Automotive lock structure, automotive door lock and automobile

A technology of car locks and deadbolts, applied in the field of locks, can solve the problems of complex transmission mechanism of locks, unfavorable manufacturing cost of locks, large overall volume of locks, etc., and achieve the effect of simplified transmission mechanism, fewer internal transmission mechanisms, and good locking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

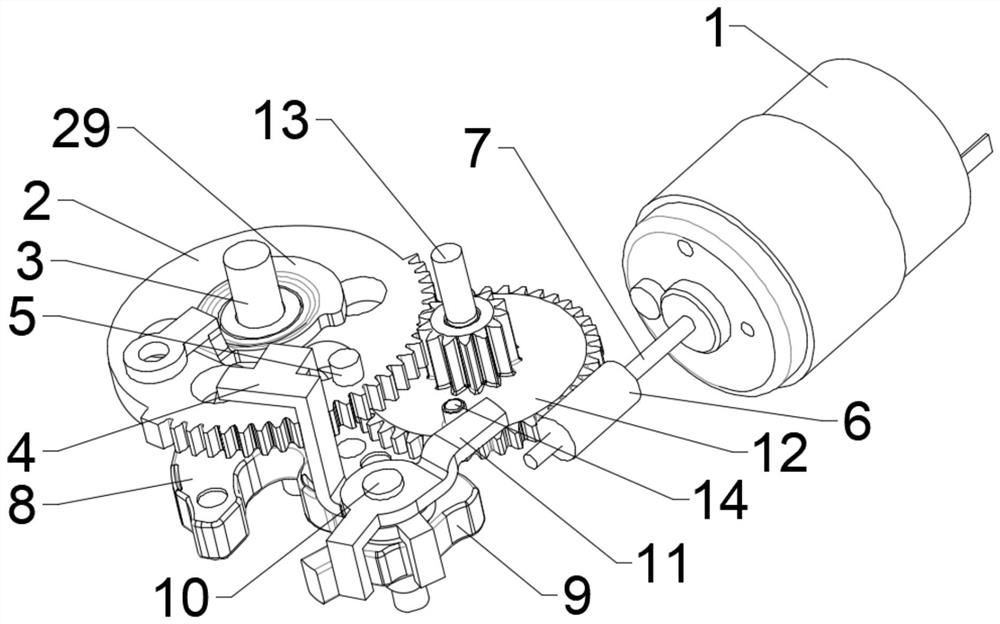

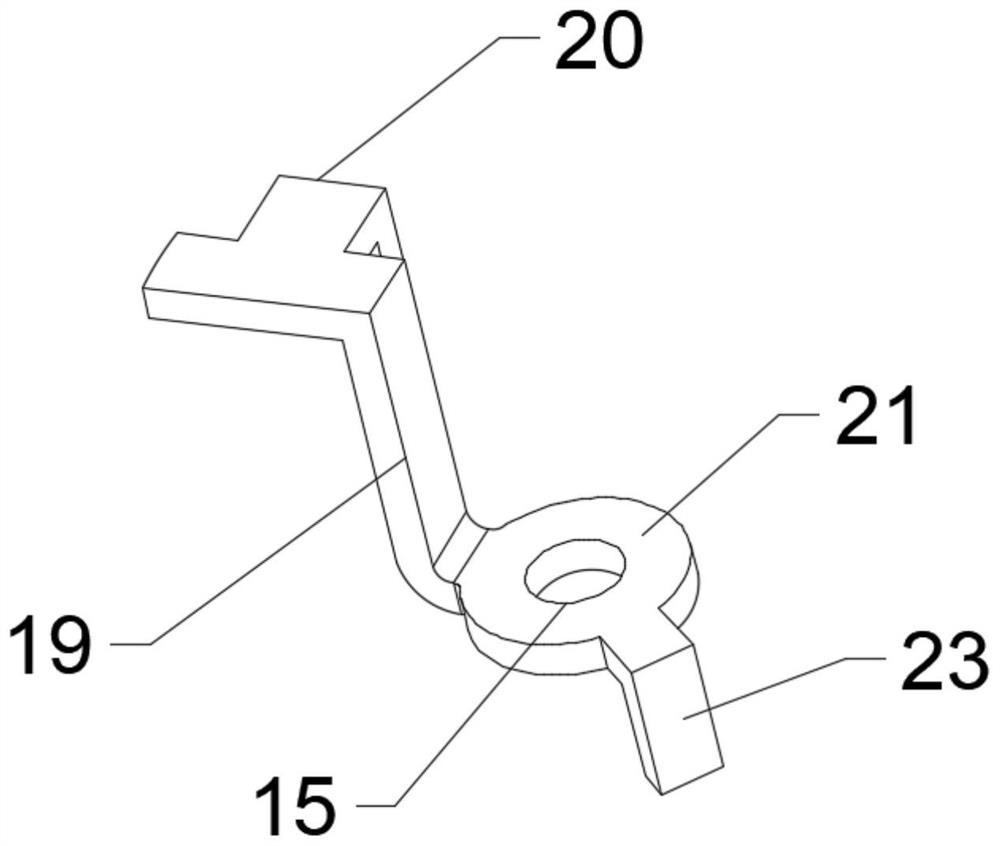

[0049] Such as Figure 1-5 As shown, the present embodiment provides a car lock structure, including: a driving member 1, a rotating member 2, a lock tongue 8 for clamping a lock cylinder, a braking member 9 for locking the lock tongue 8, and a driving member 9 for driving The brake part 9 is unlocked with the unlocking part 29 of the lock tongue 8 and the linkage part 4 is used to contact and cooperate with the unlocking part 29 to realize unlocking.

