Rotary type wet blank transfer device

A transfer device, rotary technology, applied in the direction of lifting device, transportation and packaging, conveyor objects, etc., to achieve the effect of low manufacturing and use comprehensive cost, easy and convenient installation, assembly and maintenance, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

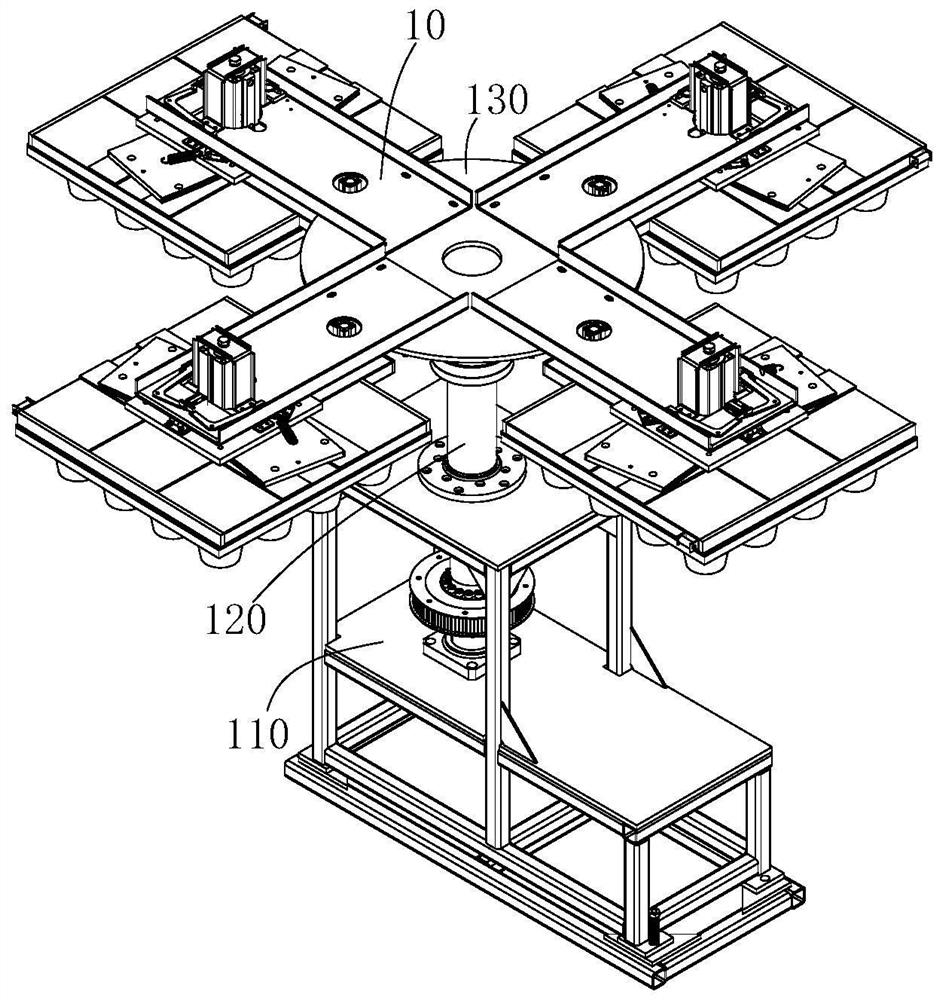

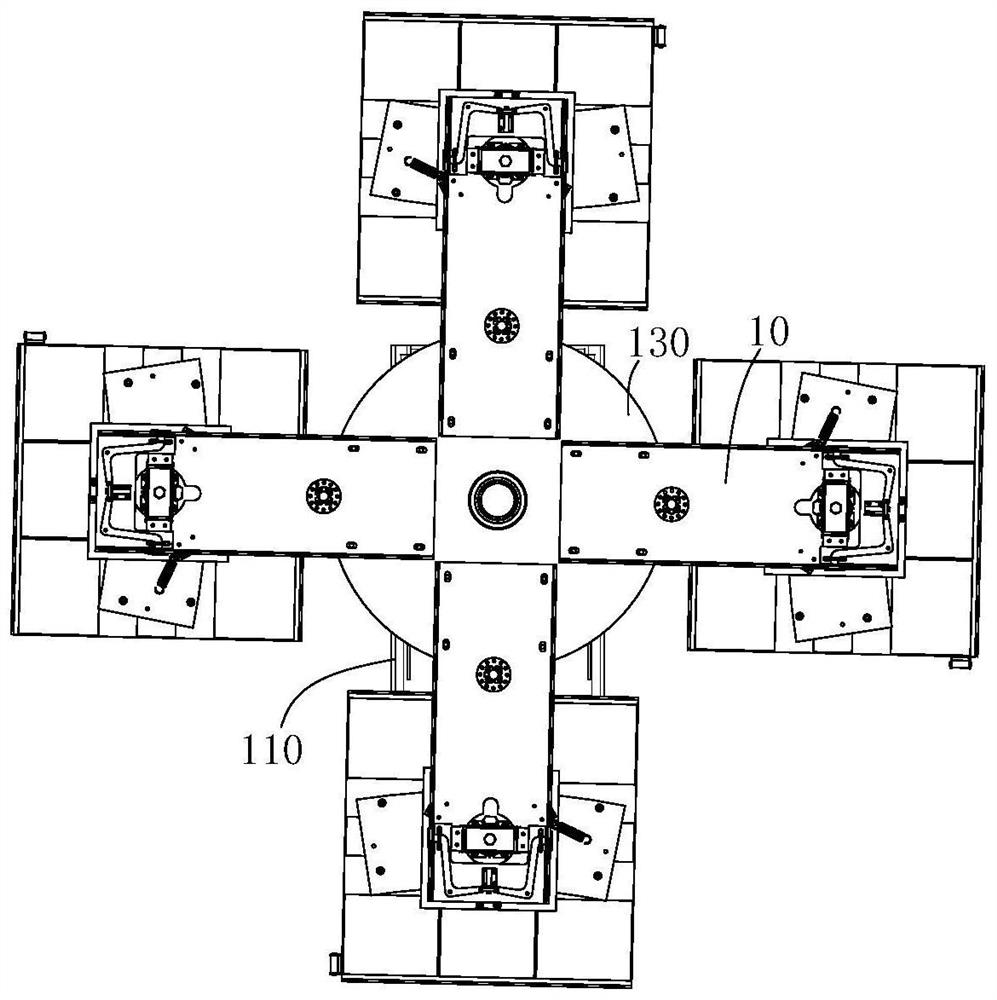

[0049] Please refer to Figure 1-12 , this embodiment provides a rotary wet embryo transfer device, including a support frame 110, a rotating shaft 120, and a rotating arm mounting seat 130; the rotating shaft is vertically installed on the supporting frame, and the rotating arm is installed The seat 130 is fixedly