Physical gear acquisition system and acquisition method for pure electric light commercial vehicle

A collection system, a pure electric technology, applied to vehicle components, circuits or fluid pipelines, transportation and packaging, etc., can solve problems such as the inability to guarantee the normal driving of vehicles, and achieve increased hardware costs, improved reliability, and simple circuit principles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

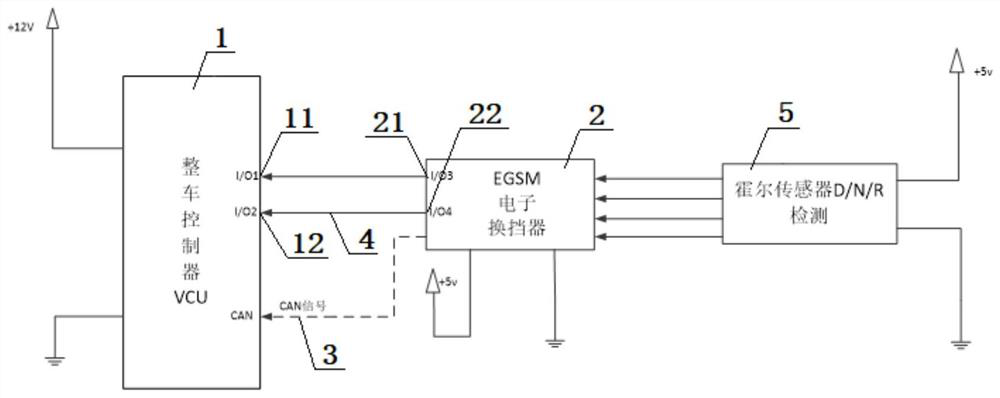

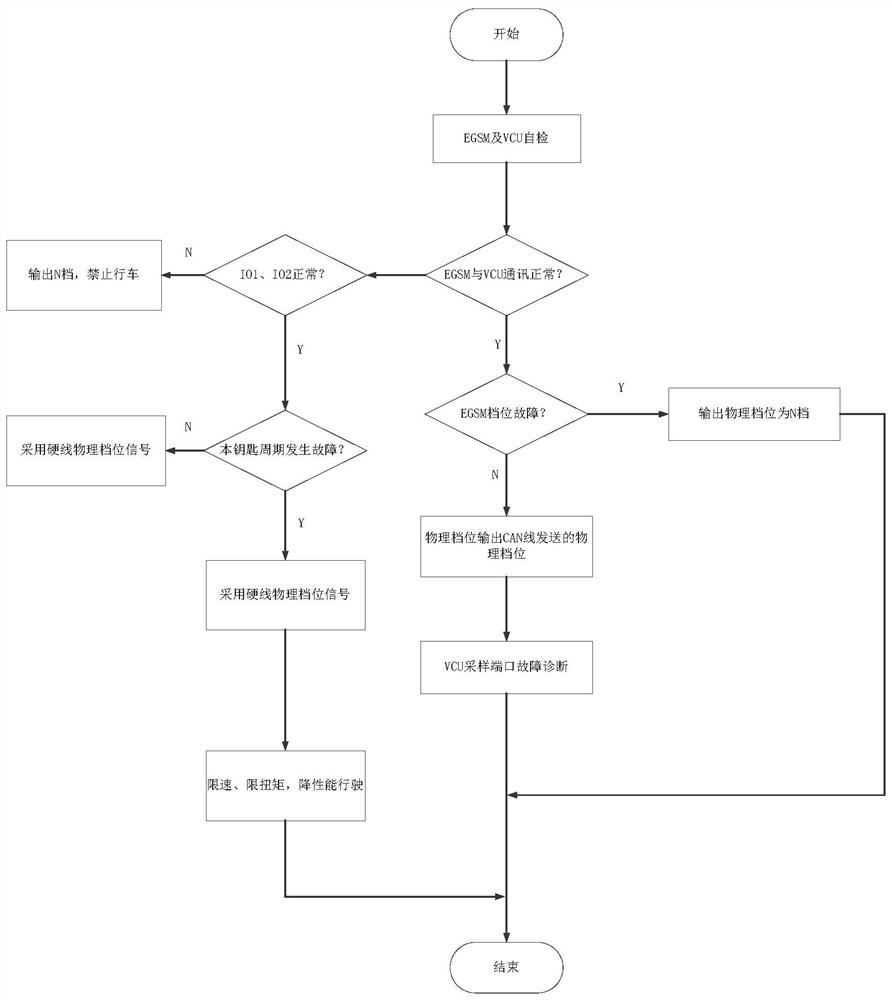

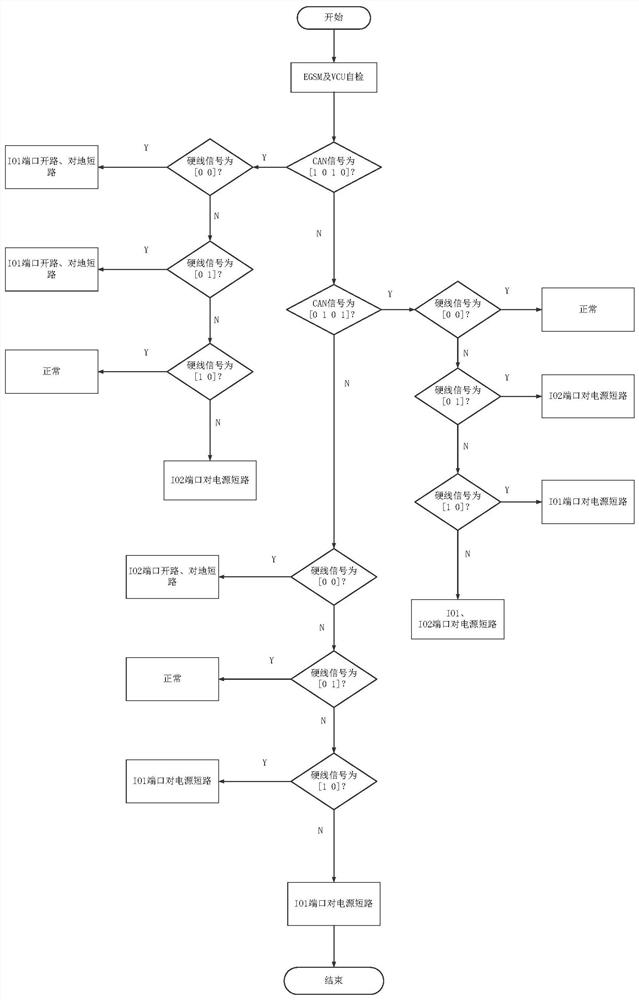

[0049] see Figure 1-Figure 4 , a pure electric light commercial vehicle physical gear acquisition system, comprising a vehicle controller 1, an electronic shifter 2, the vehicle controller 1 is connected to the electronic shifter 2 through a CAN bus 3; The vehicle controller 1 is provided with a No. 1 I / O input port 11 and a No. 2 I / O input port 12, and the electronic shifter 2 is provided with a No. 1 I / O output port 21 and a No. 2 I / O output port 22 , the No. 1 I / O output port 21 is connected to the No. 1 I / O input port 11, the No. 2 I / O output port 22 is connected to the No. 2 I / O input port 12 through hard wire 4, and the electronic shifter The signal input port of 2 is connected to the analog voltage output module 5 of the Hall sensor, and the analog voltage output module 5 of the Hall sensor is used to convert the rotation angle and displacement signal of the electronic shifter knob switch into an analog voltage signal and then transmit it For the electronic shifter 2,...

Embodiment 2

[0061] The difference with Example 1 is:

[0062] The method also includes the step of the electronic shifter 2 judging the real-time physical gear position according to four groups of analog voltage signals from the analog voltage output module 5 of the Hall sensor, the step is:

[0063] The electronic shifter 2 generates a logic level combination according to the analog voltage signal. If the generated logic level combination is [01 1 0], it is determined that the real-time physical gear is the D gear; if it is [0 1 0 1], Then it is judged that the real-time physical gear is the N gear; if it is [1 01 0], then it is judged that the real-time physical gear is the R gear; It is: if a certain group of analog voltage signals received is greater than or equal to K1*battery voltage V, and lasts for X1ms, a high level 1 is generated; if a certain group of analog voltage signals received is less than or equal to K2*battery voltage V, and lasts for X2ms , then a low level 0 is gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com