Rotor structure of rotary valve for regenerative oxidation furnace

A technology of rotor structure and oxidation furnace, applied in the direction of valve shell structure, incinerator, valve details, etc., can solve the problems of complex structure of inner shaft 52, inconvenient disassembly and assembly, and inconvenient processing, so as to save materials and processing costs, Easy processing and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

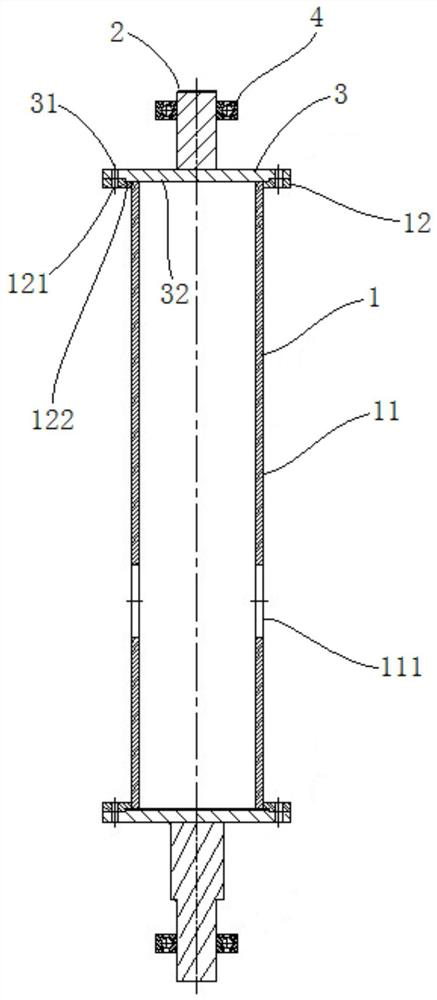

[0033] Such as figure 2 As shown, this embodiment provides a rotor structure for a rotary valve for a regenerative oxidation furnace, which includes a hollow sleeve 1 with a tube body 11 and two shaft heads 2, and the hollow sleeve 1 also includes two The first connecting piece 12 connected to the two ends of 11, the ends of the two shaft heads 2 are respectively connected with two second connecting pieces 3, and the two first connecting pieces 12 are detachable from the two second connecting pieces 3 respectively. connect. In this embodiment, the rotor structure of the rotary valve for the regenerative oxidation furnace is detachably connected with the two first connecting pieces 12 and the two second connecting pieces 3 respectively, so as to realize the connection between the two shaft heads 2 and the hollow sleeve 1 respectively. The two ends are connected. This connection method is convenient for disassembly and assembly, and saves the part of the shaft located in the h...

Embodiment 2

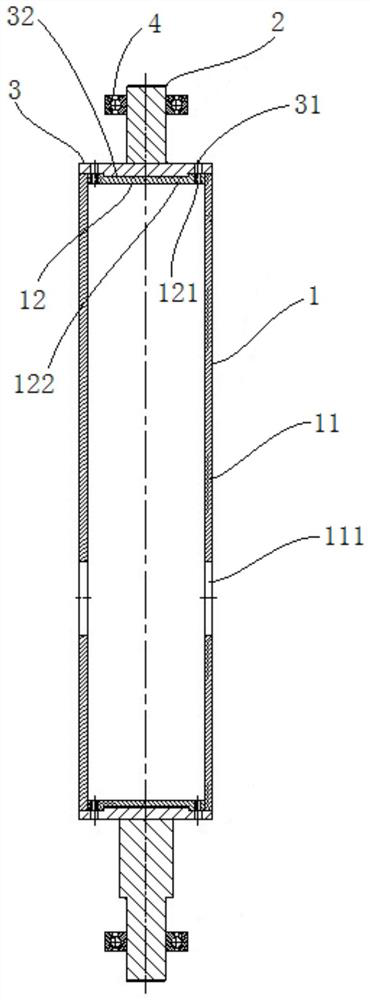

[0042] Such as image 3 As shown, this embodiment is based on the first embodiment above, and the difference is that in this embodiment, the first connecting piece 12 is fixedly connected to the inner wall of the pipe body 11, and the first connecting hole 121 is a threaded hole, and the bolt is connected to the first connecting piece. The side wall of the hole 121 is threaded. In this embodiment, the first connection piece 12 is located inside the pipe body 11 to save space, and the structure is more compact, and the first connection hole 121 on the first connection piece 12 is a threaded hole. When assembling, the bolt passes through the second connection The second connection hole 31 on the piece 3 is directly threaded with the side wall of the first connection hole 121, thereby realizing the detachable connection between the first connection piece 12 and the second connection piece 3, which is easy to operate and convenient for the first Assembly between the connecting pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com