A high-efficiency deep baking process and its device

A baking and high-efficiency technology, which is applied in household refrigeration equipment, lighting and heating equipment, air heaters, etc., can solve the problems affecting the stability of product flavor, reducing the temperature rise rate of coffee beans, and not being able to achieve timely temperature control, etc., to achieve Good temperature control effect, product quality control, and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

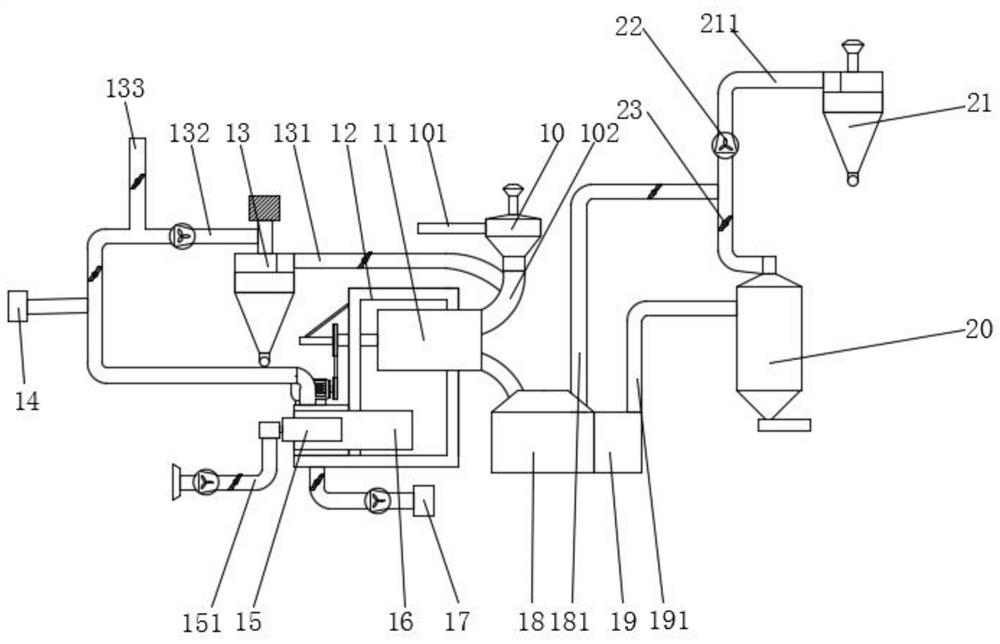

[0031] see Figure 1-4 As shown, a kind of high-efficiency deep baking process in the present embodiment comprises the following steps:

[0032] Step 1: Inhale air through the air suction pipe 151 of the high-efficiency deep roasting device, and deliver it to the burner 15, start the burner 15, burn in the combustion chamber 16, and store the heat energy generated by the combustion of the burner 15 in the combustion chamber 16 , with air as the main heat transfer medium, the heat energy in the combustion chamber 16 enters the heating chamber 12 and the roasting drum 11 to provide the heat required for roasting coffee beans;

[0033] Step 2: After weighing and batching all kinds of green coffee beans, the raw coffee beans are pneumatically transported from the feed port 101 to the green bean hopper 10, and the green beans are opened through the gate of the green bean hopper 10, and enter the roasting drum 11 from the roasting conveyor 102 For roasting, the first stirring blade...

