Curing and drying control method for green plate curing and drying chamber

A curing drying and control method technology, applied in the direction of lead-acid battery electrodes, etc., to achieve the effect of reducing energy loss, reducing energy consumption, and reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in conjunction with specific embodiments.

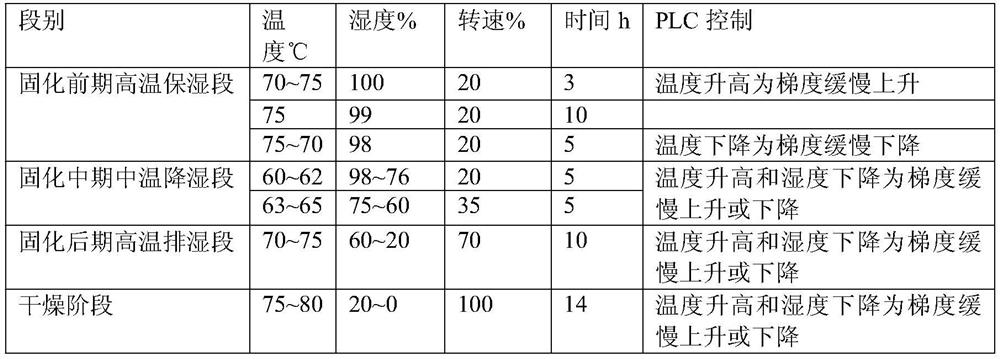

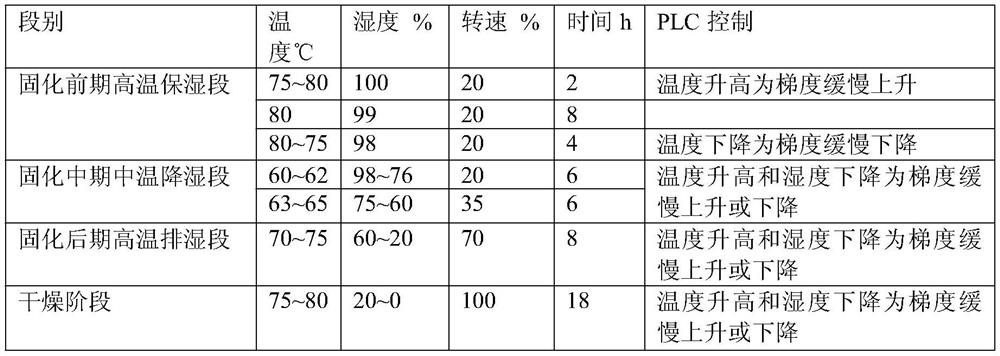

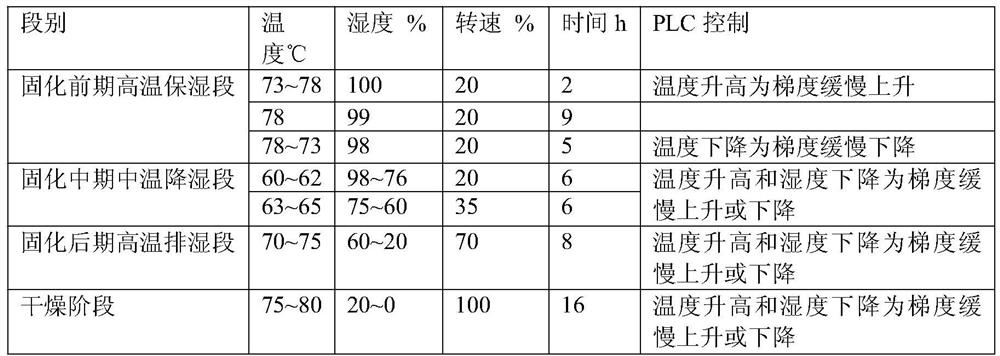

[0050] The invention discloses a curing and drying control method in a raw plate curing and drying room. The control method is realized based on four sets of temperature and humidity sensors respectively located at four corners in the curing and drying room. Wet section, high temperature dehumidification section after curing and drying stage;

[0051]1. The high-temperature moisturizing section in the early stage of curing accounts for 35%-45% of the entire curing time. It is realized by water atomization and steam spraying. The positive deviation between the fixed value and the process requirement is 0.5. In the early stage of curing, the high-temperature moisturizing stage is divided into three stages for each start and stop of water atomization and steam spraying: initial stage, middle stage and end stage:

[0052] 1) The initial stage is that there is no intermitten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com