Method for connecting at least one electrical contact element to a flat conductor for a vehicle electrical system of a motor vehicle

A technology of electrical contact elements and flat conductors, which is applied in the field of connection of flat conductors in vehicle power grids, can solve problems such as the adverse effects of structural heights, and achieve the effects of durable and stable welding connections, low cost, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

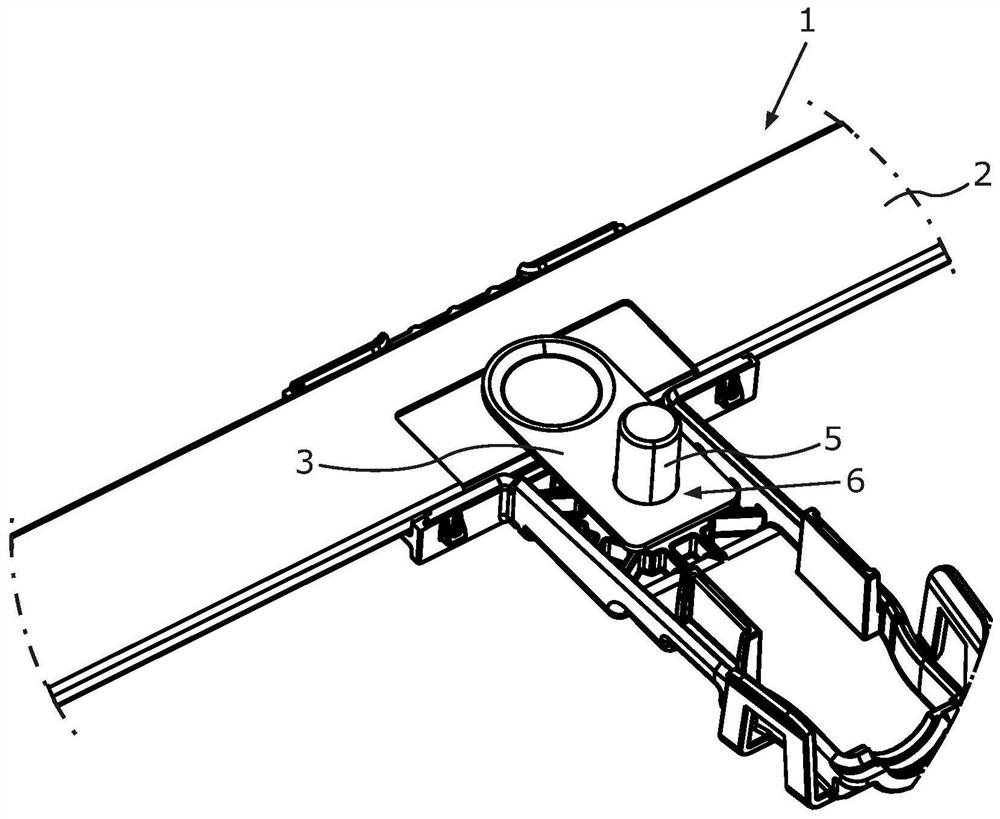

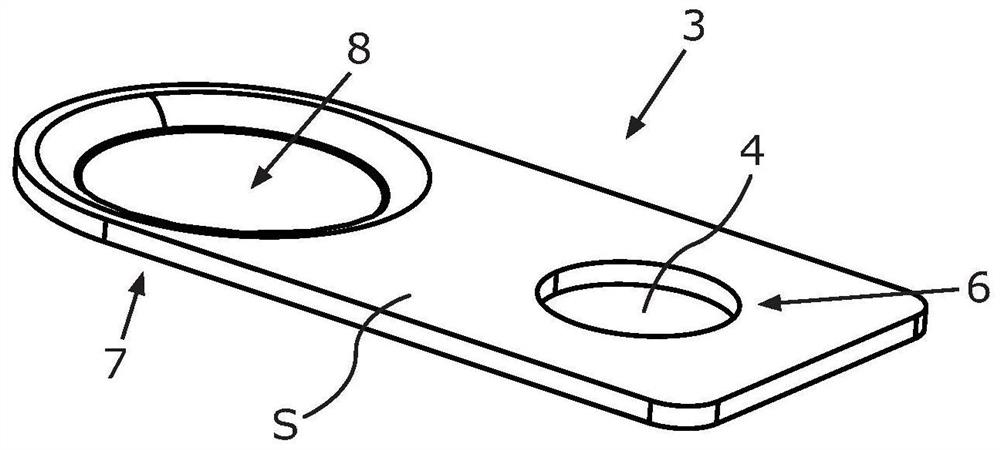

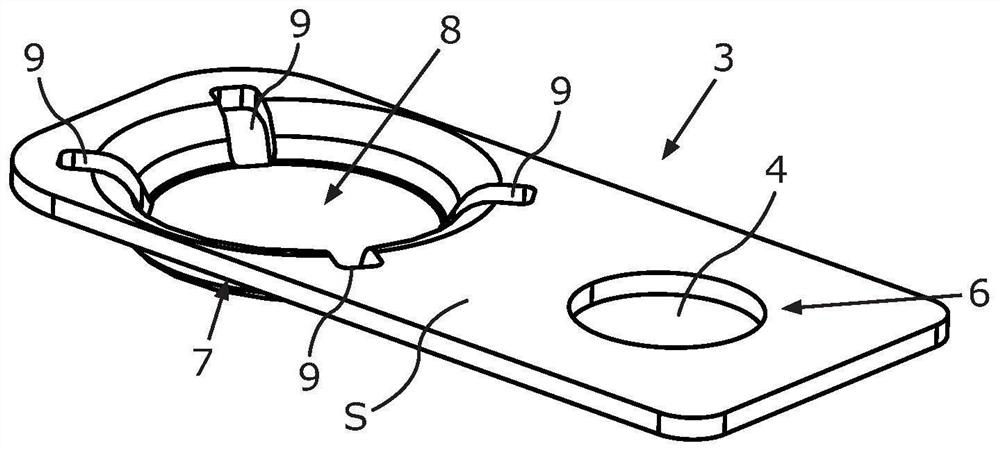

[0027] figure 1 A flat conductor 1 for an on-board electrical system of a motor vehicle is shown in perspective. The insulation 2 surrounding the flat conductor 1 is removed in one region. In this region, the electrical contact element 3 is connected to the partially deinsulated flat conductor 1 by friction welding. The bolt 5 passes through the through hole 4 not shown in detail here of the electrical contact element 3 (see figure 2 ).

[0028] For example, a cable lug can be slipped onto the screw 5 , which is then pressed onto the contact area 6 by screwing. Before being screwed on, the cable lug already accommodates, for example, a cable or a wire, which is then electrically conductively connected to the flat conductor 1 via the electrical contact element 3 . Contrary to what is shown in the figure, it is possible for several such electrical contact elements 3 to be connected to the flat conductor 1 at different points by friction welding.

[0029] figure 2 The ele...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap