Gas-solid fluidized bed calcination reactor

A fluidized bed and reactor technology, applied in the field of gas-solid fluidized bed calcination reactors, can solve the problems of low reaction efficiency, ineffective use of reactor space, and insufficient utilization of heat, and achieves good mass transfer performance, The effect of high-efficiency thermal decomposition reaction of solid particles and uniform space-time distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

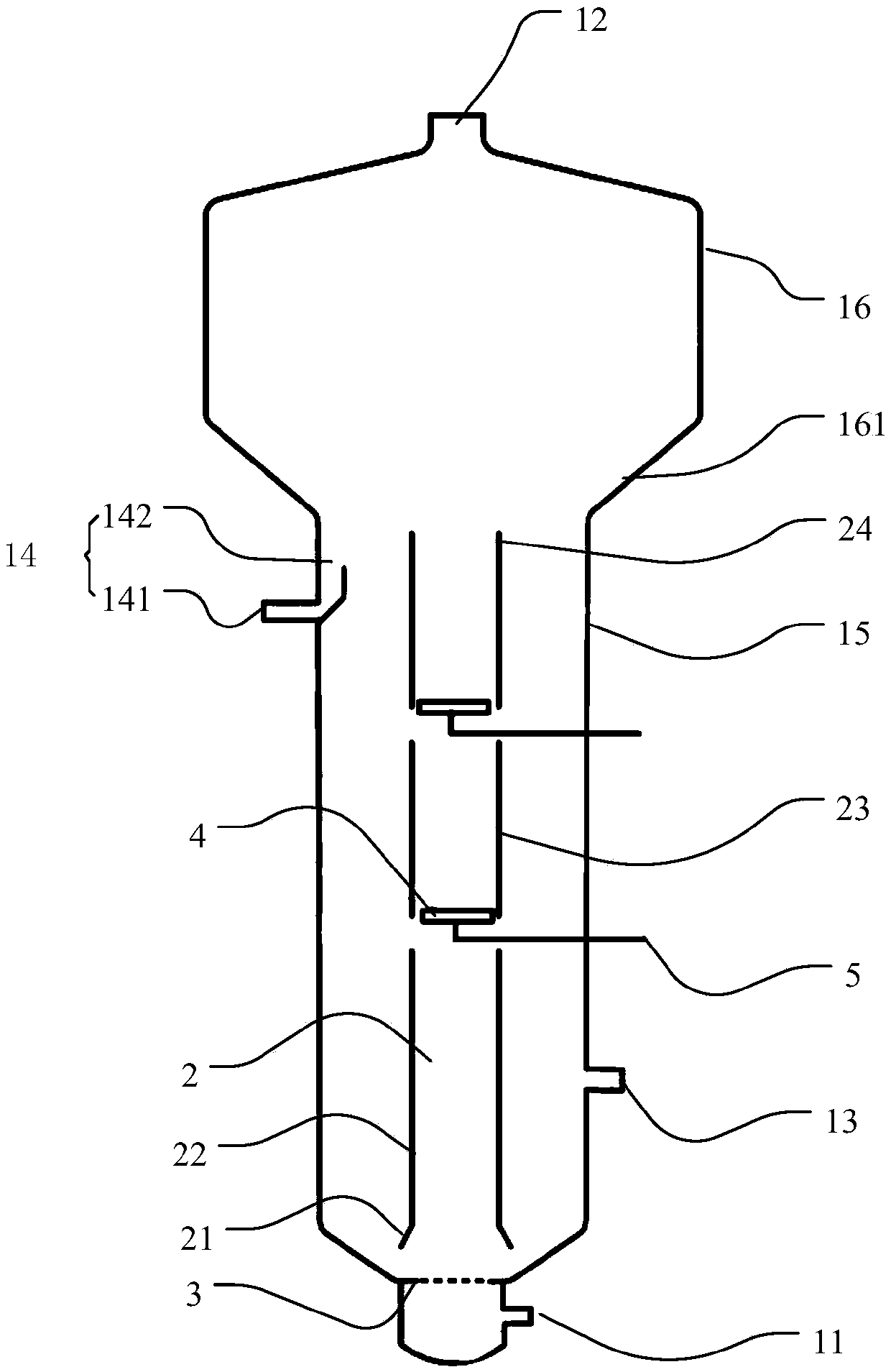

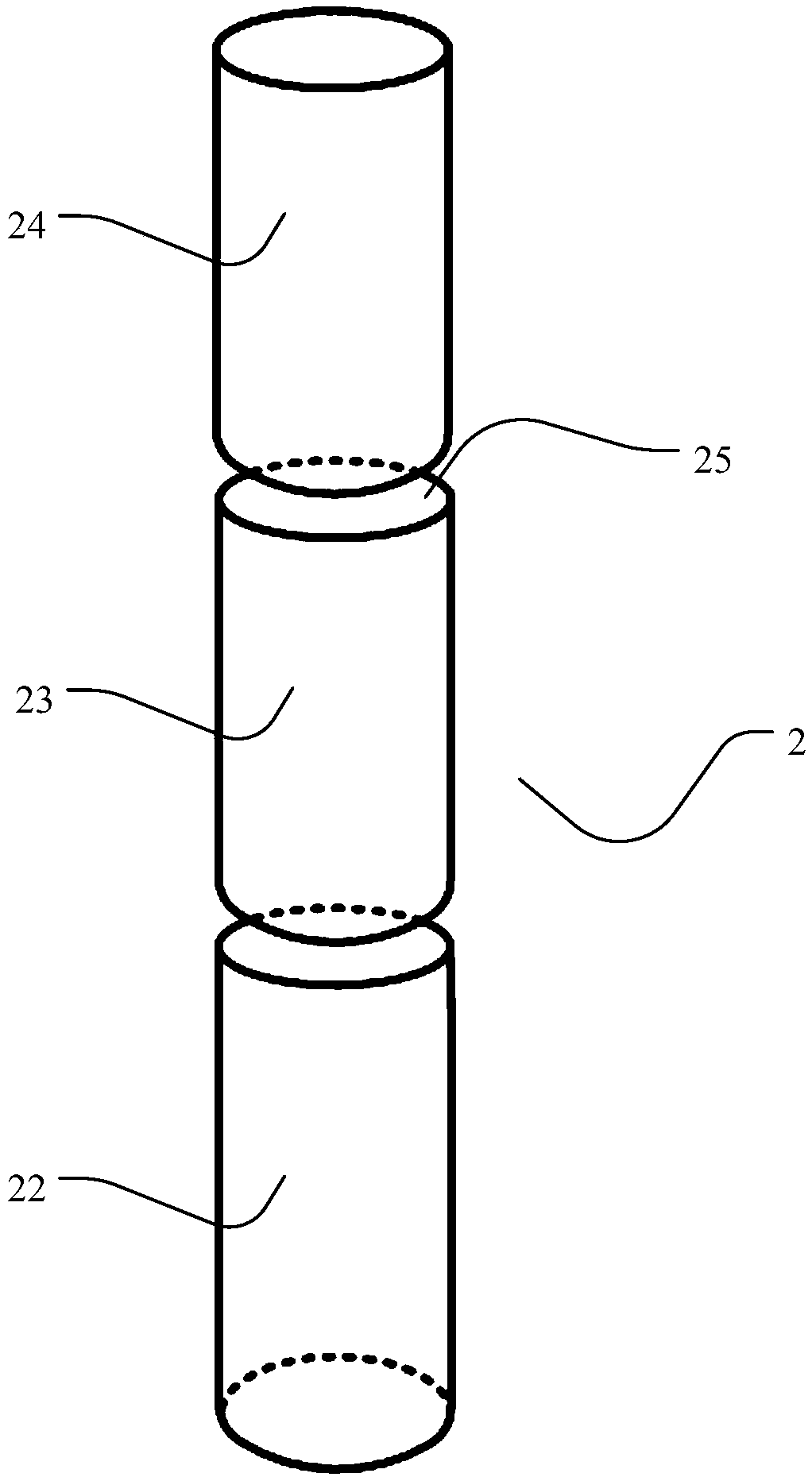

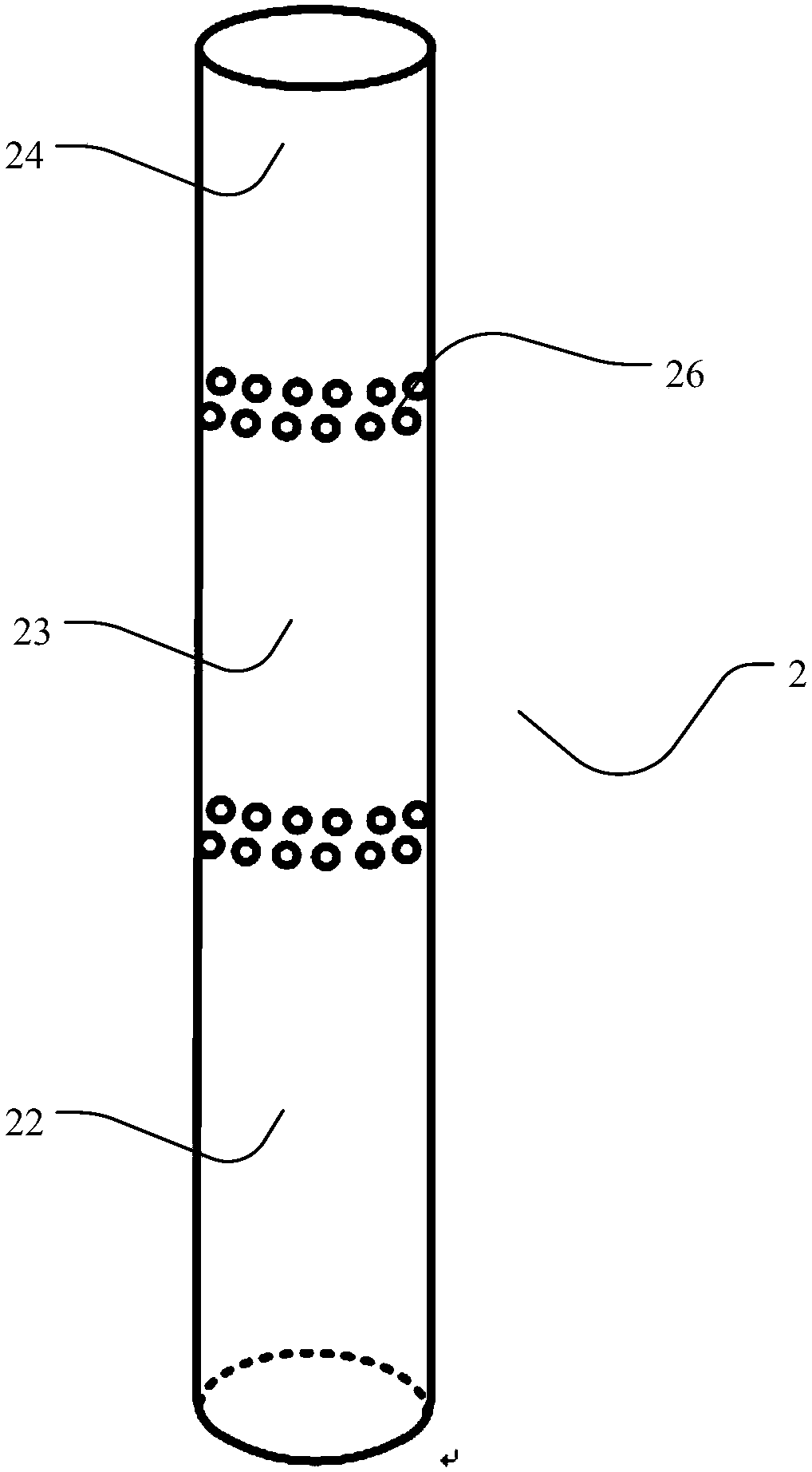

[0052] Embodiment 1: Two-stage internal circulation gas-solid fluidized bed calcining reactor

[0053] The specific structural parameters are as follows: in this embodiment, the guide tube 2 is divided into two guide sections, the reaction section 15 has an inner diameter of 125 mm and a height of 750 mm, and the separation section 16 has an inner diameter of 175 mm and a height of 250 mm; the guide tube 2 has a diameter of 62 mm and is divided into two sections , from top to bottom, the height of the first section is 350mm, and the height of the second section is 280mm. It adopts the method of