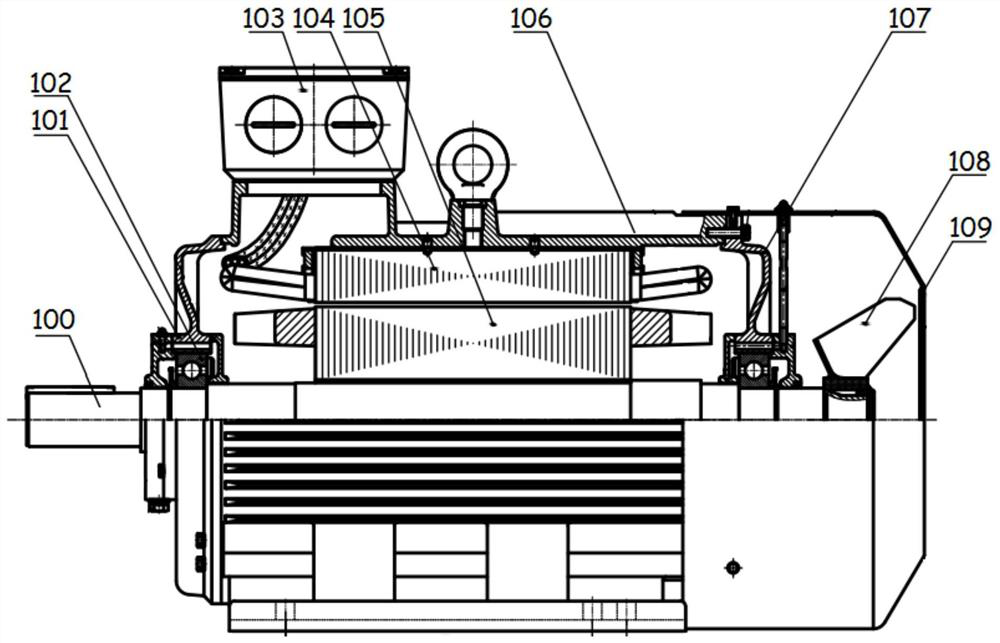

IE5 three-phase asynchronous motor based on stator unequal-groove punching sheets and cast-aluminum rotor

A three-phase asynchronous, cast aluminum rotor technology, applied in the direction of electric components, magnetic circuit rotating parts, electrical components, etc., can solve the problems of increasing product cost and not meeting the purpose of energy saving and consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

