Method for remanufacturing blast furnace copper air port

A remanufacturing and blast furnace technology, applied in the remanufacturing field of blast furnace copper tuyere, can solve the problems of scrapping, high price, large heat input, etc., and achieve the effects of low surface roughness, improved service life, and dense welding layer structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

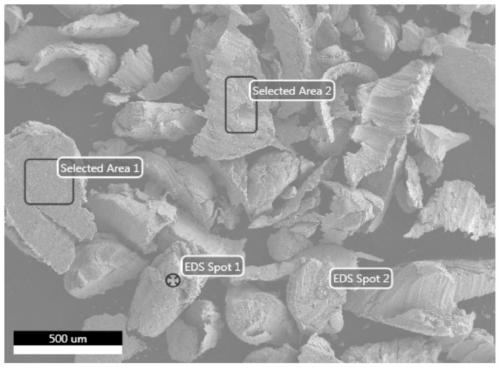

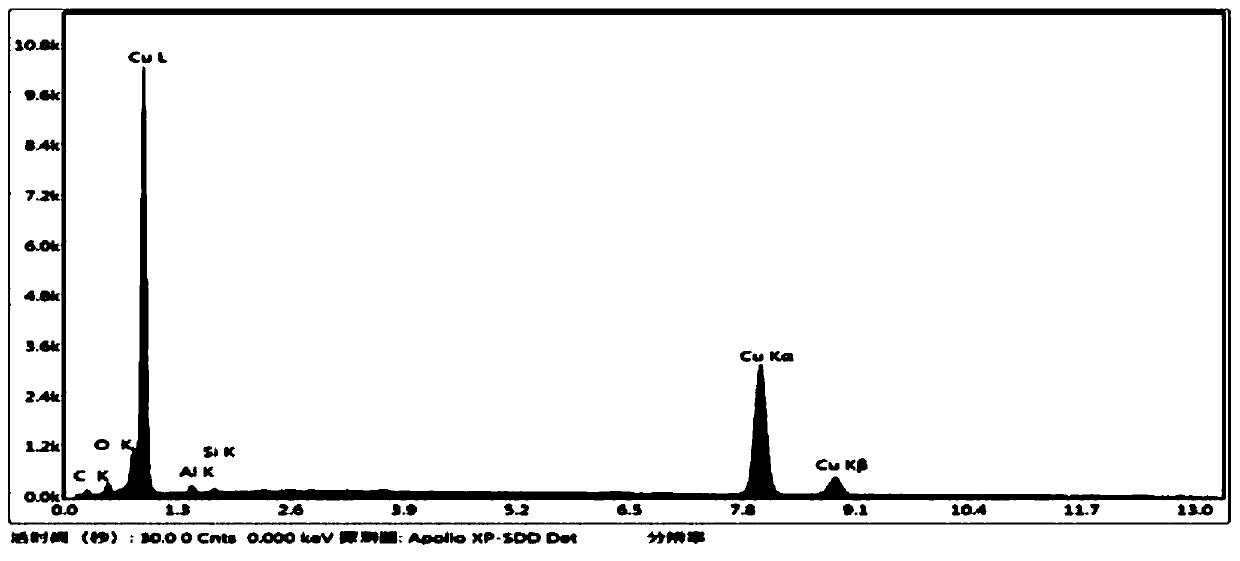

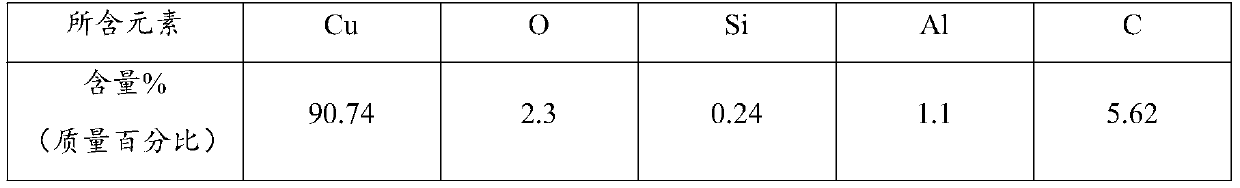

Image

Examples

Embodiment 1

[0041] (1) The outer surface and the inner wall of the copper tuyere to be repaired are machined, and the single-side processing amount of the machining is 1mm, and then the outer surface and the inner wall of the copper tuyere are cleaned with absolute ethanol;

[0042] (2) CMT welding is carried out to the outer surface and the inner wall of the blast furnace copper tuyere after cleaning, and the used welding wire of CMT welding is copper welding wire HSCu, and the diameter of described copper welding wire HSCu is 1.6mm; The welding torch used for welding is an extension welding torch, and the extension length of welding torch The welding current is 100A, the welding voltage is 8V, the wiring method is DC reverse connection, and the welding speed is 150mm / min, and the CMT welding of the outer surface is 130A. , the welding voltage is 10V, the wiring mode during welding is DC reverse connection, and the welding speed is 190mm / min; the shielding gas of CMT welding is argon (pur...

Embodiment 2

[0046] (1) Machining the outer surface and inner wall of the copper tuyere to be repaired, the single-side processing amount of the machining is 2mm; use absolute ethanol to clean the outer surface and inner wall of the copper tuyere;

[0047] (2) CMT welding is carried out to the outer surface and inner wall of the blast furnace copper tuyere after cleaning, and the used welding wire of CMT welding is copper welding wire HSCu, and the diameter of described copper welding wire HSCu is 1.6mm; The welding torch used for welding is an extension welding torch, and the extension length of welding torch is 3000mm; Among them, for CMT welding on the inner wall, the welding current is 120A, the welding voltage is 11V, the wiring method during welding is DC reverse connection, and the welding speed is 180mm / min; for the CMT welding on the outer surface, the welding current is 150A, The welding voltage is 12V, the wiring mode during welding is DC reverse connection, and the welding speed...

Embodiment 3

[0051] (1) Machining the outer surface and inner wall of the copper tuyere to be repaired, the single-side processing amount of the machining is 1.2mm; use absolute ethanol to clean the outer surface and inner wall of the copper tuyere;

[0052] (2) CMT welding is carried out to the outer surface and inner wall of the blast furnace copper tuyere after cleaning, and the used welding wire of CMT welding is copper welding wire HSCu, and the diameter of described copper welding wire HSCu is 1.6mm; The welding torch used for welding is an extension welding torch, and the extension length of welding torch is 2500mm; Among them, for CMT welding on the inner wall, the welding current is 100A, the welding voltage is 8V, the wiring method during welding is DC reverse connection, and the welding speed is 150mm / min; for the CMT welding on the outer surface, the welding current is 130A, The welding voltage is 10V, the connection mode during welding is DC reverse connection, and the welding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com