A barrel-type roller grinding device for workpiece polishing

A technology for rolling and grinding workpieces, which is applied to machine tools suitable for grinding the edge of workpieces, grinding drive devices, and surface polishing machine tools, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

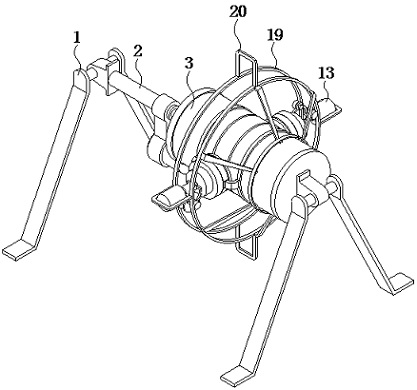

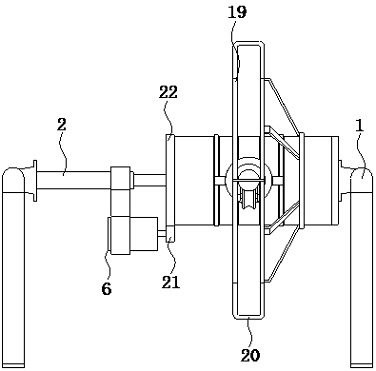

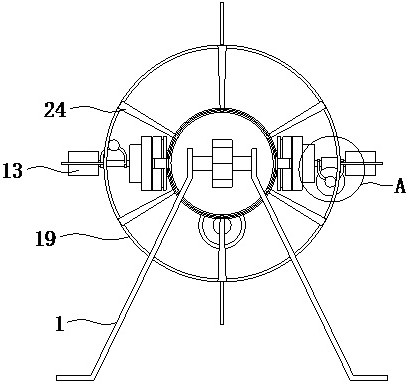

[0029] Embodiment one, such as Figure 1-8 As shown, a cylindrical barrel grinding device for workpiece polishing includes two brackets 1 and a hydraulic cylinder 2, the left end of the hydraulic cylinder 2 is fixedly connected to the bracket 1 on the left side, and two brackets are arranged between the two brackets 1 A barrel 3, the interior of the barrel 3 is a friction-like structure, which can play the effect of polishing the workpiece, the inner bottom wall of the barrel 3 on the right is fixedly equipped with a stop plate A4, and the barrel A4 on the right The right side of the barrel 3 is fixedly connected to the bracket 1 on the right side, and the output end of the hydraulic cylinder 2 is fixedly equipped with a stop plate B5, and the end of the stop plate B5 away from the hydraulic cylinder 2 is plugged into the barrel on the left side. 3, the size of the baffle plate A4 and the baffle plate B5 is the same, and the centers of the two baffle plates A4 and the baffle p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com