Waste wire packaging device for building garbage recycling

A construction waste and wire technology, applied in packaging, bundling materials, parts of bundling machinery, etc., can solve problems such as hidden safety hazards, increase the workload of packaging belts, etc., and achieve the effect of tidy construction waste wires in rolls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

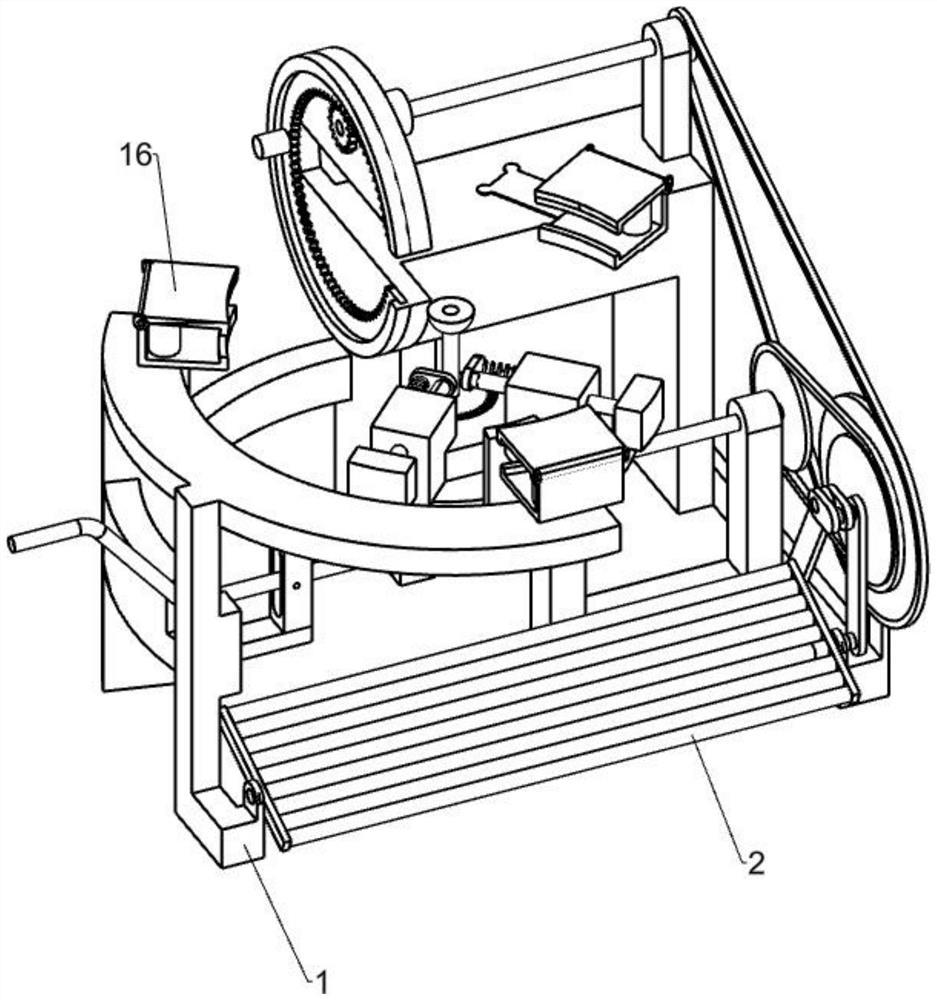

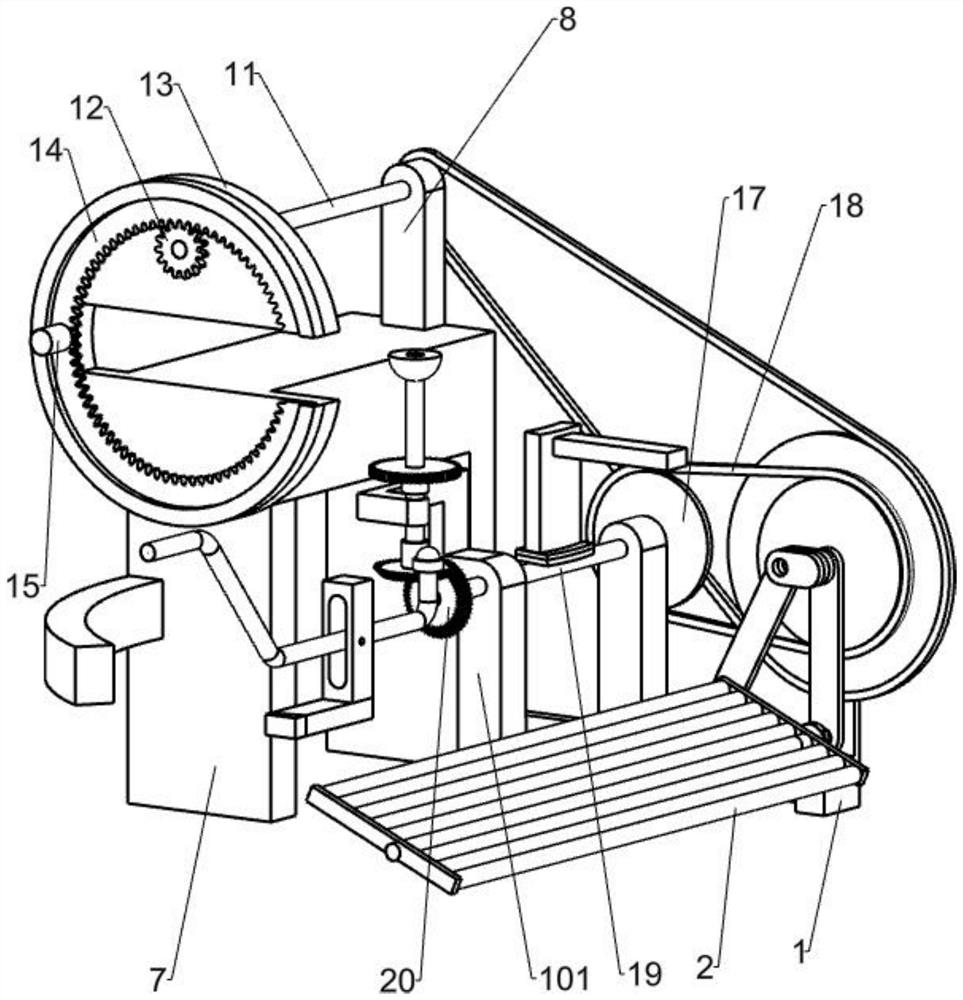

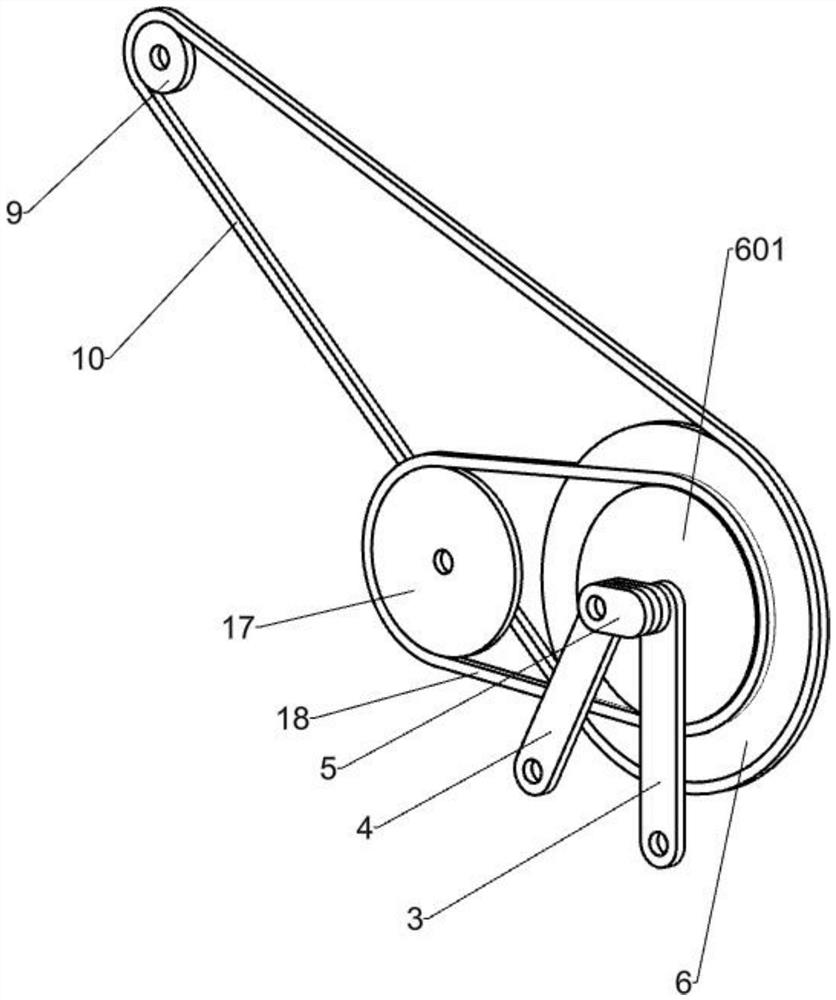

[0069] A waste wire packaging device for recycling construction waste, such as Figure 1-9 As shown, it includes a first bracket 1, a pedal 2, a connecting rod 3, a connecting rod 4, a connecting rod 3 5, a second transmission wheel 601, a first transmission wheel 6, a second support 7, a fixed support 8, a small Pulley 9, conveyor belt 10 and rolling parts, pedal 2 is rotatably connected to the left and right sides of the first bracket 1, connecting rod 3 is hinged to the right side of pedal 2, connecting rod 4 is hinged to the right side of pedal 2, and connecting rod 2 4 is located behind connecting rod 1 3, connecting rod 3 5 is hinged on connecting rod 1 3 and