Plastic roll transfer device used in plastic bag production process

A production process and transfer device technology, which is applied in the field of plastic roll transfer devices in the plastic bag production process, can solve the problems of dropping, labor-intensive manual handling, and high labor intensity of the staff, and achieve simple operation and prevention of falling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

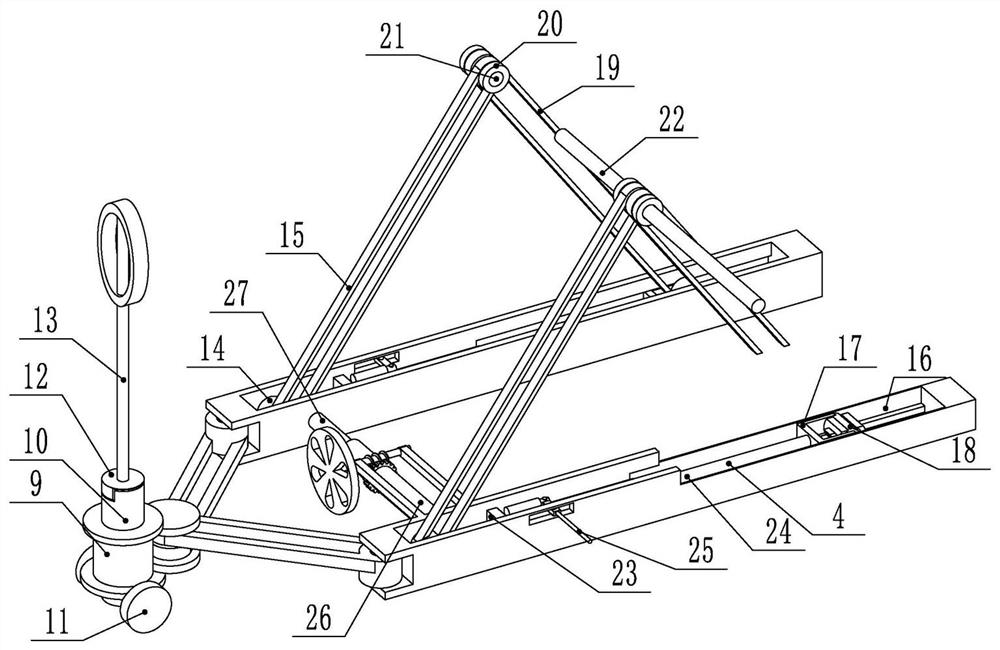

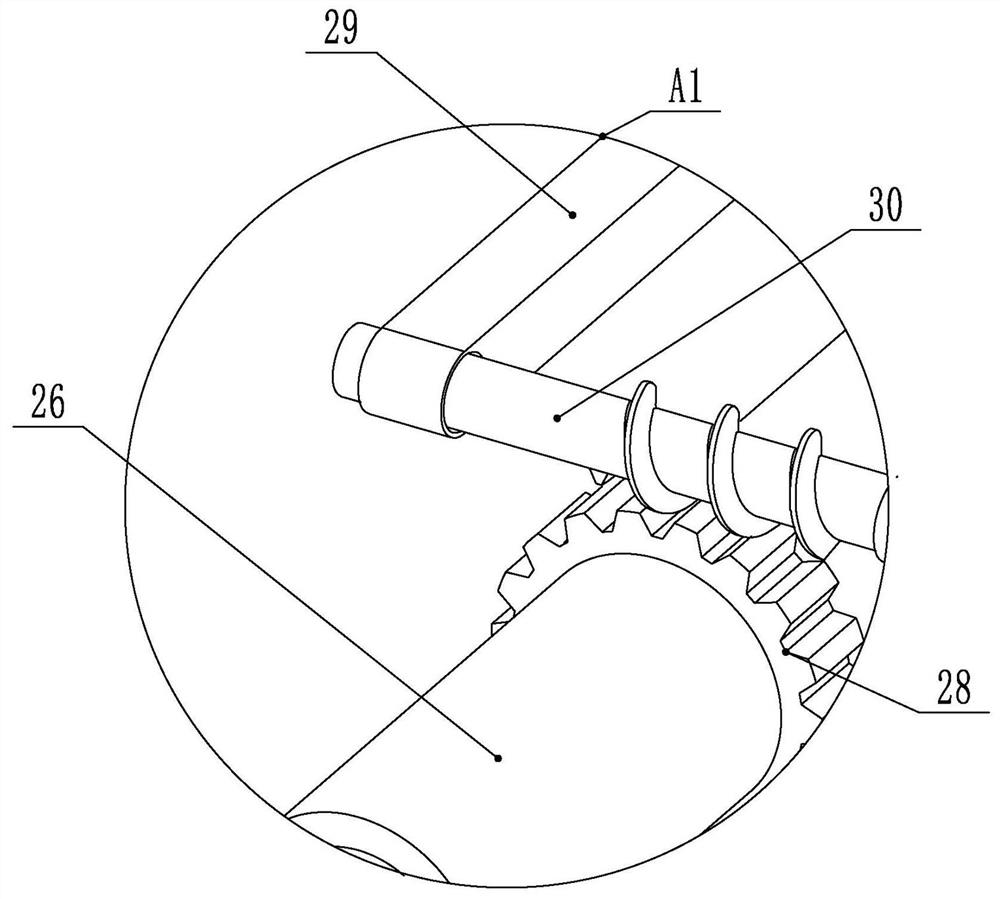

[0030] Embodiment 1, a plastic roll transfer device used in the production process of plastic bags, when in use, the whole is moved to the position where the plastic roll is by pulling the pull rod 13, and by turning the turntable 31, the worm wheel 28 and the worm screw 30 Under the action, the threaded sleeve 26 is driven to rotate, thereby changing the position of the threaded inner tube 27 in the threaded sleeve 26, expanding or reducing the distance between the left plate 5 and the right plate 6, and then pushing the pull rod 13 to connect the left plate 5 and the right plate 6. The right plate 6 is respectively located on both sides of the plastic roll, and the extension of the jack 24 is adjusted through the jack adjustment end 25, so that the position of the through hole 21 inside the connecting sleeve 20 corresponds to the position of the inner hole of the plastic roll, and then Insert the support rod 22, thus the plastic roll is fixed on the connecting sleeve 20, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com