A Method for Effectively Inhibiting the Precipitation of Second Phase in Ni-Mn-Sn-Fe Alloy

A technology of alloy and cylinder, which is applied in the field of Ni-Mn-Sn-Fe metal fiber preparation, can solve the problem of easy precipitation of the second phase, and achieve the effects of fast heat conduction, high solidification rate and fine grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

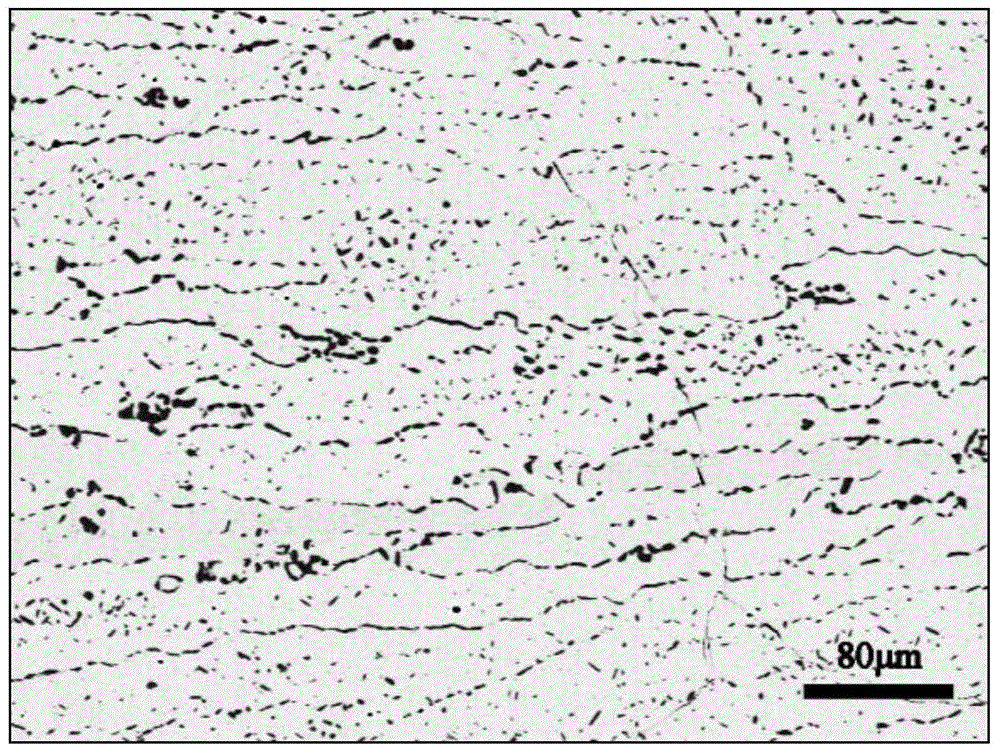

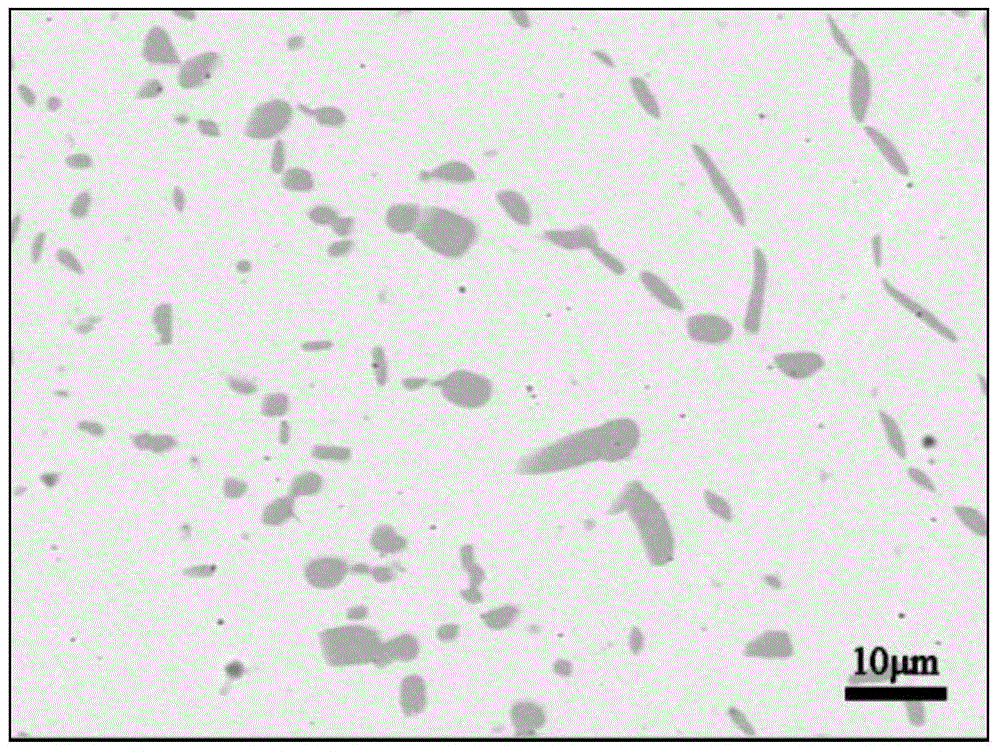

[0023] Specific Embodiment 1: The method for effectively suppressing the precipitation of the second phase of the Ni-Mn-Sn-Fe alloy in this embodiment is implemented according to the following steps:

[0024] 1. Seal the Ni-Mn-Sn-Fe alloy cylindrical ingot in a quartz glass tube, vacuumize it with a mechanical pump, keep it at a temperature of 900-950°C for 24-72 hours, and cool it to room temperature with the furnace to obtain the heat-treated For ingot casting, the heat-treated ingot is cut into multi-section