Plasma sewage purification device

A plasma and sewage purification technology, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, water pollutants, etc. It can eliminate the problems of lowering, poor removal of ammonia nitrogen and total nitrogen, etc., to achieve the effect of eliminating black and odorous water bodies, low operating costs, and easy automatic control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

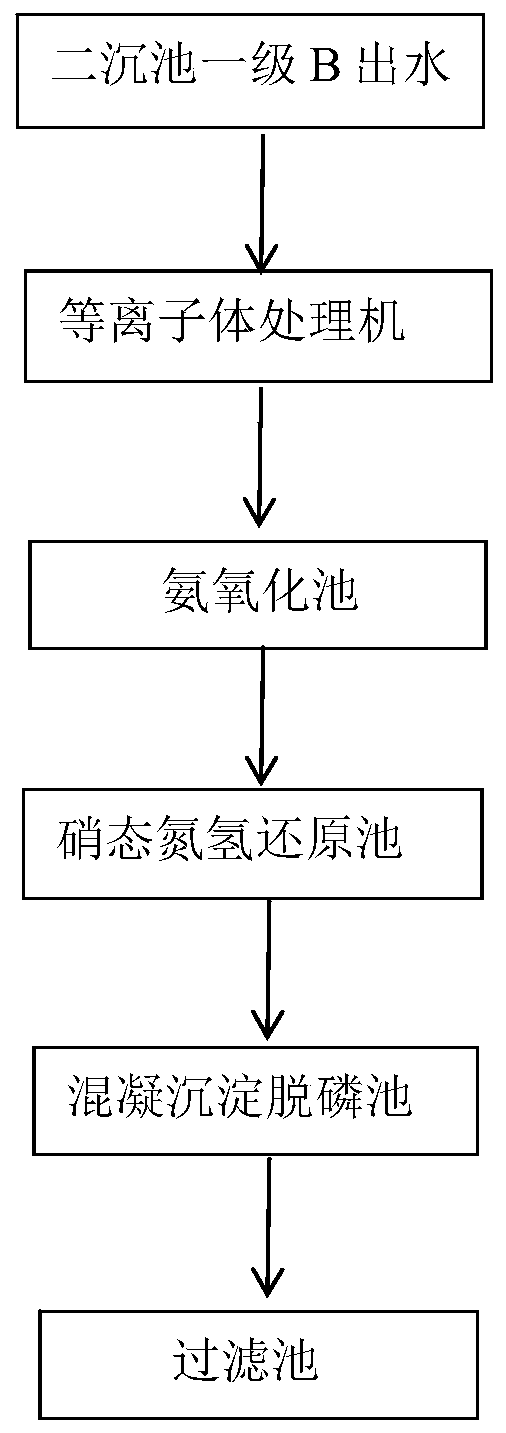

[0054] refer to figure 1 , a transformation example of a sewage treatment plant that has reached the first-level B discharge standard. After the secondary settling tank of the original project, a lift pump, plasma machine, oxidation pool, reduction pool and coagulation sedimentation tank are added; plasma machine, oxidation pool, The structure of the restore pool is as follows Figure 4 As shown, the discharge water of level B of the sewage plant is connected to the inlet of the plasma machine, the outlet water of the plasma machine is connected to the water inlet of the oxidation pool, the water outlet of the oxidation pool is the water inlet of the hydrogen reduction pool, and the outlet of the hydrogen reduction pool is The water inlet is connected with the coagulation sedimentation tank; a hydrogen supply pipe is also installed at the water inlet of the hydrogen reduction tank.

[0055] Table 4 shows the effluent water quality indicators of the sewage treatment plant of t...

