Continuous heating and defrosting air source heat pump control method

A technology of air source heat pump and control method, which is applied in the direction of climate sustainability, refrigerators, refrigeration components, etc., and can solve problems that affect heat pump heat supply, oscillation, and delay in stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

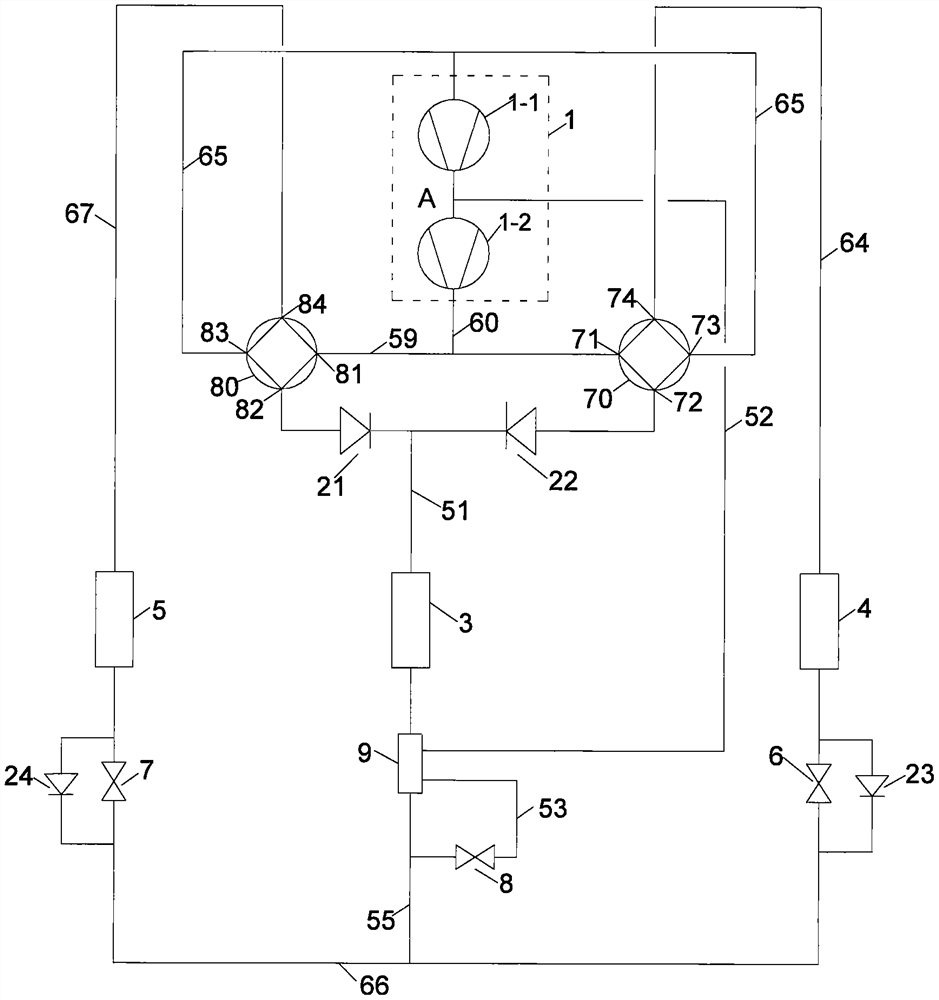

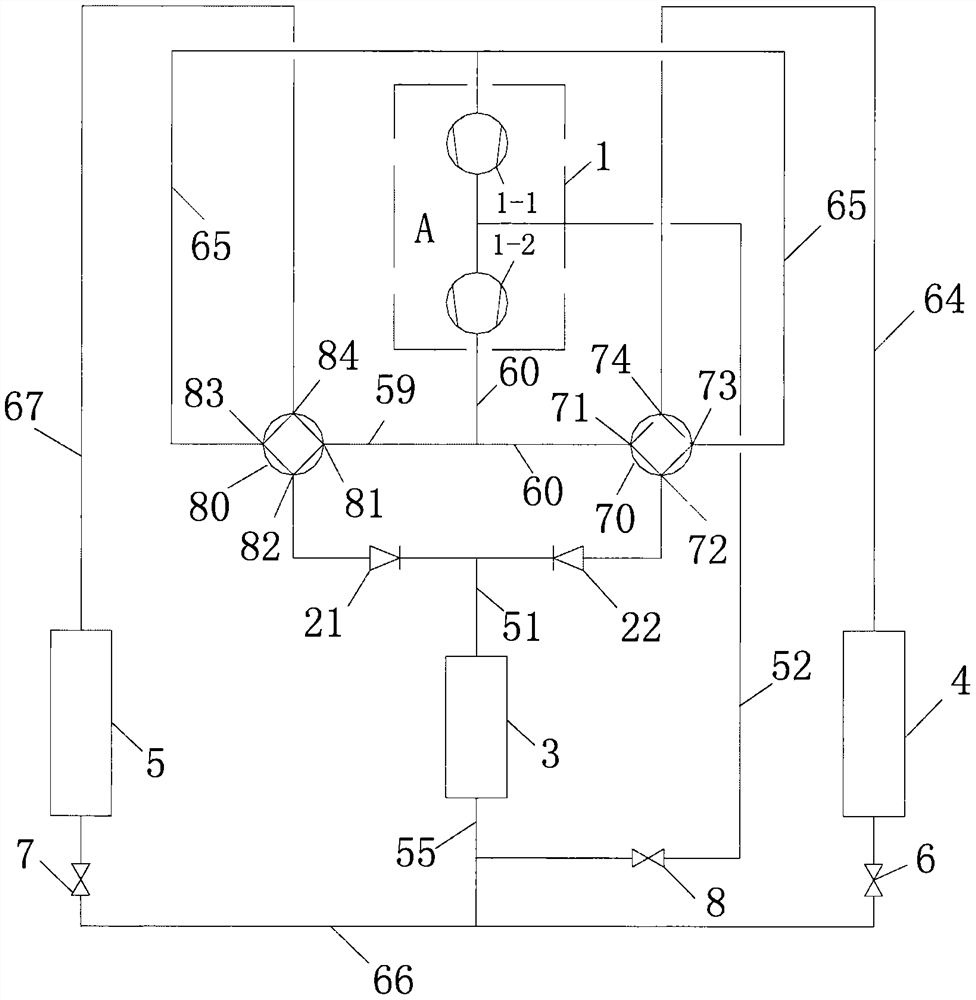

[0050] like figure 1 As shown, this embodiment is an application Figure 4 The shown patent is an air source heat pump capable of continuous heating and defrosting, which is used in occasions with heating needs. The whole device includes the following components: compression mechanism 1 (including low-pressure stage 1-1, high-pressure stage 1-2), four-way valve 70, four-way valve 80, main electronic expansion valve 6, main electronic expansion valve 7, outdoor replacement Heater 4, outdoor heat exchanger 5, heater 3; auxiliary electronic expansion valve 8, economizer 9.

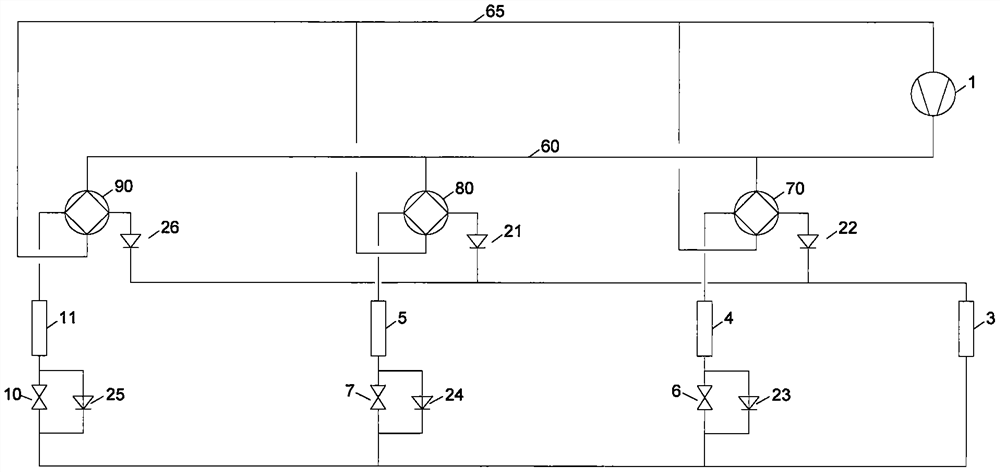

[0051] Auxiliary electronic expansion valve 8 and economizer 9 form a gas injection enthalpy increasing system, and compression mechanism 1 is a compressor capable of realizing gas injection enthalpy increasing. However, when the climate is not very cold, the auxiliary electronic expansion valve 8 and the gas injection enthalpy increasing system formed by the economizer 9 can be used; like image 3 shown....

Embodiment 2

[0105] For fixed frequency compressors, figure 1 In the program shown in the defrosting process, if the second defrosting method is adopted, that is: when any group of outdoor heat exchangers meets the defrosting conditions, they will enter the defrosting state and defrosting them, and the defrosting ends After that, continue to defrost another group of outdoor heat exchangers; when the two groups of outdoor heat exchangers have defrosted, the air source heat pump will enter the normal operation state again.

[0106] If during the normal operation of the air source heat pump, in the outdoor heat exchanger 4 and the outdoor heat exchanger 5, it is first detected that the outdoor heat exchanger 4 meets the defrosting conditions and needs to enter the defrosting state to defrost it; figure 1 The basic control requirements of the scheme shown in the second defrosting mode are as follows.

[0107] (1) During the normal operation of the air source heat pump, in the outdoor heat e...

Embodiment 3

[0135] For the inverter compressor, if during the normal operation of the air source heat pump, in the outdoor heat exchanger 4 and the outdoor heat exchanger 5, it is first detected that the outdoor heat exchanger 4 meets the defrosting condition and needs to enter the defrosting state When defrosting; figure 1 The basic control requirements of the scheme shown in the first defrosting mode are as follows.

[0136] (1) During the normal operation of the air source heat pump, in the outdoor heat exchanger 4 and the outdoor heat exchanger 5, when the outdoor heat exchanger 4 meets the defrosting conditions and needs to enter the defrosting state before defrosting, the compression Engine 1 is unloaded first; the controller records the opening values of main electronic expansion valves 6 and 7 before unloading at the same specified time before unloading of compressor 1; after unloading of compressor 1, it is stable after one continuous operation time period; when running in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com