Intelligent anti-tearing conveying belt system

A conveyor belt and anti-tear technology, which is applied to conveyors, conveyor objects, conveyor control devices, etc., can solve problems such as conveyor belt tearing, and achieve the effect of improving early warning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

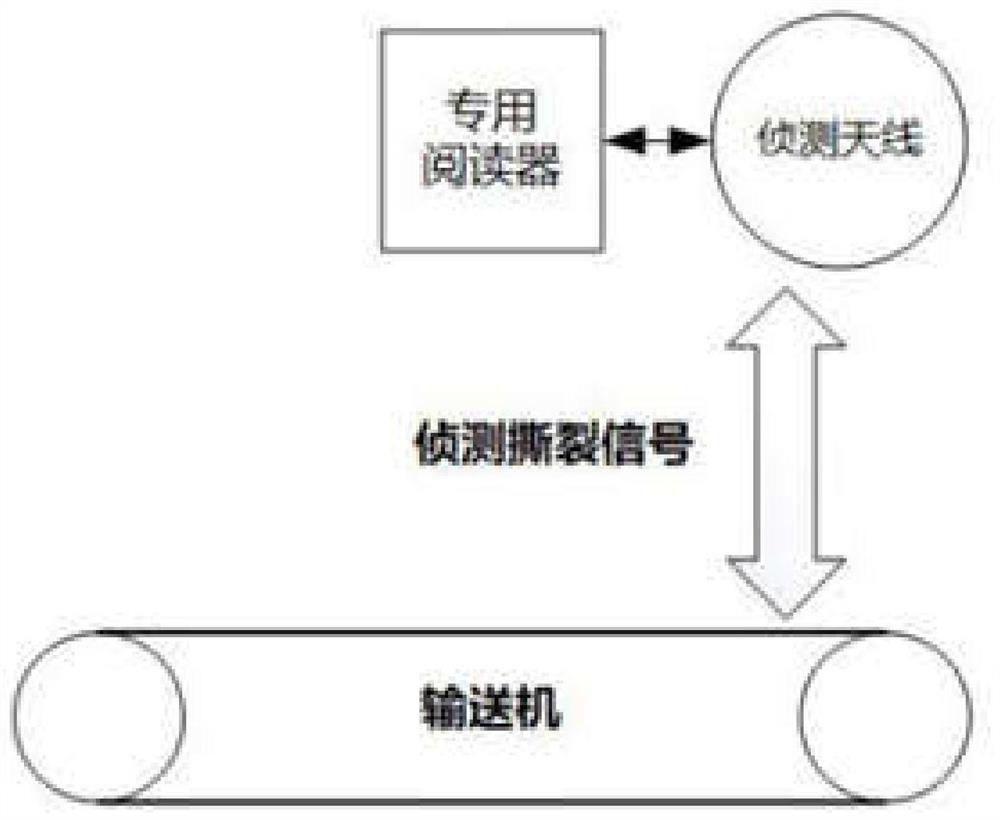

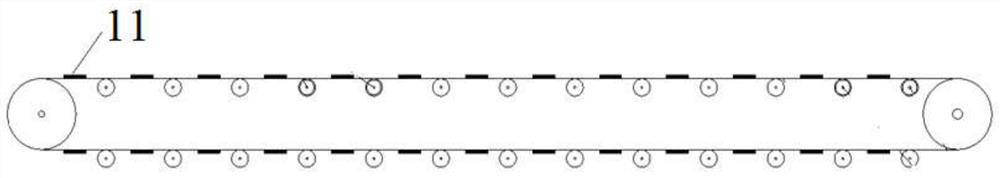

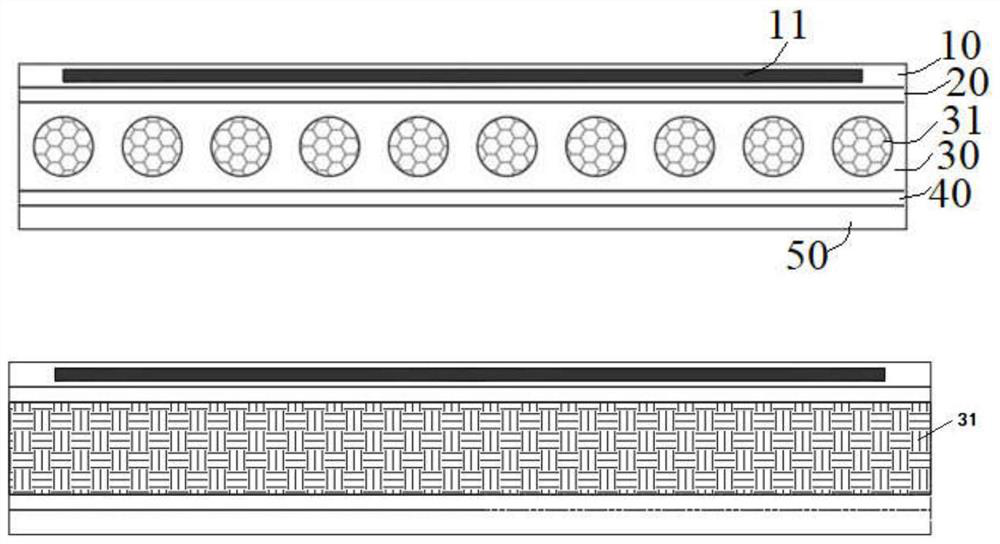

[0036] Refer to attached figure 1 - attached Figure 8 , an intelligent anti-tear conveyor belt system in this embodiment, including a conveyor belt and a reader 500 arranged on one side of the conveyor belt, the body of the conveyor belt is provided with a tear-proof label 11, and the reader 500 is equipped with a There is a power supply circuit 510 electrically connected to each other, a core processing module 520 and a radio frequency processing module 530, the radio frequency processing module 530 is electrically connected to the antenna interface 540 on the reader 500, and the anti-tear label 11 and the reader 500 Connect via RF signal. When the conveyor belt is torn, the signal triggered by the anti-tear label embedded in the conveyor belt can send the conveyor belt tear fault signal to the reader 500 in real time, and the reader 500 can identify the received signal And timely early warning, early warning efficiency is greatly improved.

[0037] The intelligent RFID a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com