multi-tube arrangement, the gap between the two tubes is 40mm, the diameter of the lower opening of the guide tube 2 is 80mm, and the taper is 1:2; Bottom 30mm. The main distributor 3 is a sieve disc distributor with a diameter of 80mm; the interstage distributor 4 is a ring distributor with a diameter of 40mm.

[0054] Taking calcium carbonate (average particle diameter 10 microns) as...

Embodiment 2

[0055] Embodiment 2: three sections internal circulating fluidized bed calcining reactor

[0056] The specific structural parameters are as follows: the reaction section 15 has an inner diameter of 125mm and a height of 950mm, the separation section 16 has an inner diameter of 175mm and a height of 220mm; the guide tube 2 has a diameter of 56mm and is divided into 3 sections, the first section is 320mm high, the second section is 280mm high, and the third section is high 260mm, take the way of opening between sections, the total area of openings between the two sections is 16cm2, and the total height occupied by the two sections of openings is 50mm; the diameter of the lower opening of the guide tube 2 is 80mm, and the taper is 1:2. The guide tube 2 is 30mm away from the bottom of the casing. The main distributor 3 is a sieve disc distributor with a diameter of 80mm; the interstage distributor 4 is a ring distributor with a diameter of 35mm.

[0057] Taking calcium carbonat...

Embodiment 3

[0058] Embodiment 3: calcining magnesium chloride monohydrate prepares basic magnesium chloride Mg(OH)Cl

[0059] Adopt the calcination reactor among the embodiment 1, high-temperature gas is hot air, and temperature is 340 ℃, MgCl2.H2O adopts MgCl2.6H2O prepares in advance (the mass fraction of water of crystallization is 19.2%), continuously adds reactor through high-level trough; Reaction The device is operated at normal pressure, and the total gas flow (standard condition) is 1800L / h, of which 70% of the gas is passed through the main distributor 3 at the bottom, and the rest is passed through an interstage distributor 4 . The average bed density in the reactor is 580kg / m3; the feed rate is 8kg / h. When the operation reaches a steady state, the average temperature of the first section of the reactor is 274° C., and the average temperature of the second section is 276° C.; the mass fraction of basic magnesium chloride in the obtained product is 78%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com