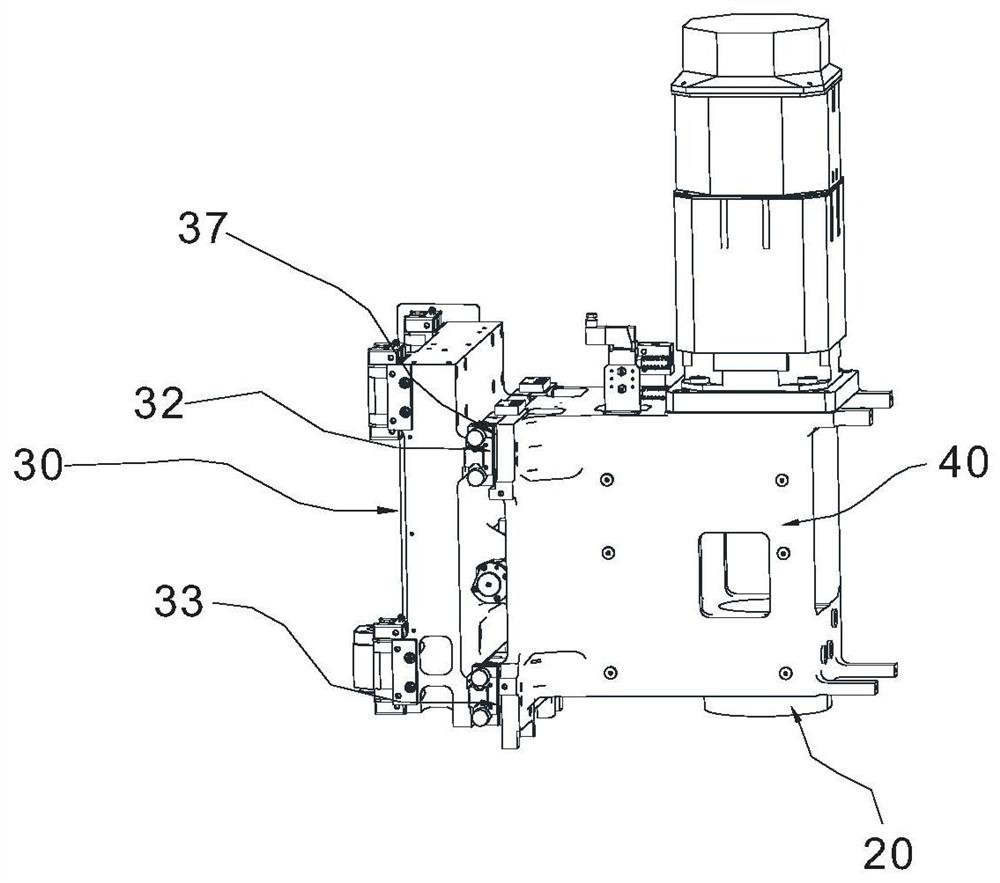

[0023] like Figure 1 to Figure 5 As shown, a displacement compensation multi-spindle machining center includes a main base 200, a main column 100, a saddle 300, a worktable 400, two spindle processing units, and a workpiece pallet exchange mechanism. The main column 100 is fixed on the main base 200 and is perpendicular to the ground, and a honeycomb lattice structure is arranged inside the main column 100 . The spindle processing unit is slidably connected to the main column 100, the saddle 300 is slidably connected to the main base 200, the Y-axis driving mechanism 310 is connected between the saddle 300 and the main base 200, the workbench 400 is slidably connected to the saddle 300, and the saddle 300 is slidably connected to the main base 200. The seat 300 is connected to the Y-axis driving mechanism 310 , and the X-axis driving mechanism is connected between the workbench 400 and the saddle 300 . The spindle processing unit includes a spindle 20 , an X-axis displacemen...

Embodiment 2

[0026] There are three spindle processing units. All the other are with embodiment 1.

Embodiment 3

[0028] There are four spindle processing units. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com