Automatic material taking device and method arranged on cyclone dust collector

A technology of automatic material retrieving and cyclone dust collection, which is applied in the direction of sampling devices, chemical instruments and methods, cleaning methods and utensils, etc., can solve problems such as misoperation, slow efficiency, and health damage to staff, so as to reduce physical damage, Improve production efficiency and realize the effect of automatic material retrieving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

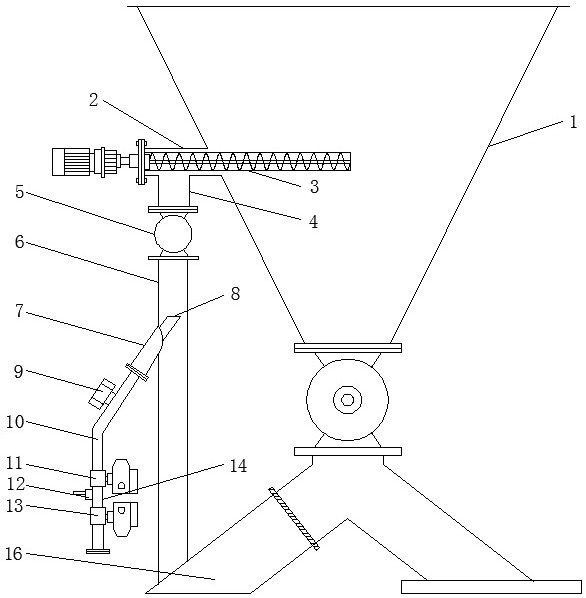

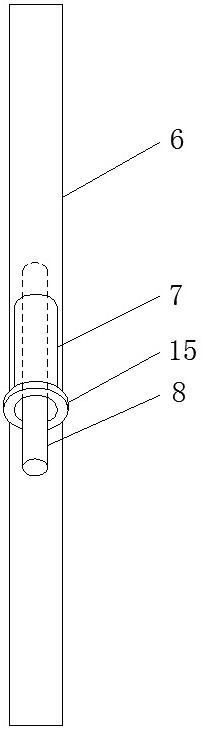

[0025] Such as Figure 1-2 As shown, an automatic reclaiming device provided by a cyclone dust collector, it includes a powder collecting silo 1, the side of the powder collecting silo 1 is provided with a side retrieving cylinder 2, and the side retrieving cylinder 2 A screw feeder 3 is arranged inside, and the screw feeder 3 is fixedly connected with the side feeding barrel 2 by means of welding flanges. A discharge closing air valve 5 is arranged below the discharge opening 4, and the bottom of the discharge closing air valve 5 is also connected with a bypass blanking pipe 6, and the side of the bypass blanking pipe 6 is provided with a mounting flange The pipeline 7, the inside of the installation flange pipeline 7 is provided with a feed orifice plate 8, the feed orifice plate 8 is fixedly connected with the installation flange pipeline 7 through a flange plate 15, and the feed orifice plate 8 is also provided with There is a vibration motor 9, and the vibration motor 9 ...

Embodiment 2

[0029] The present invention comprises the following steps when in use:

[0030] Step 1): The screw feeder pulls out the powder that falls into the powder collection bin, and sends the powder to the bypass blanking pipeline through the discharge closing air valve, and the powder in the bypass blanking pipeline is due to its own Flying down due to gravity and negative pressure inside the pipeline;

[0031] Step 2): Feed the orifice to meet the powder and bring the powder into the sample tube;

[0032] Step 3): Turn on the vibration motor to bring the sample material into the fixed volume material tube without residue. At this time, open the upper electric ball valve and close the lower electric ball valve. After the sampling of the fixed volume material tube is completed, open the lower electric ball valve and close the upper electric ball valve. capacity sampling;

[0033] Step 4): When the discharge of the sample material in the constant volume material tube is completed, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com