Dust removal method for textile fabric

A technology of textile fabrics and dust removal devices, applied in the textile field, can solve problems such as limited dust removal effect, and achieve the effect of improving dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

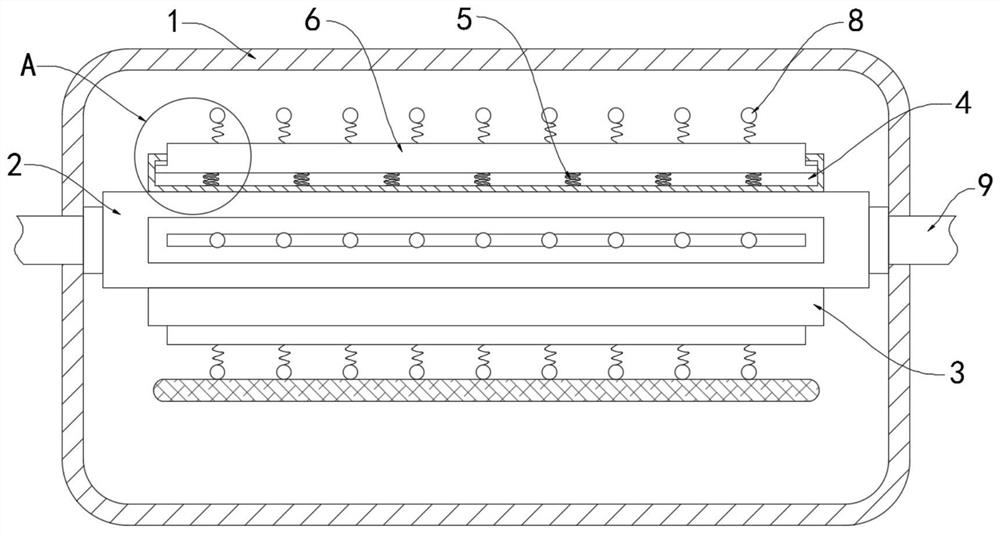

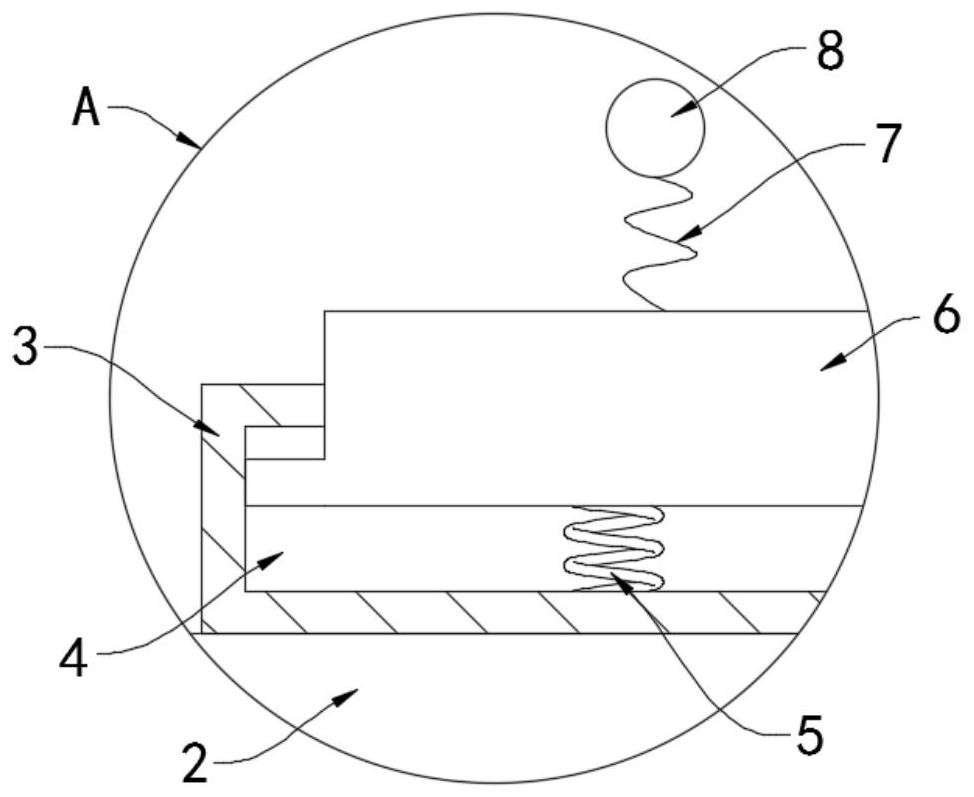

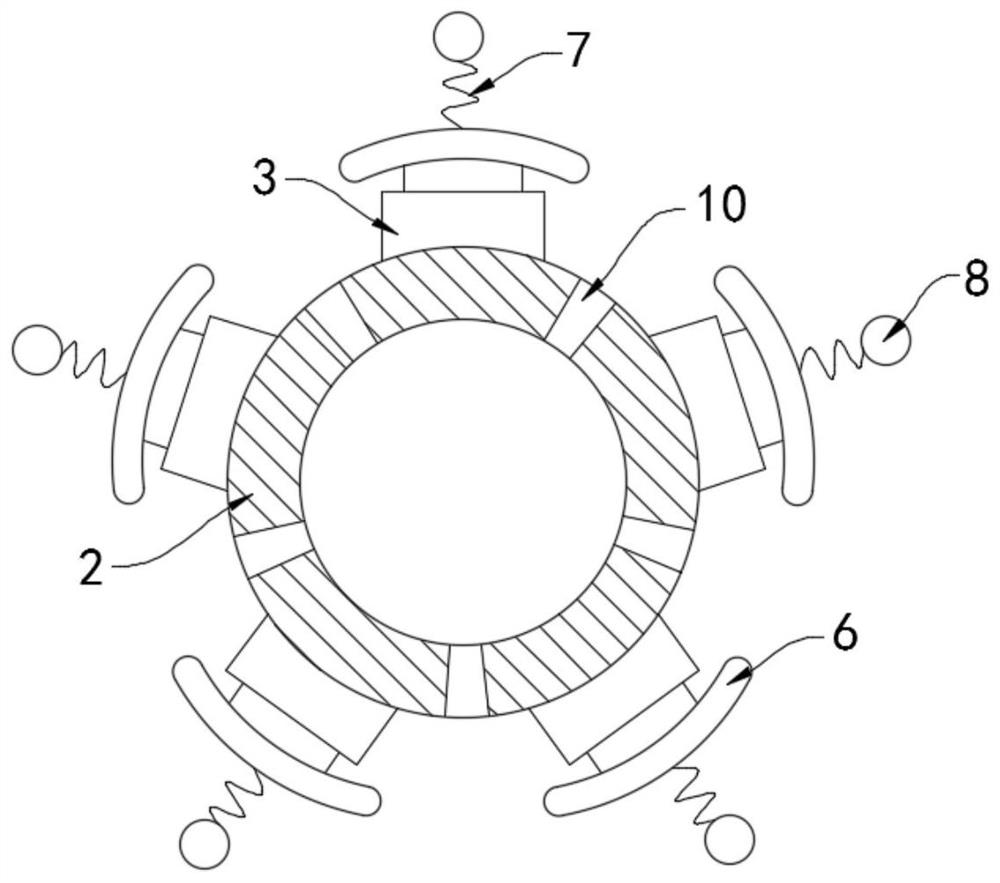

[0027] Such as Figure 1-3 Shown, a kind of dedusting method of textile fabric, concrete dedusting method is as follows:

[0028] S1. Place the fabric: the fabric first passes through the entire frame body 1, is located at the lower end of the rotating tube 2 and keeps a certain distance from the fixed box 3;

[0029] S2, slapping the cloth: during the rotation of the rotating tube 2, a plurality of conductive balls 8 will continuously slap on the cloth to raise the dust on the cloth;

[0030] S3. Electrostatic attraction: the sliding plate 6 and the rotating tube 2 can form a capacitor. When the distance between the sliding plate 6 and the rotating tube 2 changes, a current will be generated in the circuit, which will energize the conductive ball 8, thereby attracting the lift in the frame 1. dust from

[0031] S4. Remove dust: rotate the air continuously flowing in the tube 2 to reduce the internal air pressure, which will suck the dust in the frame 1 and adhered to the co...

Embodiment 2

[0043] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 lies in that a vibrating screen 11 arranged horizontally is fixedly connected to the frame body 1 .

[0044] In this embodiment, the fabric is tiled on the vibrating net plate 11. When the conductive ball 8 hits the fabric, it will drive the vibrating net plate 11 to continuously vibrate, which can play the role of shaking the fabric and shaking the dust on it, further Improve the dust removal effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com