Lock of speed reduction device with clutch mechanism

A technology of clutch mechanism and deceleration device, which is applied to non-mechanical transmission-operated locks, building locks, building structures, etc., can solve the problems of small output torque, potential safety hazards, and large energy consumption, and achieve high power transmission efficiency and power consumption. The conduction direction is consistent and the effect of meeting practical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

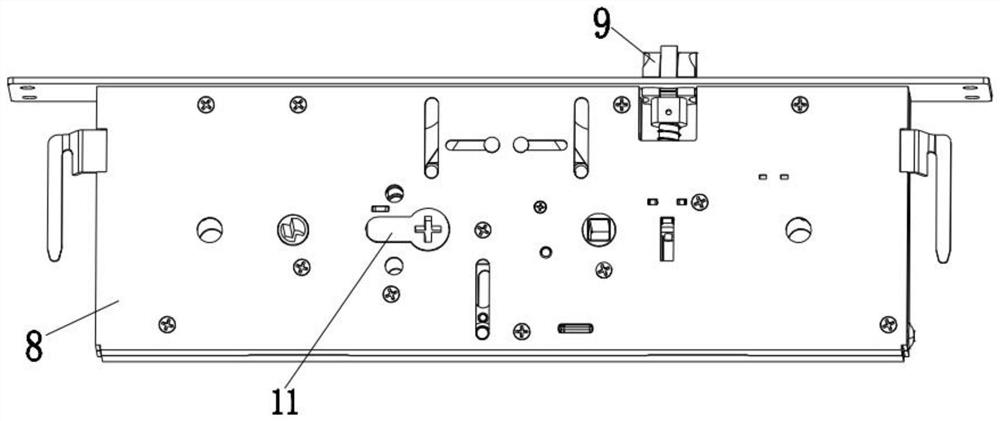

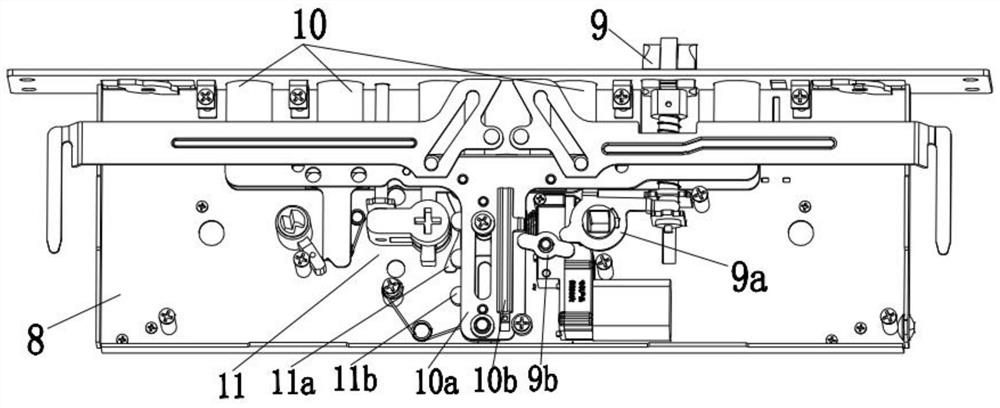

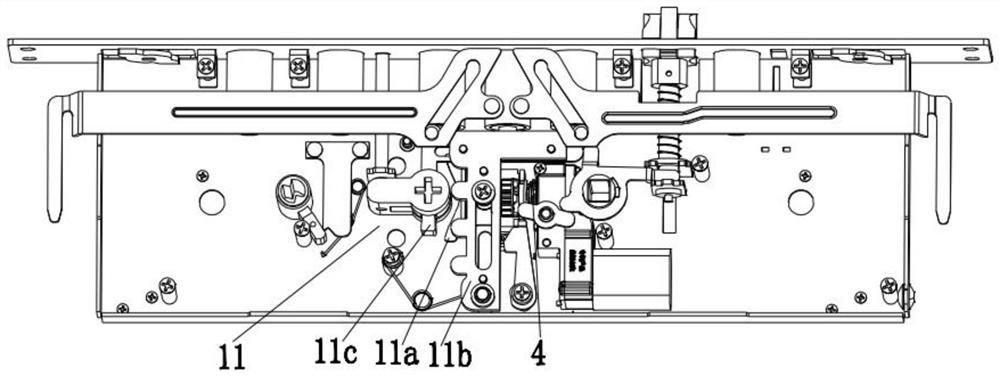

[0032] Such as Figure 1-8 As shown, a lockset with a deceleration device with a clutch mechanism includes a lock body 8, a main dead bolt 9, an auxiliary dead bolt 10, a key drive mechanism 11 and a deceleration device with a clutch mechanism, the main dead bolt 9, the auxiliary lock Tongue 10, key drive mechanism 11 and deceleration device with clutch mechanism are all arranged on the lock body 8;

[0033] The reduction device with a clutch mechanism includes a reduction box 5, a reduction gear set 6, a driving motor 7 and a clutch mechanism. box 5, and the output end of the drive motor 7 is connected to the clutch mechanism through the reduction gear set 6;

[0034] The auxiliary bolt 10 and the key driving mechanism 11 are drivingly connected to the clutch mechanism, and the auxiliary bolt 10 is drivingly connected to the main bolt 9 .

[0035] Preferably, the clutch mechanism includes a clutch shaft 1, an output gear 2, a clutch ring 3 and a clutch spring 4;

[0036] D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com