connecting rod 2 4, connecting rod 2 4 is eccentrically connected to the second transmission wheel 601, and the first transmission wheel 6 is fixed to the second transmission wheel On the right side of 601, the second bracket 7 is fixed behind the first bracket 1, the fixed bracket 8 is fixed above the second bracket ...

Embodiment 2

[0072] On the basis of Example 1, such as Figure 2-4 As shown, the scrolling component includes a first transmission shaft 11, a pinion 12, a rack fixing frame 13, a notched ring rack 14 and a tape placement block 15. The first transmission shaft 11 is fixed to the small pulley through a fixing bracket 8. 9. The pinion gear 12 is fixed to the end of the first transmission shaft 11, the rack fixing frame 13 is fixed to the left side of the second bracket 7, and the first transmission shaft 11 passes through the rack fixing frame 13, with a gap ring tooth The bar 14 is rotatably connected in the rack fixing frame 13, the pinion gear 12 meshes with the notched ring rack 14, and the tape placement block 15 is fixed to the left side of the notched ring rack 14.

[0073] When packaging the construction waste line, manually put the roll of construction waste line into the center of the rack holder 13, and then paste one end of the tape on the tape placement block 15 with the roll of con...

Embodiment 3

[0075] On the basis of Example 2, such as Figure 2-9 As shown, it also includes three limit sliding components. The three limit sliding components include a fixed base 16, a fixed cover 161, and a pulley 162. The fixed base 16 is fixed above the first bracket 1, and one of the fixed bases 16 is fixed. Above the second bracket 7, the fixed cover 161 is hinged to the fixed base 16, the pulley 162 is a pair, the pulley 162 is rotatably connected in the fixed base 16, and the upper side of the pulley 162 is close to the fixed cover 161.

[0076] When packaging the construction waste line, manually open the three fixed covers 161, and then put the rolled construction waste line inside, the outer edge of the rolled construction waste line contacts the pulley 162, and the fixed cover 161 is manually covered to form the roll building The waste line is fixed into a circle by the rack fixing frame 13 and the fixed cover 161, and the pedal 2 is manually pressed while the roll construction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com