Flushing-free toilet structure and fixed and lifting type flushing-free toilet system

A flush-free, lifting mechanism technology, applied in the direction of engine room flushing devices, applications, vehicle sanitary equipment, etc., to achieve the effects of saving water resources, reasonable structural design, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

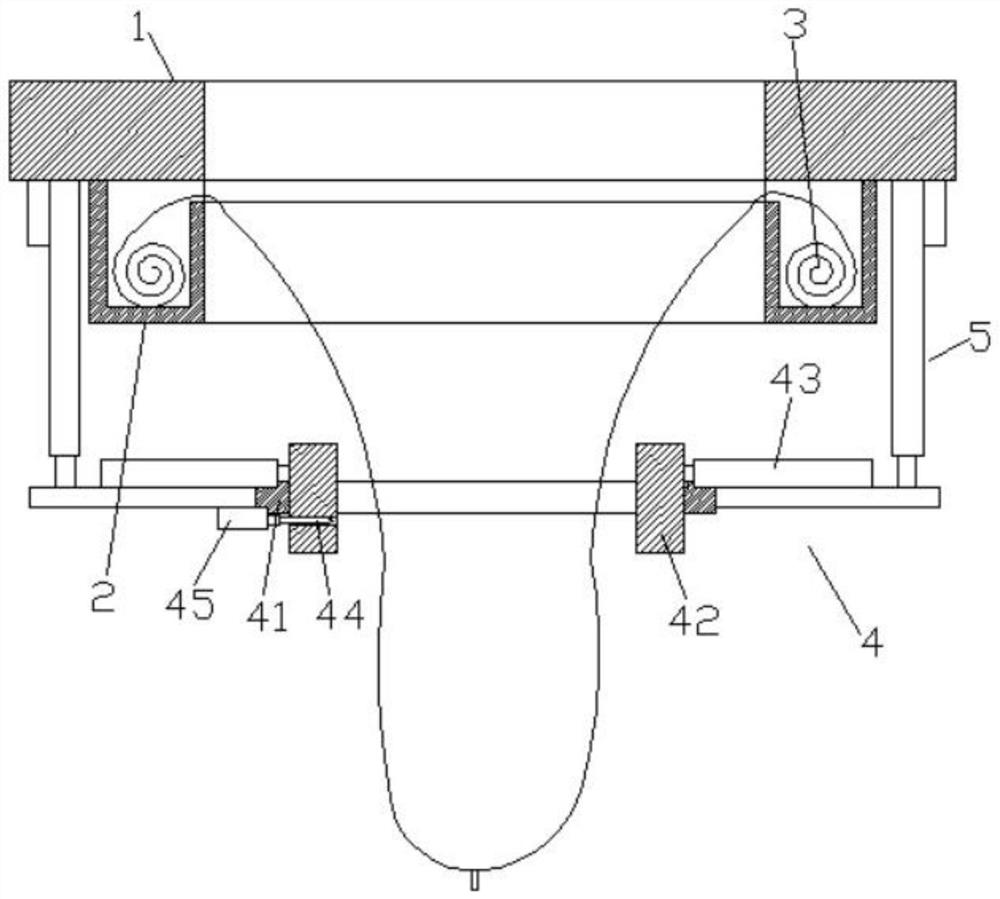

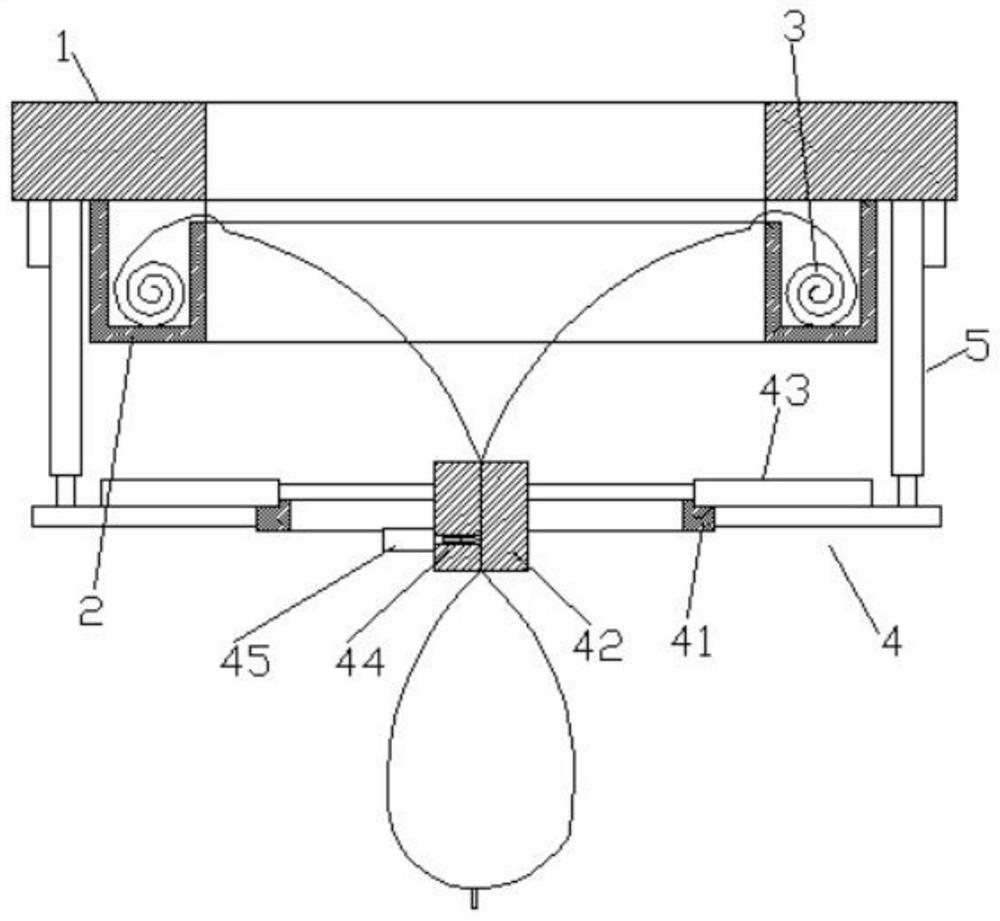

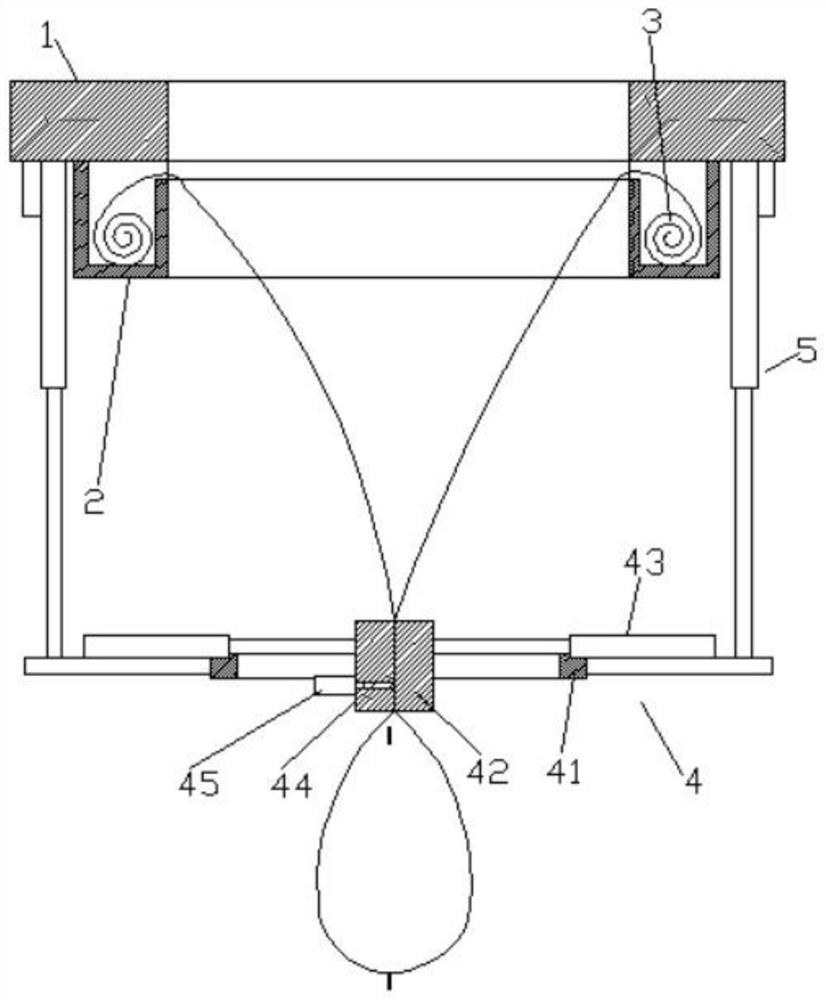

[0047] Embodiment one: if Figures 1 to 3 As shown, the non-flush toilet structure of this embodiment includes an annular squatting basin panel 1, an annular box body 2, a packaging bag 3 and a hot-melt sealing mechanism 4, the above-mentioned box body 2 matches the above-mentioned squatting basin panel 1, and It is detachably assembled on the lower end of the above-mentioned squatting basin panel 1, and the inner side of the above-mentioned box body 2 is provided with an annular packaging bag outlet. The bag outlet is pulled out and extends downwards. The above-mentioned hot-melt sealing mechanism 4 is installed on the lower end of the above-mentioned squatting basin panel 1 through the telescopic mechanism 5. The above-mentioned telescopic mechanism 5 is used to drive the above-mentioned hot-melt sealing mechanism 4 to move up and down. The above-mentioned hot-melt sealing The mechanism 4 is used to sequentially seal the packaging bags 3 passing through it into independent b...

Embodiment 2

[0065] Embodiment two: if Figure 6 As shown, this embodiment provides a fixed flush-free toilet system, including the flush-free toilet structure as in Embodiment 1, and the squatting basin panel 1 is fixedly installed above the ground.