small cylindrical ingots with a wire electric discharge machine. After the surface is polished and bright, it is put into water for ultrasonic cleaning, and dried to obtain the cleaned alloy cylindrical ingot;

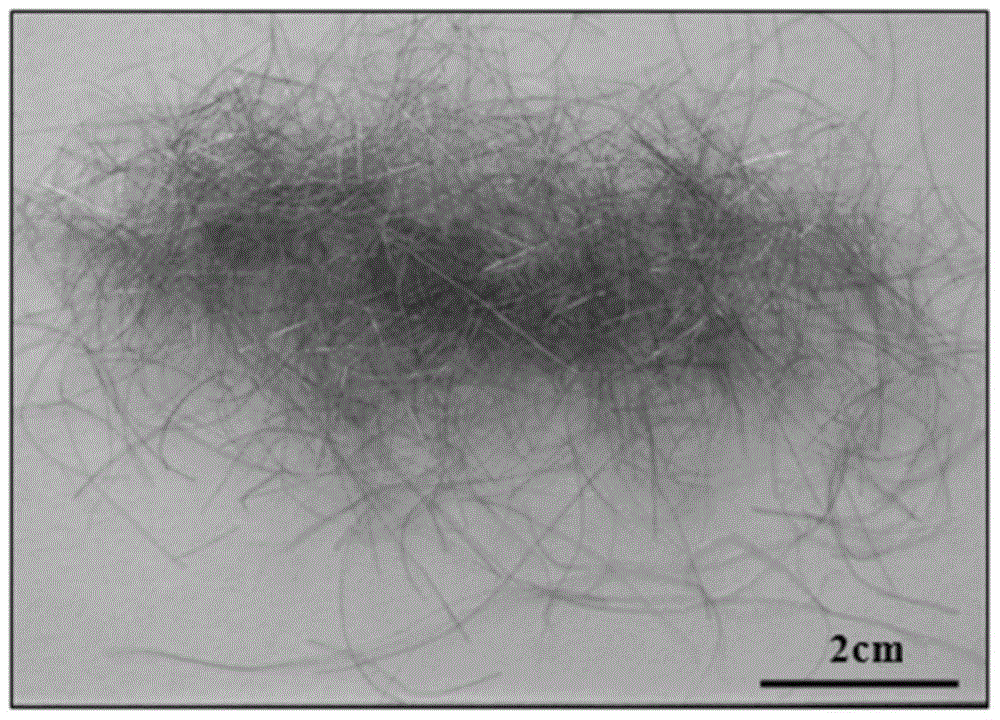

[0025] 2. Put the cleaned alloy cylindrical ingot into the alumina hollow cylinder, and then put it into the electromagnetic induction heating coil in the working room of the melt drawing equipment. The axis of the alumina hollow cylinder is perpendicular to the ...

specific Embodiment approach 2

[0031] Specific embodiment two: the difference between this embodiment and specific embodiment one is that step one uses a mechanical pump to evacuate until the air pressure is 10 -2 ~10 -3 Pa. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0032] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the height of the small cylindrical ingot in step 1 is 30-40 mm, and the diameter is 10-15 mm. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com