Embodiment 3

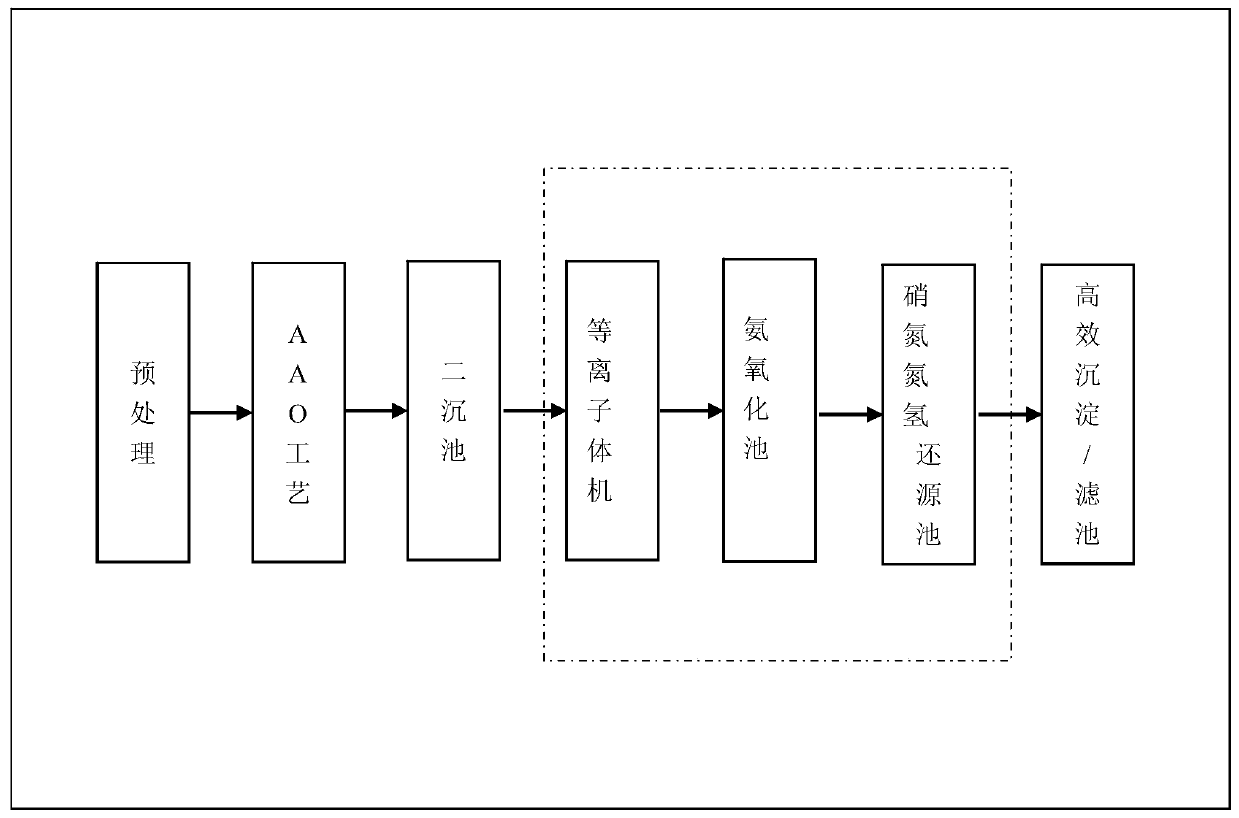

[0063] refer to figure 2 , a transformation example of a certain level A sewage treatment plant in the south, a plasma machine, an ammonia oxidation pool and a hydrogen reduction pool are added between the secondary sedimentation tank and the coagulation sedimentation tank of the original facility of the sewage treatment plant, ( figure 2 dotted line). The structure of plasma machine, oxidation pool and reduction pool is as follows: Figure 4 As shown, the discharge water of level A of the sewage plant is connected to the inlet of the plasma machine, the outlet water of the plasma machine is connected to the water inlet of the oxidation tank, the water outlet of the oxidation tank is the water inlet of the hydrogen reduction tank, and the outlet of the hydrogen reduction tank is The water inlet is connected with the coagulation sedimentation tank; a hydrogen supply pipe is also installed at the water inlet of the hydrogen reduction tank.

[0064] The effluent water qualit...