[0066] In this embodiment, the squatting basin panel 1 is fixed above the ground, and is generally used for toilet sitting.

[0067] As a preferred embodiment, a reversible toilet seat 11 is rotatably connected to the upper edge of the squatting basin panel 1 .

[0068] In this embodiment, the toilet seat 11 is turned over for use, and it only needs to be turned over until it sticks to the upper surface of the squatting basin panel 1 when sitting in the toilet.

Embodiment 3

[0069] Embodiment three: as Figure 7 , 8 , 9, and 10, the present embodiment provides a lifting type non-flushing toilet system, including a lifting mechanism 6 and the structure of a non-flushing toilet as in Embodiment 1, and the lower end of the squatting basin panel 1 is installed on the on the ground.

[0070] In this embodiment, the lifting mechanism 6 can drive the squatting basin panel 1 to adjust its height, so that the squatting basin panel 1 can be used by people of different heights.

[0071] As a preferred embodiment, a groove area is provided on the ground below the above-mentioned squatting basin panel 1, and the above-mentioned lifting mechanism 6 is installed on the bottom wall in the above-mentioned groove area, and the above-mentioned lifting mechanism 6 can drive the above-mentioned squatting basin 1 to The downward movement is contracted into the above-mentioned groove area, or the upward movement is above the above-mentioned groove area.

[0072] In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com