Fuel mixing device of scramjet engine

A scramjet and engine technology, applied in rocket engine devices, machines/engines, jet propulsion devices, etc., can solve problems such as inability to promote fuel mixing, and achieve the effect of enhancing fuel mixing efficiency and promoting efficient mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

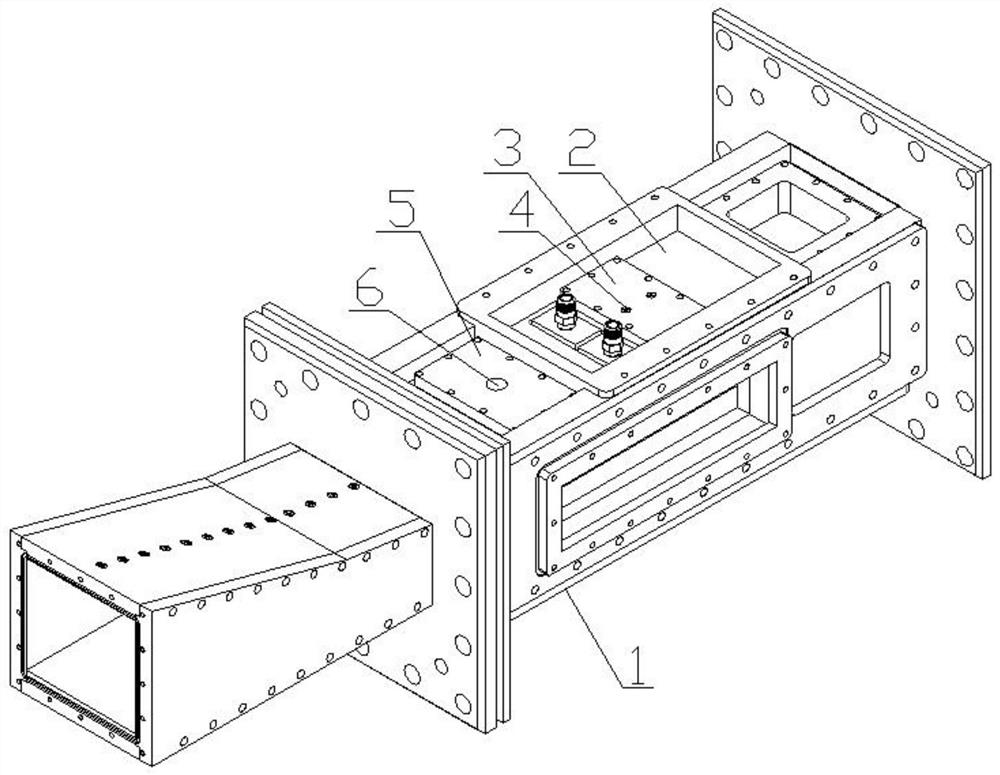

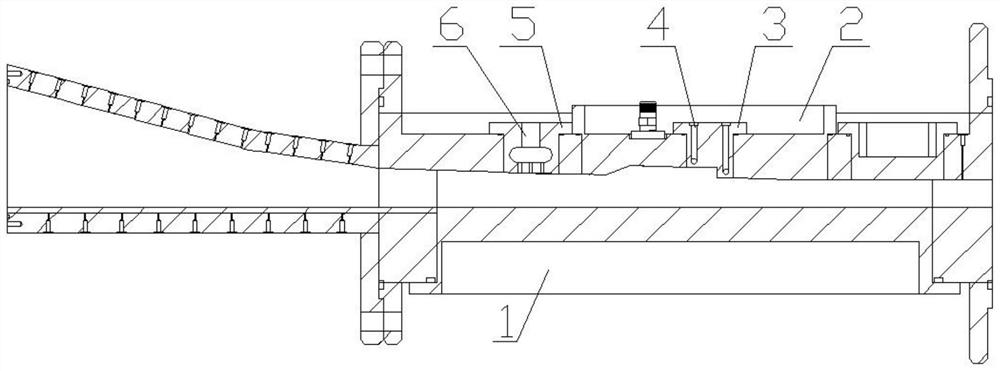

[0021] as attached figure 1 with figure 2 Shown: a kind of fuel blending device of scramjet engine, comprises engine body 1 and the groove 2 that is positioned at the middle part of engine body 1, and the total length of engine body 1 is 1700mm, and the inlet of air is opened on the left side of engine body 1, The inlet is a rectangular opening with a length of 100mm and a width of 50mm. The engine body 1 is bolted with a fuel injection block 3 fitted in the middle of the groove 2, and the fuel injection block 3 is provided with two spaced circular The first injection hole 4, the engine body 1 is also bolted with a jet air injection block 5 fitted on the left side of the groove 2, and the distance between the jet air injection block 5 and the groove 2 is 1 / 2 of the length of the engine. 5%-20%, the jet air injection block 5 is about 845mm away from the inlet of the engine body 1 .

[0022] An "O" type seal ring is installed between the jet air injection block 5 and the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com