A waste wire packaging device for construction waste recycling

A technology for construction waste and wire, which is applied in packaging, bundling materials, components of bundling machinery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

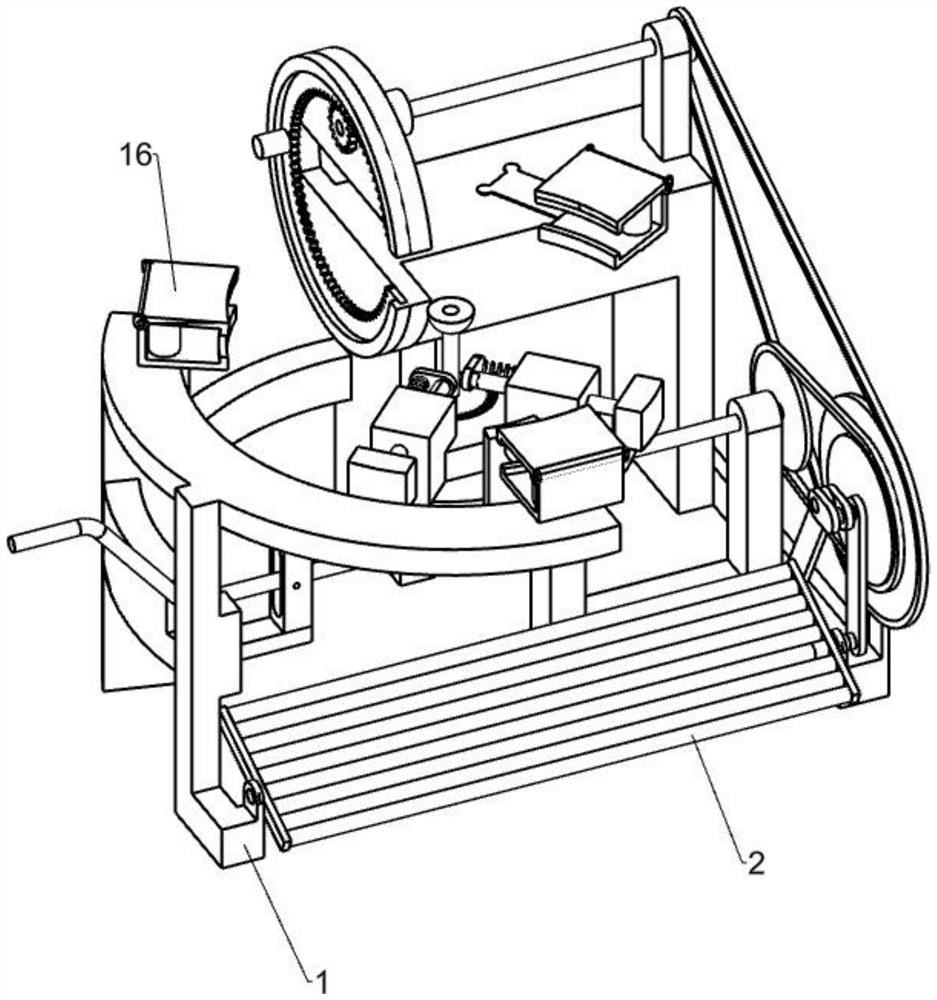

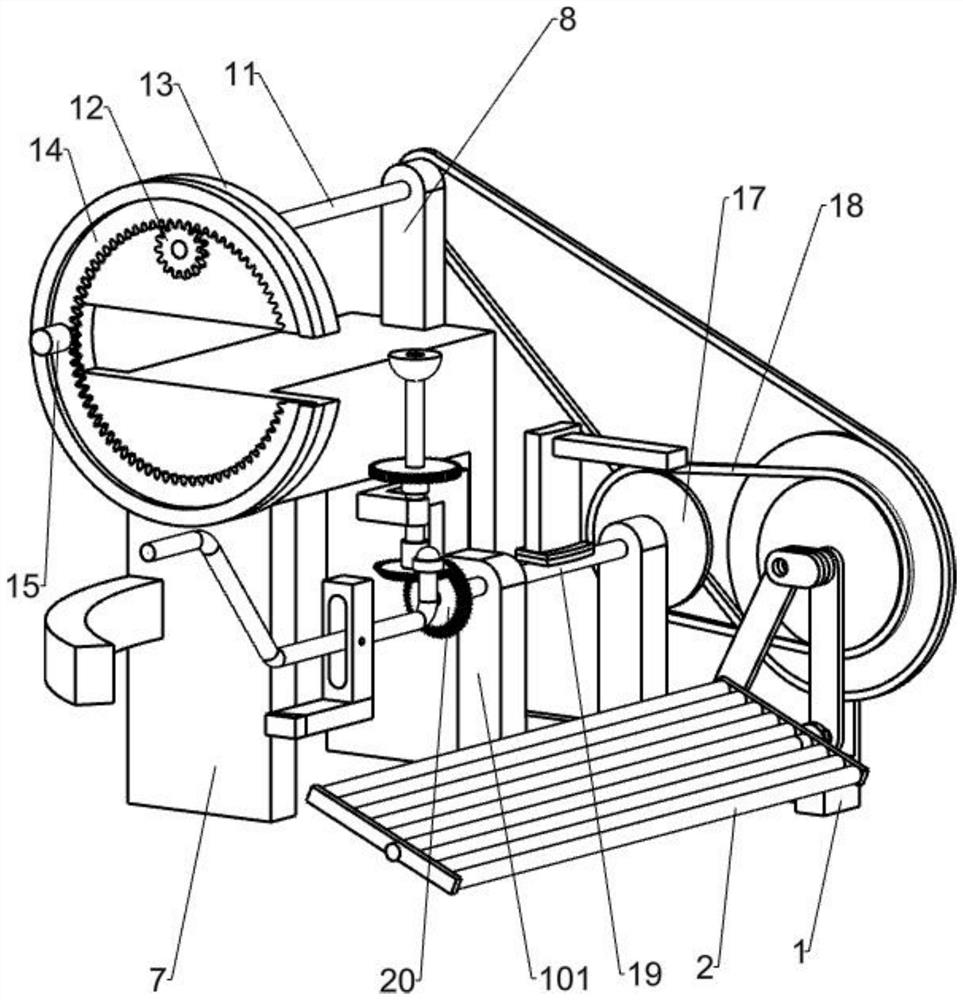

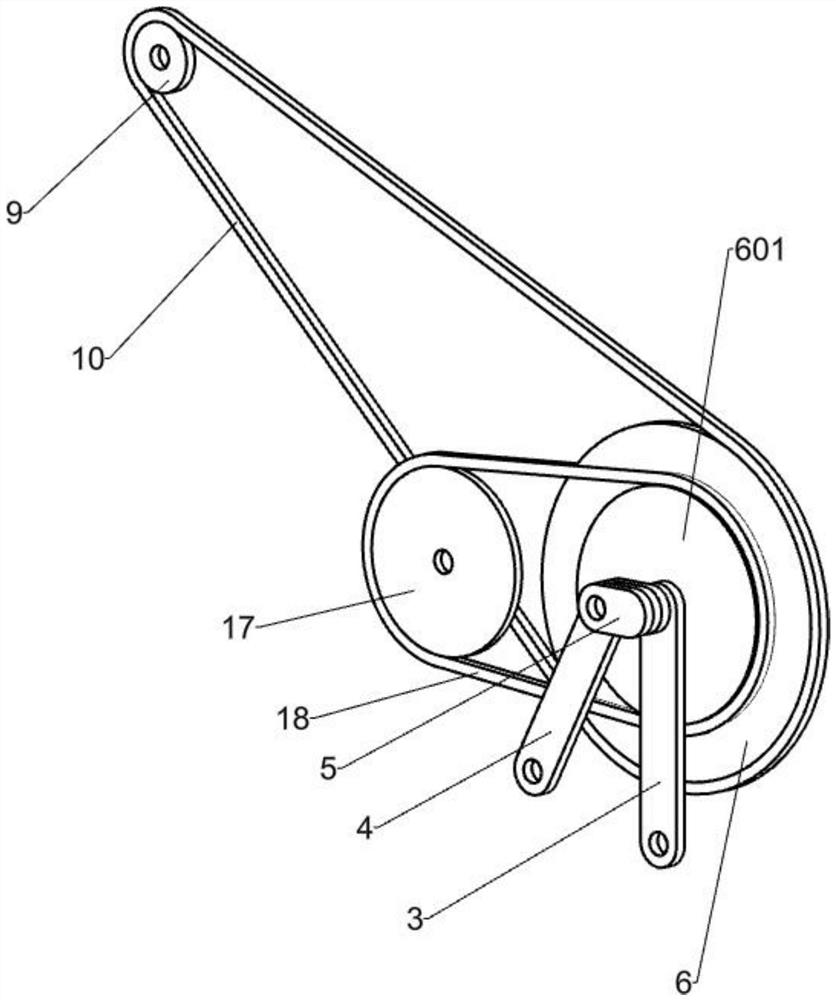

[0069] Construction garbage collection waste wire packaging device, such as Figure 1-9 As shown, including the first bracket 1, the pedal 2, the link one 3, the link two 4, the link three 5, the second drive wheel 601, the first transmission wheel 6, the second bracket 7, fixed bracket 8, small The pulley 9, the conveyor belt 10 and the rolling member, the pedal 2 is rotated to be connected to the left and right side of the first bracket, and the link one 3 is hinged on the right side of the pedal 2, and the link two 4 is hinged on the right side of the pedal 2, and the link is two. 4 Located behind the link one 3, the connecting rod three 5 hinged link one 3 is above the link 4, and the link two 4 is connected to the second drive wheel 601, and the first shift wheel 6 is secured to the second drive wheel. On the right side of the 601, the second bracket 7 is fixed to the first bracket 1, and the fixing bracket 8 is fixed to the second bracket 7, and the small pulley 9 is rotated ...

Embodiment 2

