Device for paving waterproof coiled material of basement

A waterproof membrane and laying device technology, applied in the direction of roofing, building, building structure, etc., can solve the problems that hinder the safe and smooth construction of the basement project, affect the quality of the post-casting belt construction, and the height of the outer wall is different, and achieve the applicable The effect of wide range, fast laying speed and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

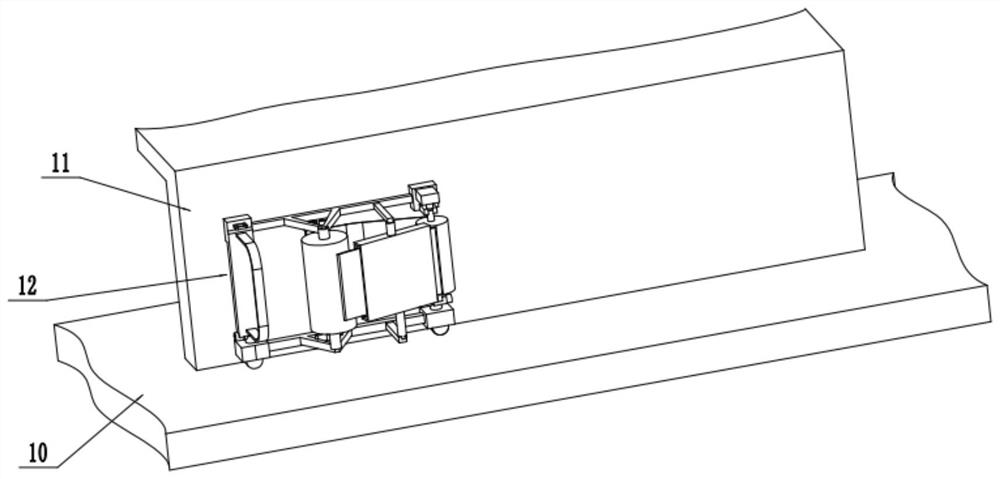

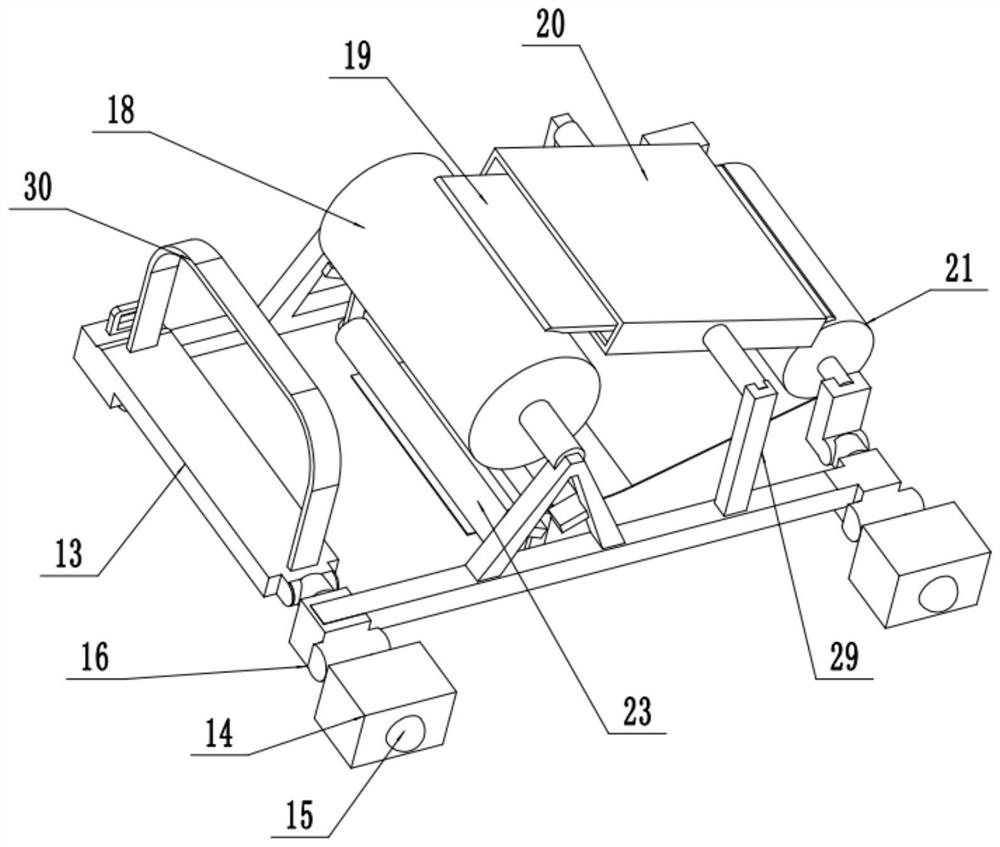

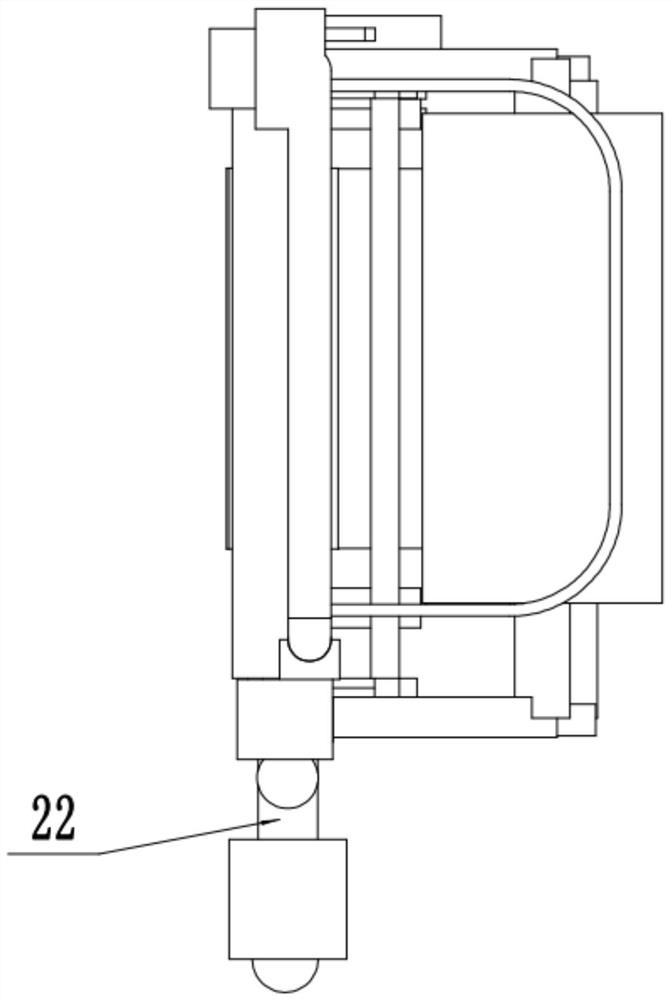

[0024] see Figure 1-5 , a basement waterproof coiled material laying device, comprising a laying device body 12, a waterproof coiled material roller 18, a waterproof coiled material 19, and a driving roller 21; The waterproof coiled material 19 is laid on the outer surface of the vertical outer wall 11 , so the frame 13 is vertically pasted on the outer surface of the outer wall 11 when the frame 13 is in use. The left and right sides of the bottom of the frame 13 in the vertical state are rotated downwards through the rotating shaft 16 and are connected with a vertical hydraulic rod 22. The bottom of the hydraulic rod 22 is fixedly equipped with a base 14 in a rectangular structure, and the lower side of the base 14 is connected by rolling. There is a bottom wheel 15, and the bottom of the frame 13 is rotationally connected with the hydraulic rod 22 through the rotating shaft 16, so as to facilitate the adjustment of the angle between the frame 13 and the base 14, and then w...

Embodiment 2

[0028]On the basis of Embodiment 1, a group of heating chambers 20 in a rectangular structure are arranged above the frame 13 between the waterproof roll 18 and the driving roller 21, and the upper and lower side walls of the heating chamber 20 are fixedly connected to the frame through pillars 29. On the front side wall of the middle part of 13, the waterproof coiled material 19 conveyed from the waterproof coiled material roller 18 to the driving roller 21 will pass through the inside of the heating chamber 20, and the upper and lower sides of the inner heating chamber 20 are symmetrically provided with air outlet holes 27, and the air outlet holes The top of 27 communicates with a hot air blower 28 fixed on the upper and lower inner tops of the heating chamber 20. Start the hot air blower 28 to generate hot air, and then send it to the waterproof membrane 19 passing through the heating chamber 20 through the air outlet 27, thereby heating the waterproof membrane 19 Make it s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com