Switch machine point rail position monitoring system with redundant configuration and switch machine

A technology of redundant configuration and monitoring system, applied in the direction of locking mechanism for turnout, electrical equipment for operating turnout or line interrupter, railway signal, etc. Column blocking and other problems, to achieve the effect of simple circuit design, reduction of manual maintenance, and avoidance of misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

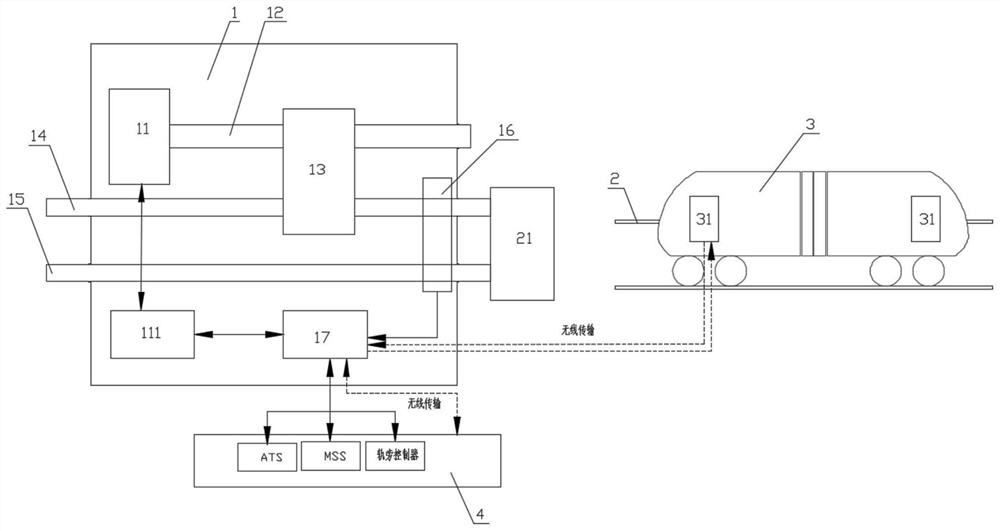

[0031] refer to Figure 1 to Figure 4 As shown, an intelligent switch machine 1 that can be independently controlled by the train. The train runs on the track 2. The switch machine 1 controls the point rail 21 of the switch to change the position of the switch. Remotely control the switch machine 1. It includes a switch machine driving device, a switch machine position indicating device, a sensor group 16 and a core processing board 17 . The switch machine driving device includes a motor 11, a transmission mechanism 12, and an action lever 14. The motor 11 drives the action lever 14 through the transmission mechanism 12, and the action lever 14 drives the switch point rail 21 to move.

[0032] Wherein, the switch machine position display device includes a display rod 15 and a display rod monitoring sensor, the display rod 15 is connected with the switch switch rail 21, and the action rod 14 pushes the switch switch rail 21 to move, and then the display rod 15 moves along with...

