Air-conditioner outdoor unit hood with defrosting structure

A technology for outdoor units and outdoor units of air conditioners, which is applied to air conditioning systems, refrigerators, household appliances, etc. It can solve the problems of affecting the heating effect and comfort, prolonging the defrosting time, and the condensed water is easy to freeze. Defrost time, improve defrost speed, good effect of dust prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

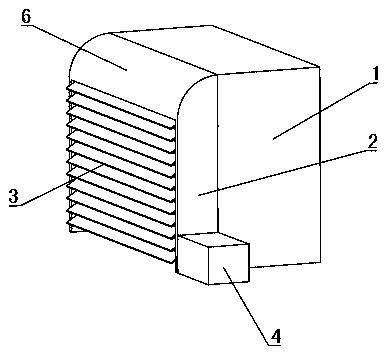

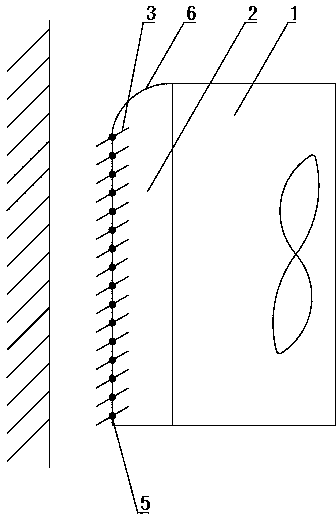

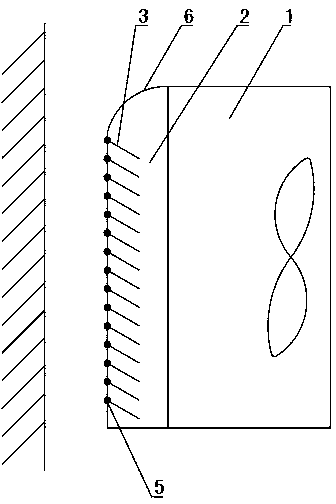

[0031] Figure 1~2 It is the best embodiment of the air conditioner outdoor machine cover with defrosting structure of the present invention, below in conjunction with the attached Figure 1~8 The present invention will be further described.

[0032] refer to Figure 1~2 , an air conditioner outdoor machine cover with a defrosting structure, including an outdoor unit 1, an upper windshield 6, a side windshield 2 and a shutter 3, and the upper windshield 6 and two side windshields 2 are fixed on the outside of the outdoor unit 1 One side of the heat exchanger is surrounded by a steady flow insulation chamber to prevent the hot air from escaping from the side of the heat exchanger. At the same time, the side windshield 2 can prevent the air from moving laterally and prevent the air flow from taking away the heat on the side of the heat exchanger. , the heat preservation effect is good, the louver 3 fixes the rear side of the steady flow heat preservation chamber, the louver 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com