Dumpling wrapper pressing device

The technology of dumpling wrappers and pressing rings is applied in the field of pressing devices, which can solve the problem of only pressing a stack of dumpling wrappers, and achieve the effects of facilitating collection and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

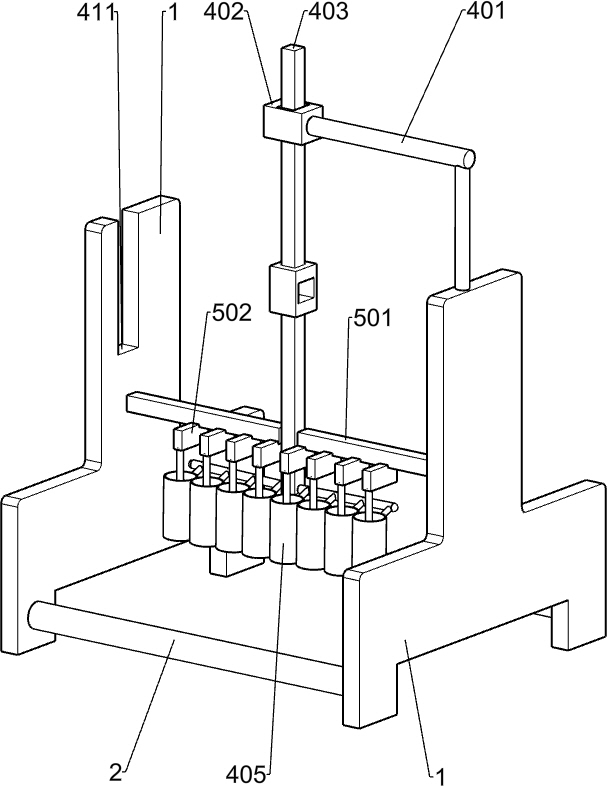

[0040] A dumpling skin pressing device, such as figure 1 As shown, it includes a bracket 1, a load-bearing rod 2, a moving mechanism 3, a forming mechanism 4 and a push-out mechanism 5. The load-bearing rod 2 is installed on both sides of the lower part of the bracket 1, the lower part of the bracket 1 is provided with a moving mechanism 3, and the top of the bracket 1 is on the right side. The upper part of the side and the left wall is connected with a forming mechanism 4, and the middle part of the bracket 1 is provided with a push-out mechanism 5.

[0041] When it is necessary to press the dumpling wrappers, stack multiple pieces of dough neatly on the parts of the moving mechanism 3, then start the parts of the forming mechanism 4, and the parts of the forming mechanism 4 will reciprocate up and down accordingly, when the parts of the forming mechanism 4 move down , the parts of the forming mechanism 4 press the dough to make dumpling wrappers. When the parts of the formi...

Embodiment 2

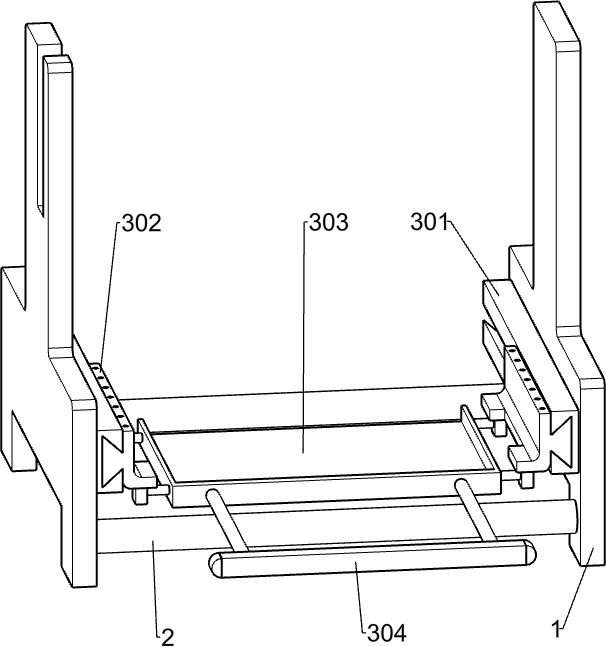

[0043] special reference Figure 1-5 As shown, the moving mechanism 3 includes a first slide rail 301, a first slide block 302, a placement frame 303 and a handle 304. The left and right sides of the lower part of the support 1 are equipped with a first slide rail 301, and the first slide rail 301 is provided with a slide type. There is a first slider 302, a placement frame 303 is connected between the first sliders 302 on both sides, and a handle 304 is arranged on the front side of the placement frame 303.

[0044] Stack the multi-layer skin neatly in the placement frame 303, then start the parts of the forming mechanism 4, the parts of the forming mechanism 4 move up and down, press the dumpling wrapper, and the parts of the pushing mechanism 5 push out the pressed dumpling wrapper, and the pressed dumpling wrapper After the skin falls on the placement frame 303, manually hold the handle 304, push the placement frame 303 backward, the first slider 302, the dumpling skin and...

Embodiment 3

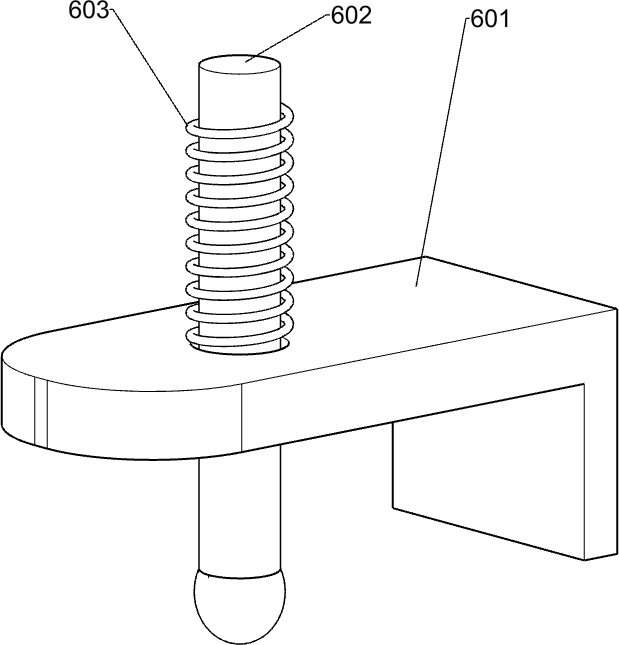

[0050] Specifically, such as Figure 6-10 As shown, a limit mechanism 6 is also included. The limit mechanism 6 includes a clamping plate 601, a clamping rod 602 and a first spring 603. The clamping plate 601 is installed in the center of the top of the first slide rail 301, and the clamping plate 601 is slidably provided with a clamping plate. Rod 602, a first spring 603 is connected between the upper part of the clamping rod 602 and the top of the clamping plate 601, the first spring 603 is wound on the clamping rod 602, a plurality of through holes 604 are evenly opened on the top of the first slider 302, and the clamping rod 602 is located within through hole 604 .

[0051] After the pressed dumpling wrappers fell into the collection frame, manually pull out the clamping rod 602 upwards, then push the placement frame 303 backwards, when the second through hole 604 on the placement frame 303 was positioned directly below the clamping rod 602 , manually stop pushing the pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com