Non-contact power supply device

A non-contact power supply and electric power technology, applied in the direction of circuit devices, battery circuit devices, electrical components, etc., can solve problems such as difficult control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

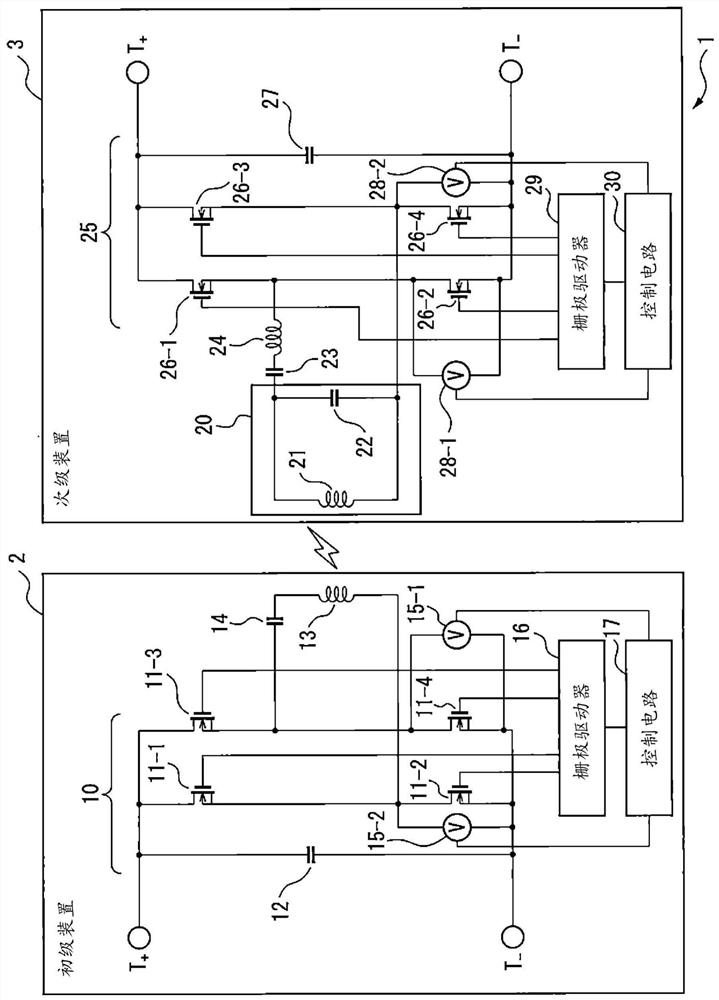

[0025] Hereinafter, a non-contact power supply device according to one embodiment of the present invention will be described with reference to the drawings. This non-contact power supply device has the same structure as the SPL system, thereby enabling bidirectional power supply.