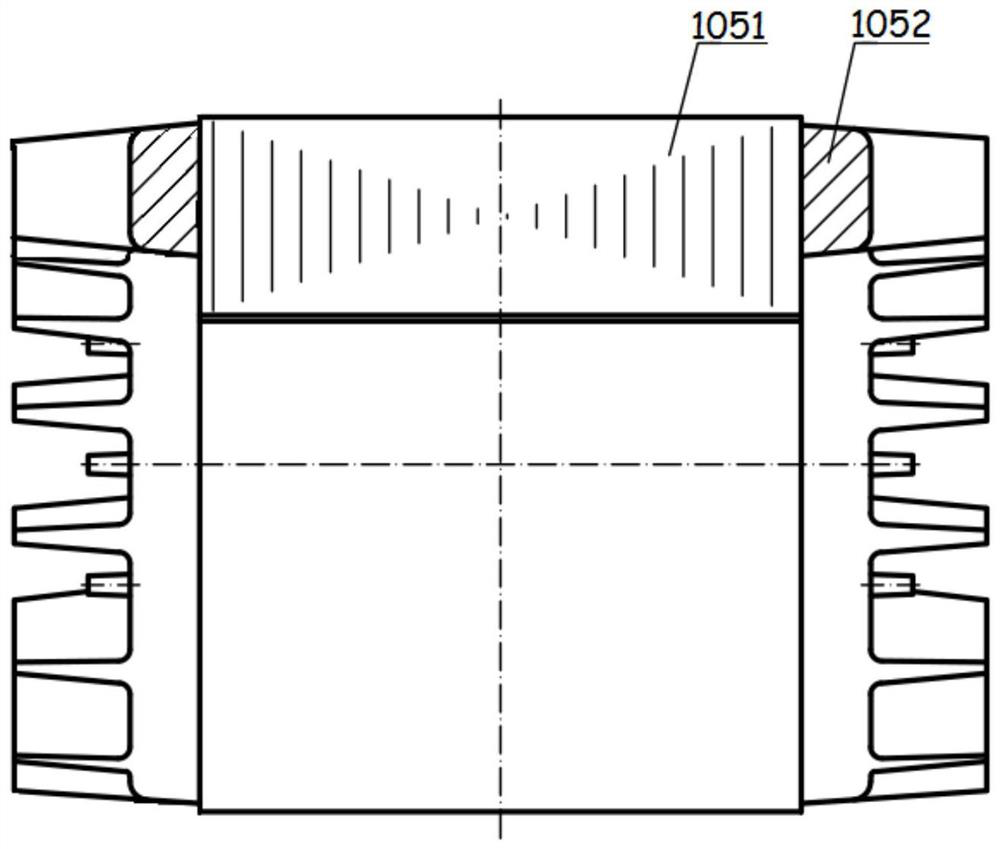

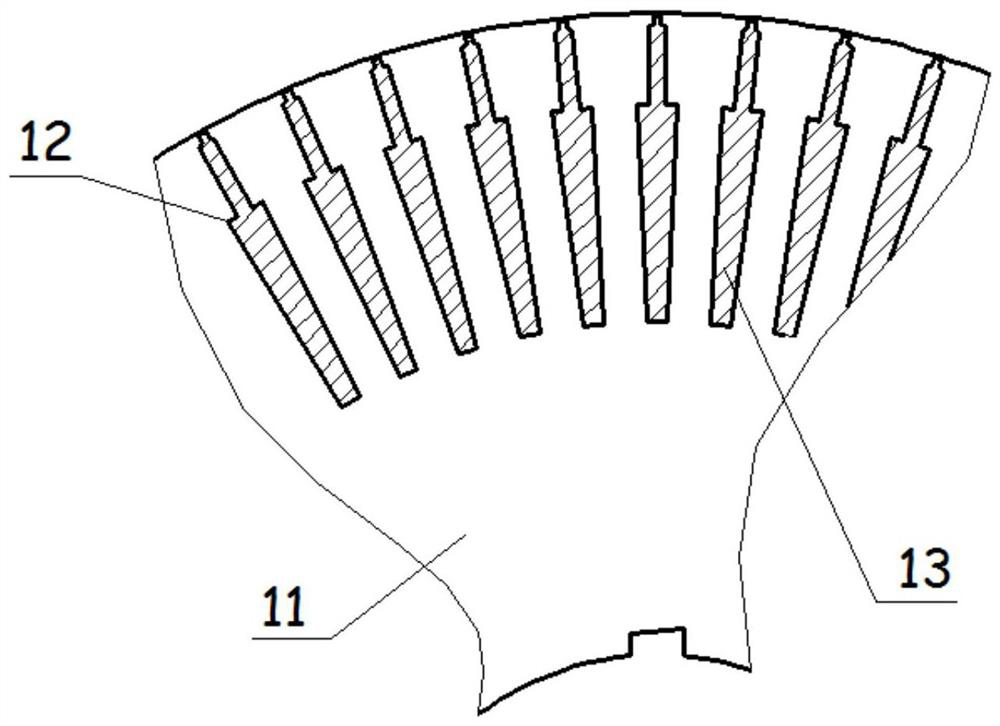

[0106] (1) Each stator slot group on the stator unequal slot punching sheet includes a plurality of large stator slots and small stator slots. Specifically, the stator unequal slot punching sheet includes a ring-shaped second substrate 1. On the inner circular surface of the second substrate 1, there are at least six sets of stator slot groups 2 for placing copper wires radially and uniformly arranged along the circumferential direction of the second substrate 1, and each set of stator slot groups 2 includes each pole and each phase. The number of stator slots is three to nine, including at least one large stator slot 26 and at least two small stator slots 25. The area of the small stator slots 25 is 80% to 95% of the area of the large stator slots 26, adjacent The central angles between the large stator slot 26 and the small stator slot 25 are equal; the distribution of the large stator slot 26 and the small stator slot 25 in each set of stator slot groups 2 is as follows:...

Embodiment 1

[0111] Such as Figure 5As shown, the stator unequal slot punching sheet used in the IE5 three-phase asynchronous motor based on the stator unequal slot punching sheet and the cast aluminum rotor of embodiment 1 includes a ring-shaped second substrate 1, according to the number of stages of the motor At least six sets of stator slot groups 2 for placing copper wires are evenly arranged radially on the inner circular surface of the second substrate 1 along the circumferential direction of the second substrate 1 . There are three stator slots per pole and per phase in each set of stator slot groups 2 , including one large stator slot 26 and two small stator slots 25 . The distribution of the large stator slot 26 and the small stator slot 25 in the stator slot group 2 is as follows: a large stator slot 26 is arranged in the middle of the stator slot group 2, and a small stator slot 25 is arranged symmetrically on both sides of the large stator slot 26, namely The small stator sl...

Embodiment 2

[0123] Such as Figure 12 As shown, the stator unequal slot punching sheet used in the IE5 three-phase asynchronous motor based on the stator unequal slot punching sheet and the cast aluminum rotor of embodiment 2 includes a ring-shaped second substrate 1, according to the number of stages of the motor At least six sets of stator slot groups 2 for placing copper wires are evenly arranged radially on the inner circular surface of the second substrate 1 along the circumferential direction of the second substrate 1 . There are four stator slots per pole and per phase in each set of stator slot groups 2 , including two large stator slots 26 and two small stator slots 25 . The distribution of the large stator slot 26 and the small stator slot 25 in the stator slot group 2 is as follows: two large stator slots 26 are arranged in the middle of the stator slot group 2, and a small stator slot is arranged symmetrically on both sides of the two large stator slots 26 25, that is, the sm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com