installed on the upper part of the rotating shaft, and the rotating arm mounting seat 130 can rotate around the axis of the rotating shaft; the rotating arm mounting seat 130 is equipped with four wet embryo transfer arm structures evenly distributed along its circumference;

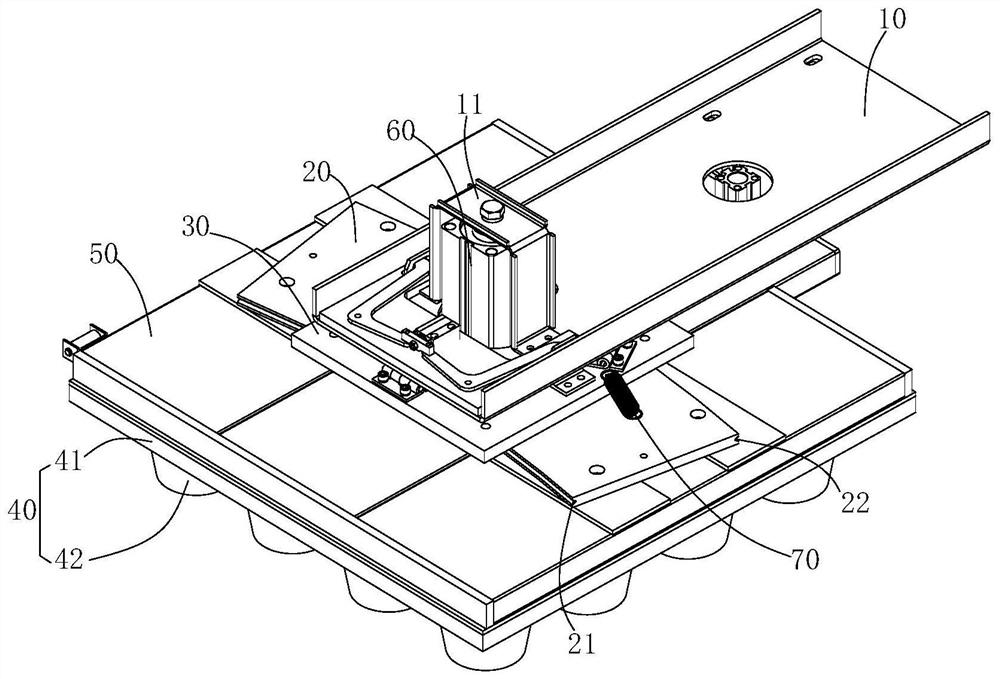

[0050] Described wet embryo transfer arm structure comprises wet embryo transfer arm 10, wet embryo adsorption mold 40 and lifting drive mechanism; One end of described wet embryo transfer arm is fixedly installed on the described rotating arm mount, and its other end is installed from rotating arm The seat protrudes outwards to form an extended end; the wet embryo adsorption mold is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com