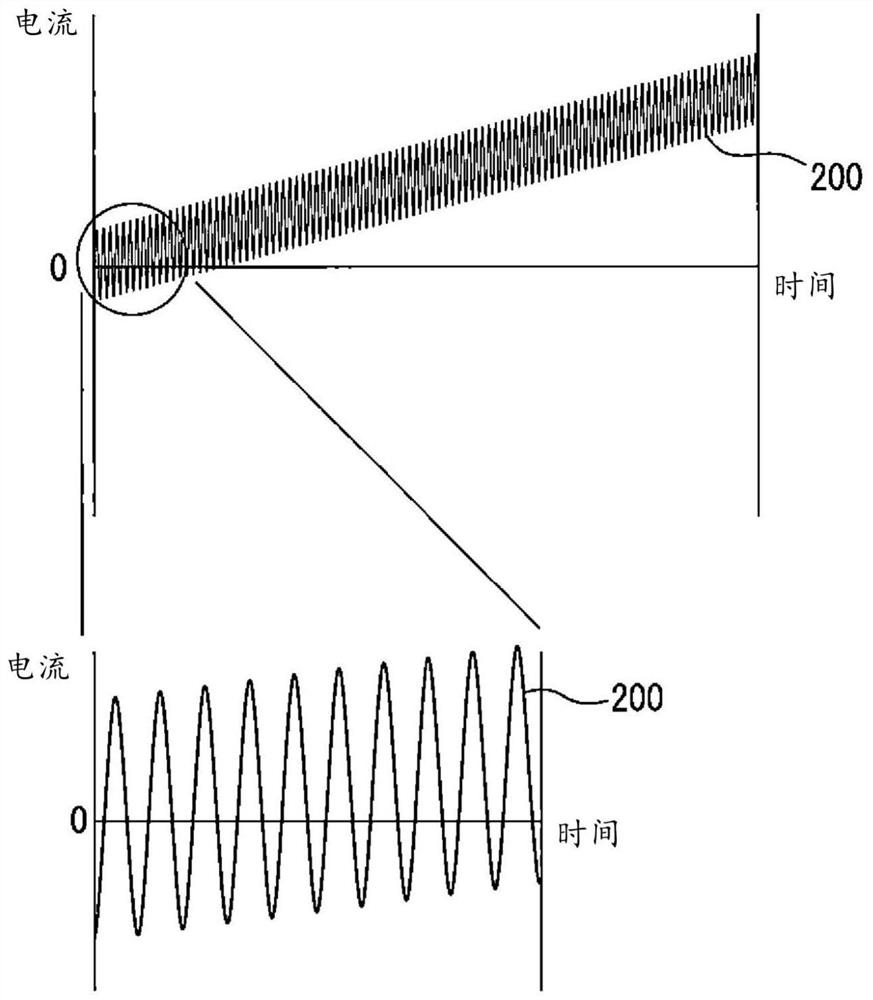

[0026] The inventors of the present application have noticed that in the non-contact power supply device of the SPL system, when power is supplied from the secondary side to the primary side, the circuit on the secondary side (in this case, the power supply side) where the bias excitation phenomenon occurs Too much current flows in the device, and switching elements such as MOSFETs are sometimes damaged.

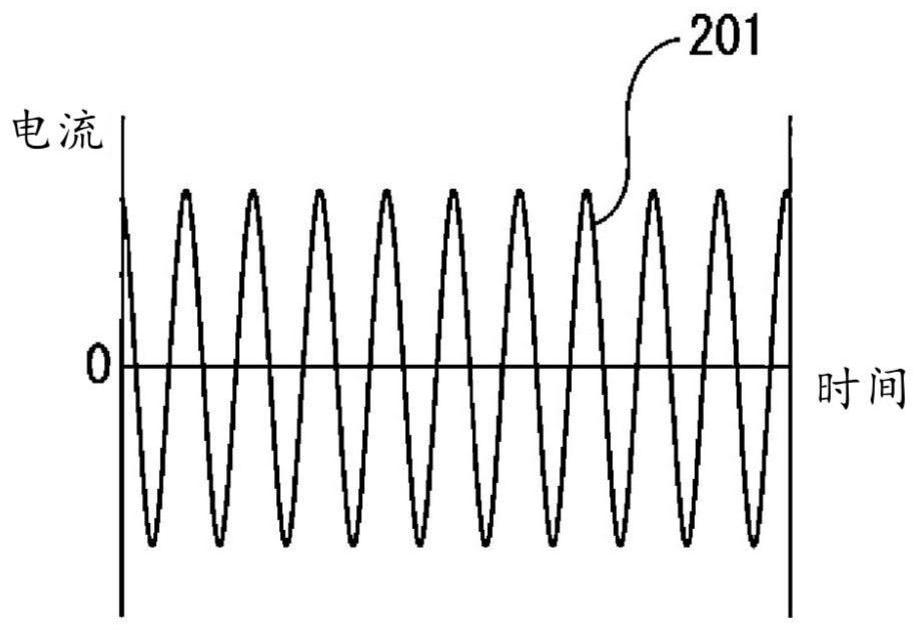

[0027] Therefore, this non-contact power supply device has a coil connected in series to the transmission coil in a device that resonates in parallel with a resonance capacitor for transmitting electric power (hereinafter referred to as a transmission coil) and has a coil connected in series with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com