Magnetostrictive TORQUE DETECTION SENSOR

A magnetostrictive, torque detection technology, used in torque measurement, instruments, measuring devices, etc., can solve the problem of reduced detection sensitivity, achieve uniform detection sensitivity, achieve miniaturization, and improve detection sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

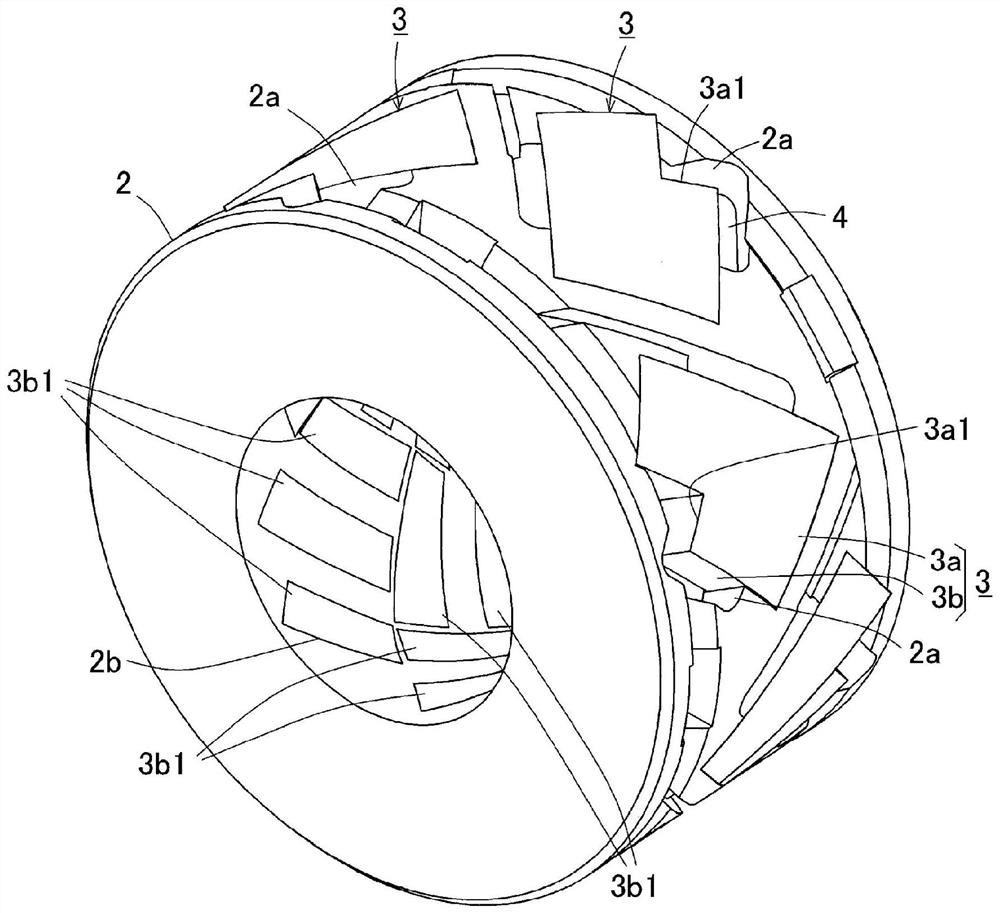

[0036] Hereinafter, an embodiment of the magnetostrictive torque detection sensor of the present invention will be described with reference to the drawings. First, refer to Figure 1 to Figure 7 , the schematic structure of the magnetostrictive torque detection sensor will be described.

[0037] As an example of the object S to be detected, it is desirable to use a material having a large inverse magnetostrictive effect. For example, materials having a large inverse magnetostrictive effect include FeCoV (Permender alloy), Fe-Al (aluminum-iron alloy), Fe-Nix (Permalloy), and spherical graphite cast iron (JIS: FCD70). In addition, the inverse magnetostrictive effect is a phenomenon in which magnetic properties change when stress is applied to the magnet from the outside. In addition, if the subject S is subjected to magnetic annealing in advance as necessary, the torque acting on the subject S can be appropriately detected as will be described in detail later. In addition, ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com