Warehouse material storage management device

A technology for managing devices and materials, applied in the field of warehouse management, can solve the problems of ineffective materials, time-consuming and laborious, storage, etc., and achieve the effect of enhancing the sealing effect and avoiding cluttered placement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

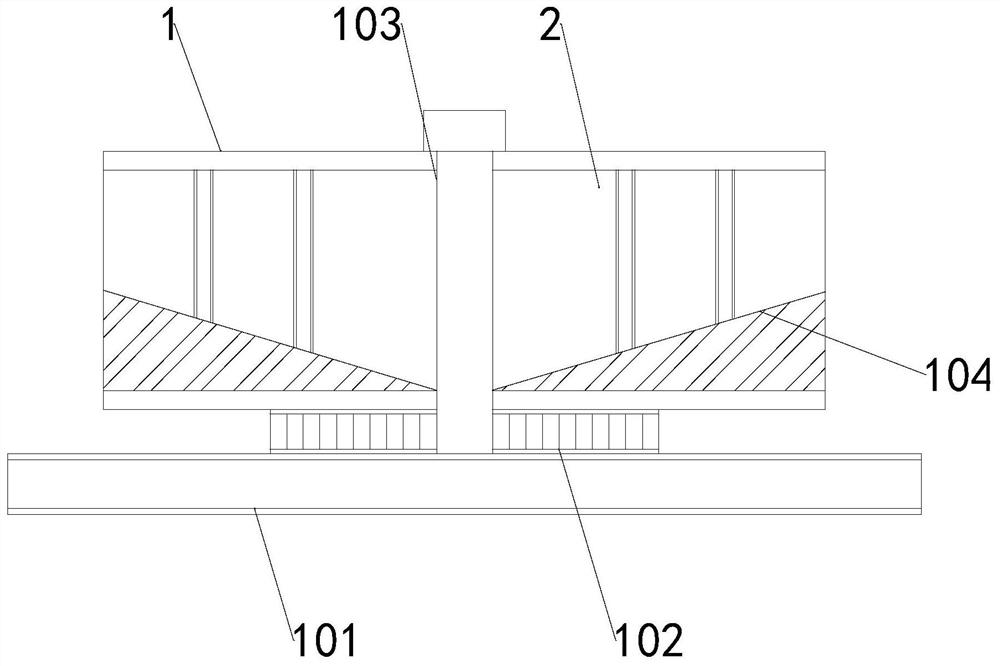

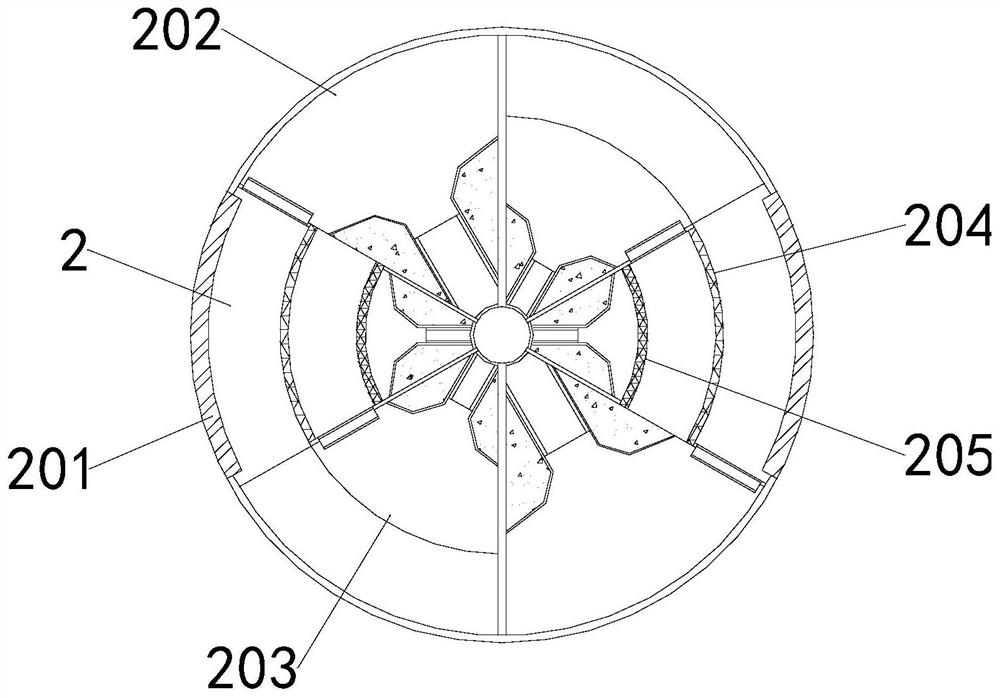

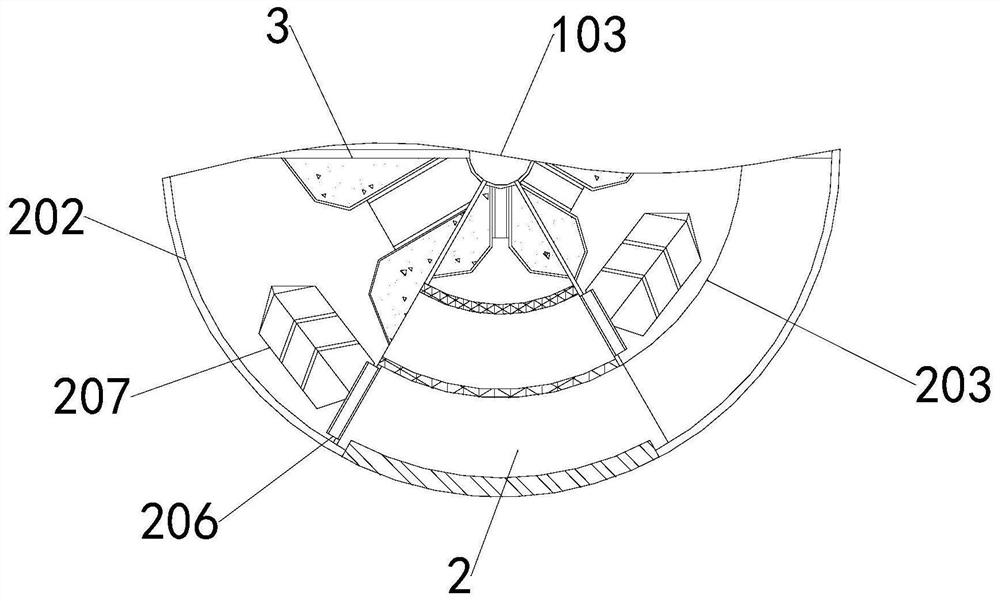

[0027] See Figure 1 to 9 In the embodiment of the present invention, a warehouse material warehousing management device includes: a device main body 1, a screen material cavity 2, a first material distribution cavity 202, a second material distribution cavity 203, a limit plate 3 and a blocking member 304. The device main body 1 is provided with a distributing component, and the two ends of the device main body 1 are respectively provided with a sieve cavity 2; the inside of the distributing component is provided with a limiting component, and the device main body 1 is cylindrical, and the bottom of the device main body 1 A base 101 is provided, and the limiting plate 3 is respectively arranged at both ends of the inner inner end of the screen material cavity 2, the first material dividing cavity 202 and the second material dividing cavity 203, and the blocking member 304 is movably connected to the limiting plate 3 Internal upper end.

[0028] Preferably, a turntable 102 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com