Embodiment 2

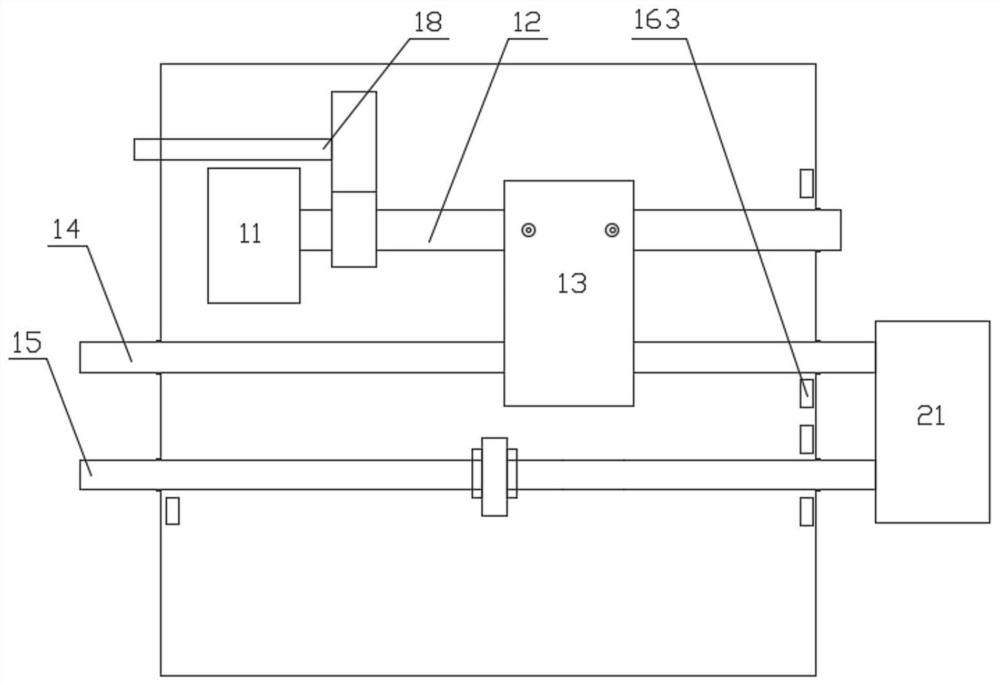

[0048] If the switch machine 1 breaks down, the motor 11 cannot drive the action lever 14 to reset. Such as figure 2 As shown, the switch machine 1 is provided with a gear mechanism 18, the gear mechanism 18 is connected with the self-locking transmission mechanism, and the gear mechanism 18 is connected with the handle, so that when the switch machine 1 breaks down, the action rod 14 can be manually reset by shaking the handle. .

Embodiment 3

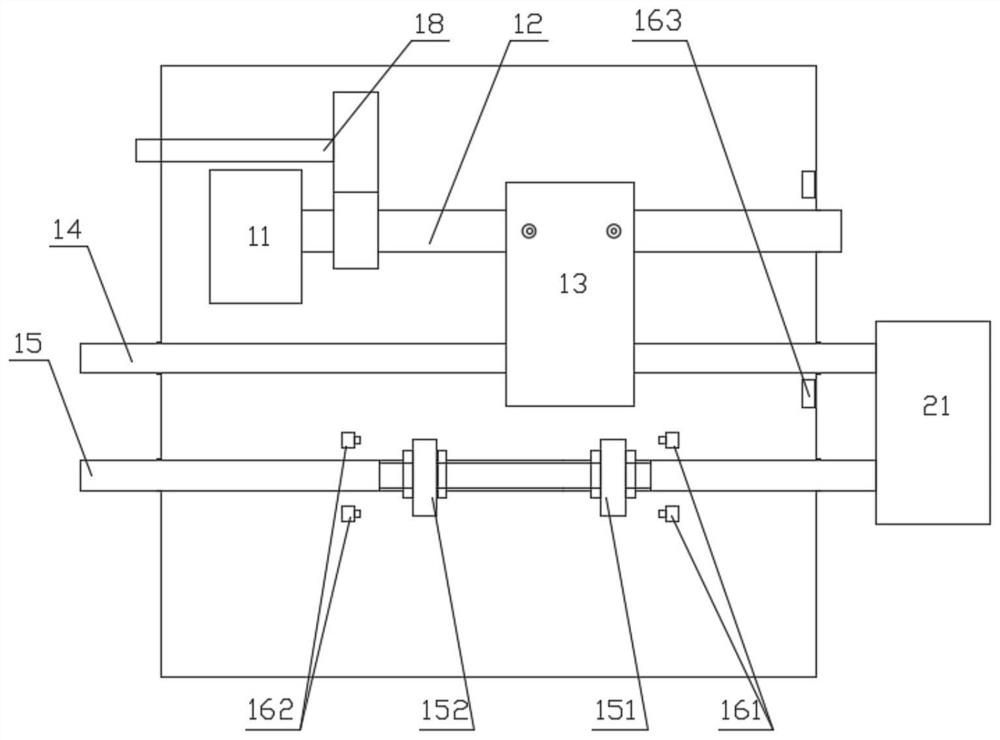

[0050] Such as image 3 As shown, in this embodiment, the indicator rod monitoring sensor is a travel switch, the positive position locking member 151 and the reverse position locking member 152 are installed on the indicating rod 15, and the corresponding normal position locking The piece 151 is provided with a positive position travel switch 161 , and the corresponding reverse position locking piece 152 is provided with a reverse position travel switch 162 . The normal position locking member 151 is used to trigger the normal position travel switch 161 of the indicating rod to monitor the normal position of the indicating rod 15 . The reverse position locking member 152 is used to trigger the reverse travel switch 162 of the indicator rod to monitor the reverse position of the indicator rod 15 .

[0051] Optionally, there are two forward travel switches 161 which are mutually redundant, and two reverse travel switches 162 are also provided with two mutually redundant.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com