[0050] The driving part 1 is connected with the rotating part 2 in transmission, and the rotating part 2 is driven to rotate by the driving part 1. The driving part 1 drives the dead bolt 8 to rotate through the rotating part 2 and cooperates with the braking part 9 to realize the locking of the locking cylinder.

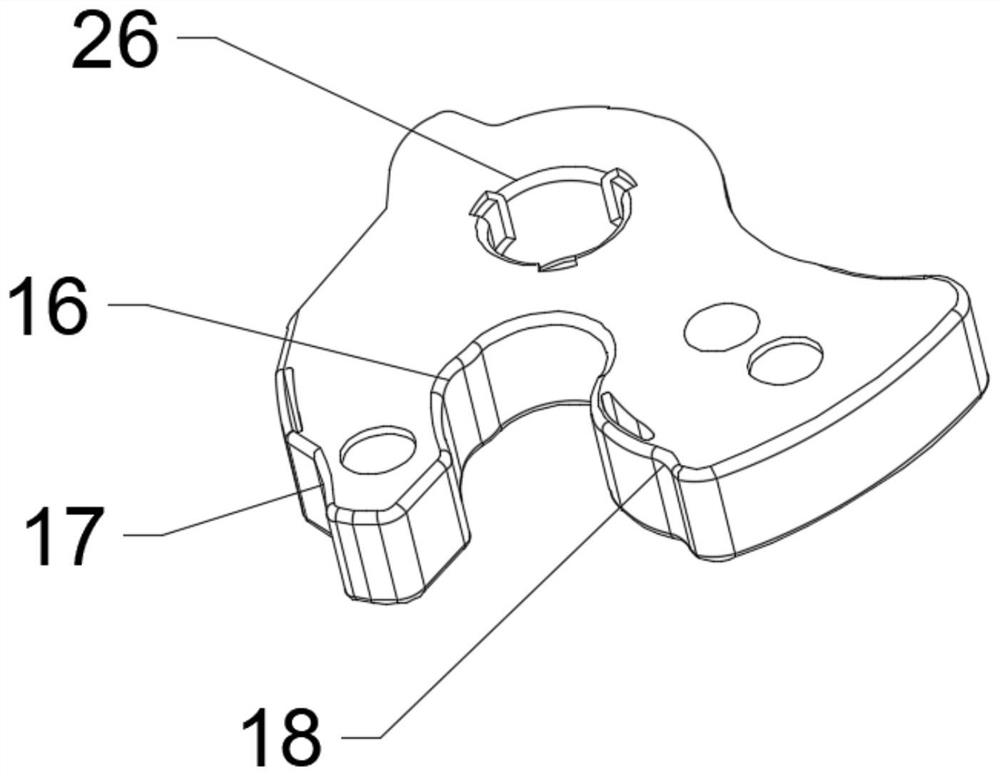

[0051] The lock tongue 8 is in transmission connection with the rotating member 2, and the lock tongue 8 rotates with the rotating member 2. The lock tongue 8 is provided with a lock groove 16 for holding the lock cy...

Embodiment 2

[0082] This embodiment provides a car lock structure, including a driving part 1, a rotating part 2, a lock bolt 8 for holding a lock cylinder, a brake part 9 for locking the lock bolt 8, and a brake part 9 for driving the lock cylinder. The unlocking part 29 that is unlocked with the lock tongue 8 and the linkage 4 that is used to contact and cooperate with the unlocking part 29 to realize unlocking.

[0083] The driving member 1 is in transmission connection with the rotating member 2, and the rotating member 2 is driven to rotate through the driving member 1 . The lock tongue 8 is connected with the rotating member 2 and moves accordingly, so that the lock tongue 8 is beneficial to hold the lock cylinder.

[0084] Linkage piece 4 is connected on the brake piece 9, and one end of linkage piece 4 extends to the stroke position of rotating piece 2, and is positioned on the stroke track of unlocking part 29, when pulling unlocking part 29 to move, contacts with linkage piece 4,...

Embodiment 3

[0089] This embodiment provides a car lock structure, including a driving part 1, a rotating part 2, a lock bolt 8 for holding a lock cylinder, a brake part 9 for locking the lock bolt 8, and a brake part 9 for driving the lock cylinder. The unlocking part 29 that is unlocked with the lock tongue 8 and the linkage 4 that is used to contact and cooperate with the unlocking part 29 to realize unlocking.

[0090] The driving member 1 is in transmission connection with the rotating member 2, and the rotating member 2 is driven to rotate through the driving member 1 . The lock tongue 8 is connected with the rotating member 2 and moves accordingly, so that the lock tongue 8 is beneficial to hold the lock cylinder.

[0091] Linkage piece 4 is connected on the brake piece 9, and one end of linkage piece 4 extends to the stroke position of rotating piece 2, and is positioned on the stroke track of unlocking part 29, when pulling unlocking part 29 to move, contacts with linkage piece 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com