Embodiment 2

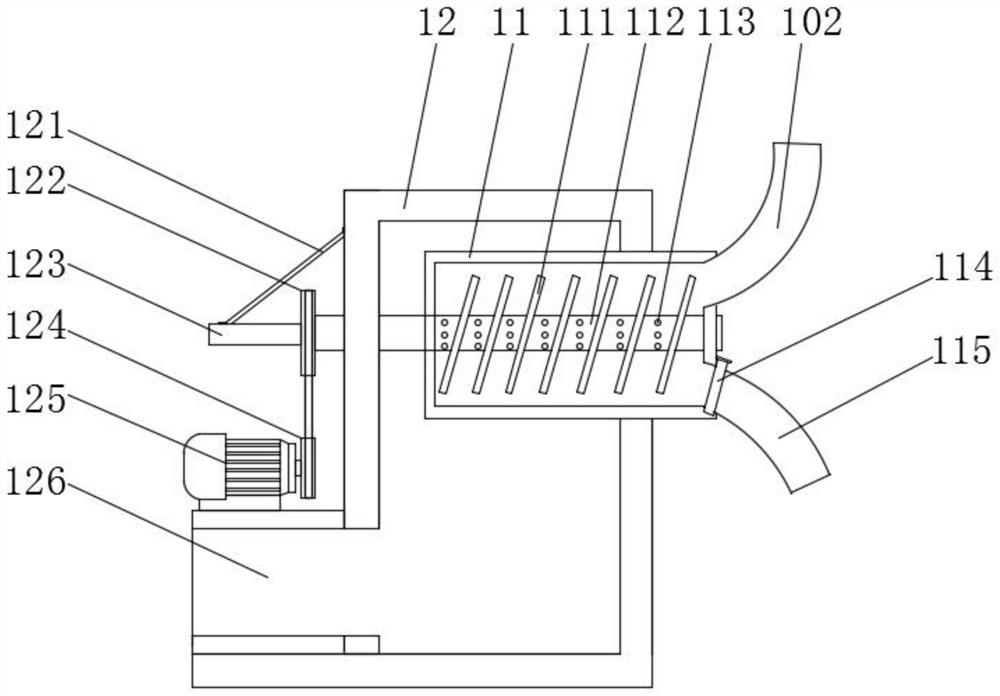

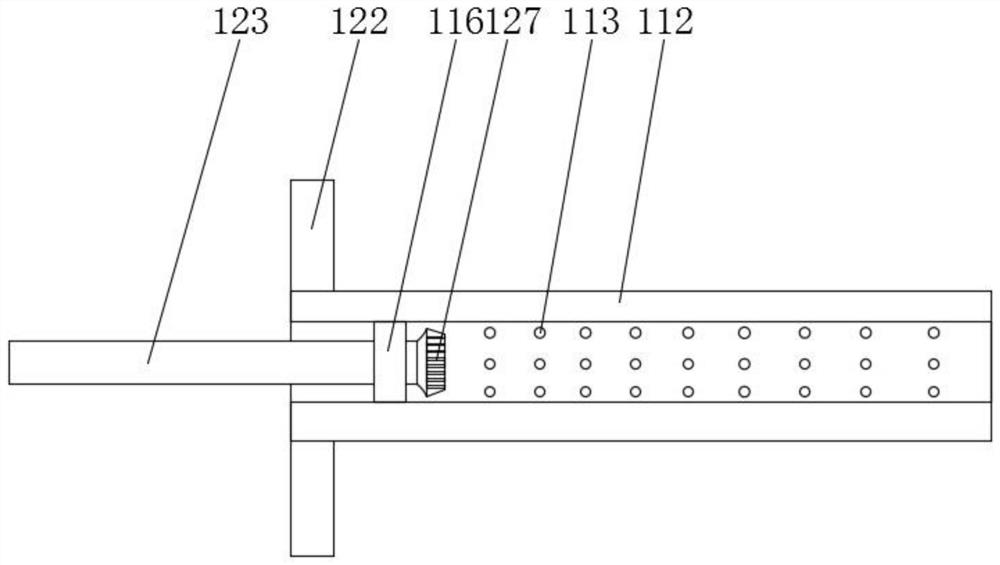

[0037] see Figure 1-4 As shown, a high-efficiency deep roasting device includes a green bean hopper 10, a roasting drum 11, a cooling plate 18, and a stone and rail removal track 19. A feed inlet 101 is installed on the top side of the green bean hopper 10, and the green bean A baking conveyor 102 is installed at the bottom of the hopper 10;

[0038] The end of the roasting conveyor 102 away from the raw bean hopper 10 is connected to the top of the roasting drum 11, the roasting drum 11 is installed on the top of the heating chamber 12, and the bottom of the heating chamber 12 away from the roasting drum 11 is provided with a mounting Port 126, a combustion chamber 16 is installed in the inner cavity of the installation port 126, a burner 15 is embedded in one end of the combustion chamber 16, an air suction pipe 151 is installed at the bottom of one end of the burner 15, and the baking drum 11 A roasted and cooked bean output port 115 is installed at the bottom of the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com