Fastener feed head

一种紧固件、供给头的技术,应用在薄料处理、扳手、金属加工设备等方向,达到快循环速率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

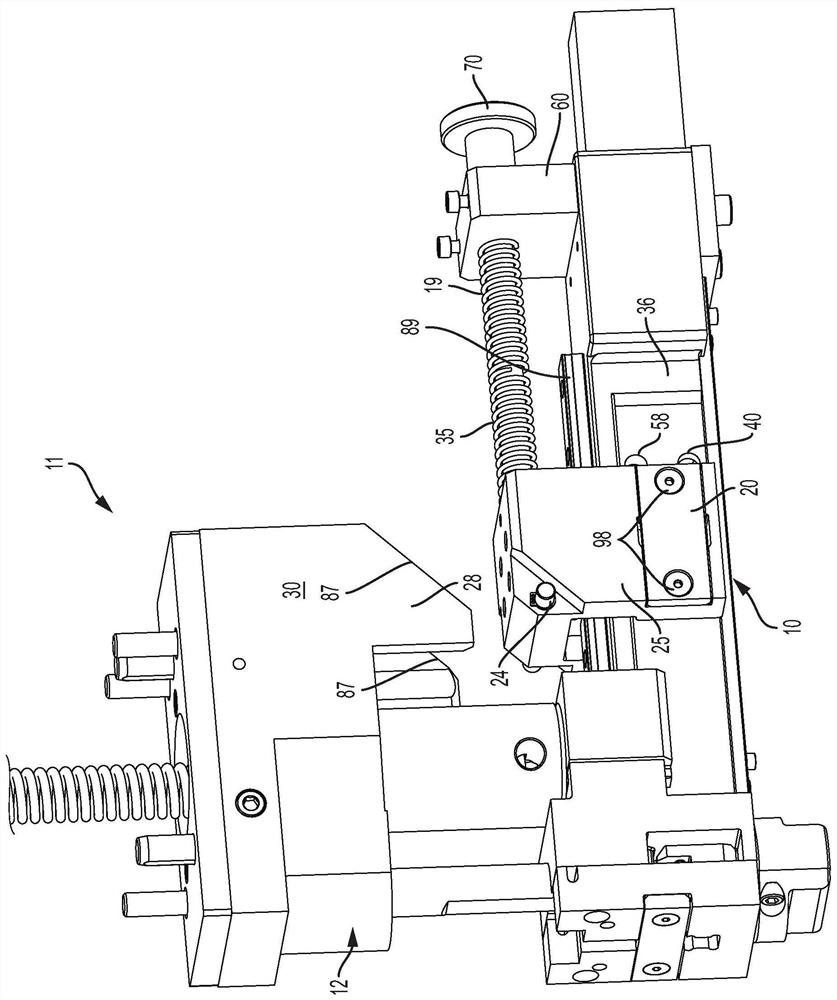

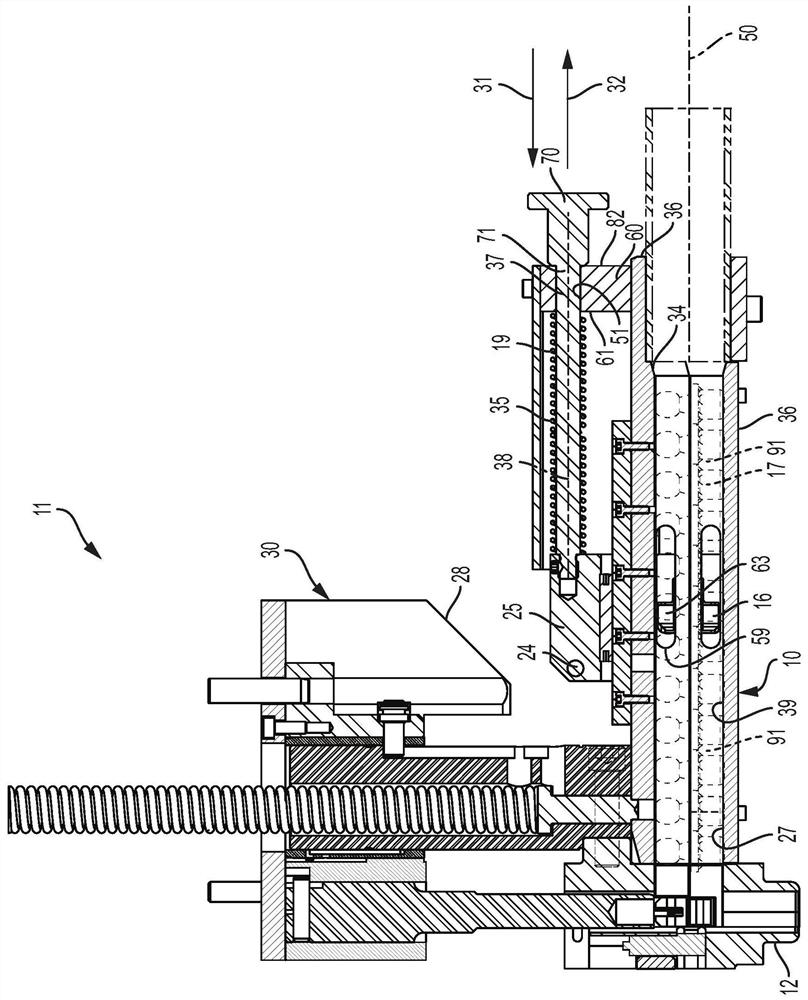

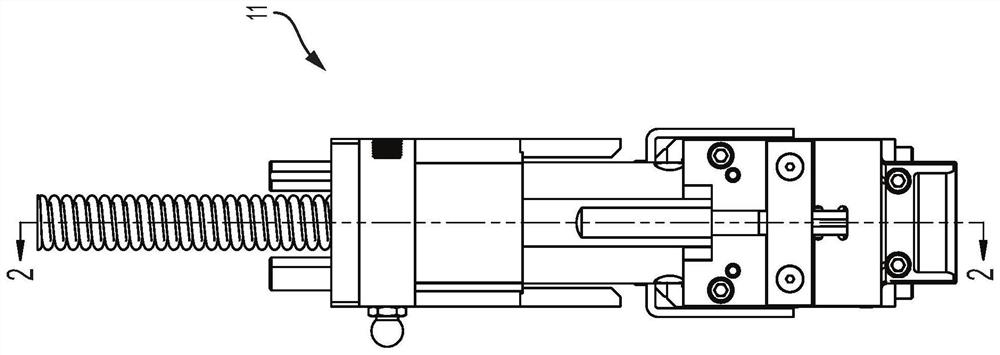

[0036] A fastener feeding head according to a preferred embodiment of the present invention is shown in the drawings and generally designated by the reference numeral 10 . In the embodiments illustrated herein and described below, the fastener feeding head 10 feeds fasteners 17 to the fastener installation head 12 of the fastener installation apparatus. refer to figure 1 , 2and 6 , the fastener feed head 10 includes a chute 36 having a feed passage 39 having an upstream region proximate to the chute inlet 34 , a downstream region proximate to the chute outlet 27 , and a feed axis 50 . The chute 36 may support and guide the fastener 17 from the chute inlet 34 to the chute outlet 27 coupled with the fastener installation head 12 . The fastener feeding head 10 may be used to feed any self-attaching fastener, including punched and set studs, bolts, ball studs, punched and set nuts, and other female fasteners of this type. exist figure 2 , Figure 8A , Figure 9 and Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com