Embodiment 4

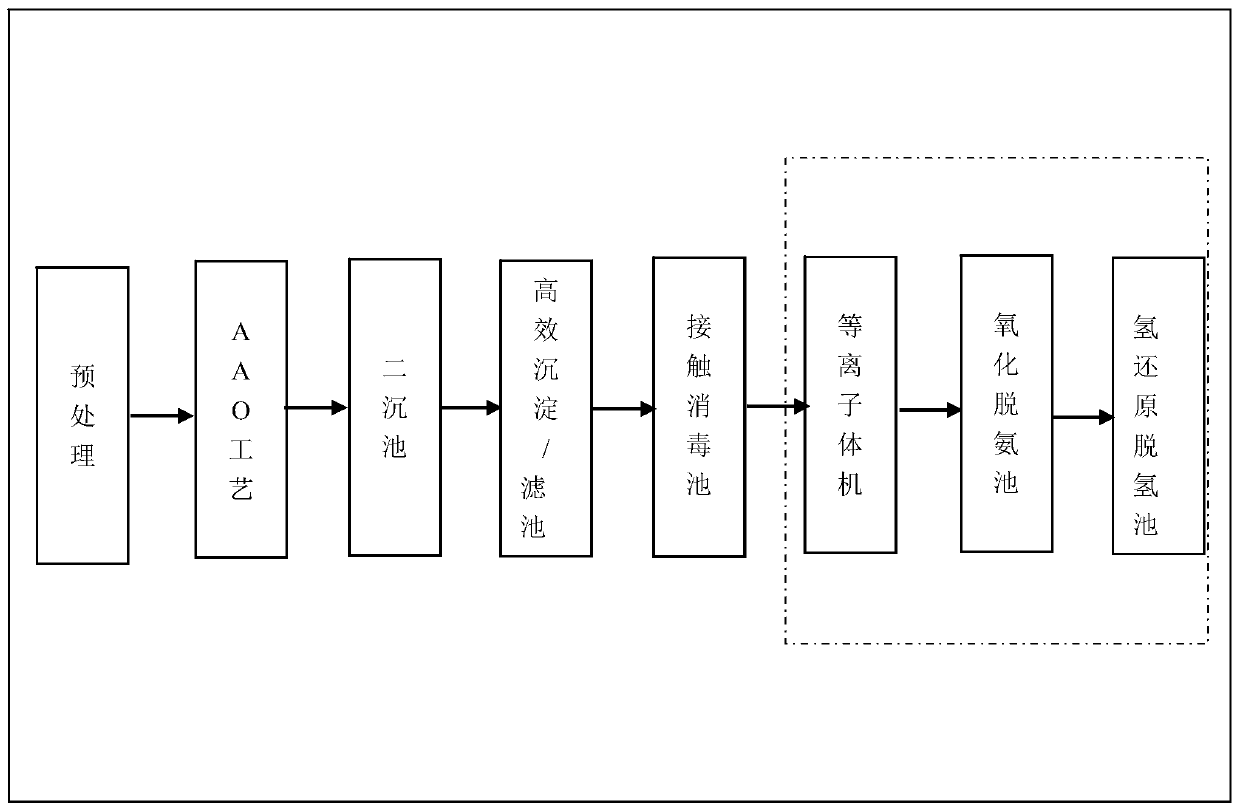

[0074] refer to image 3 , a transformation example of a sewage treatment plant with a certain level A discharge standard in the north. Due to the low temperature in winter in the north and the temperature of sewage water at 12-15°C, the removal effect of ammonia nitrogen and total nitrogen is poor, so it is located in the original facility ( image 3 ) After the contact disinfection pool, add plasma machine, ammonia oxidation pool and hydrogen reduction pool ( image 3 dotted line). The structure of plasma machine, oxidation pool and reduction pool is as follows: Figure 4 As shown, the discharge water of level A of the sewage plant is connected to the inlet of the electrolysis machine, the outlet water of the electrolysis machine is connected to the water inlet of the oxidation tank, the water outlet of the oxidation tank is the water inlet of the hydrogen reduction tank, and the water outlet of the hydrogen reduction tank is connected to the The coagulation sedimentation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com