[0072] On the basis of Example 1, such as Figure 2-4 As shown, the rolling member includes a first transport shaft 11, a pinion 12, a rack fixing frame 13, a notch ring rack 14, and a tape placed block 15, and the first drive shaft 11 is secured to a small pulley through a fixed bracket 8. 9, the pinion gear 12 is fixed to the first transmitting shaft 11 end, and the rack fixing frame 13 is fixed to the left side of the second bracket 7, and the first transfer shaft 11 is placed above the rack fixing frame 13, the gap ring teeth The strip 14 is rotated within the rack fixing frame 13, and the pinion gear 12 is engaged with the gap ring zip 14, and the tape placed block 15 is fixed to the left side of the gap ring rack 14.

[0073] When packaged to the building, manual will be placed in the center position of the raw building 13, and then paste one end on the tape on the tape placed block 15, and the artificial foot pedal 2 rotates. The hand pushed the rolled construction, and the ...

Embodiment 3

[0075] On the basis of Example 2, such as Figure 2-9 As shown, there are three limit sliding assemblies, and the three limit sliding assemblies include a fixed base 16, a fixed cover 161, and a pulley 162, wherein the two fixed bases 16 are fixed above the first bracket, a fixed base 16. Following the second bracket 7, the fixing cover 161 is hinged to the fixed base 16, the pulley 162 is a pair, and the pulley 162 is rotated within the fixed base 16, and the pulley 162 is close to the fixed cover 161.

[0076] When packaging the building, artificially open three fixed cover 161, then put the rolled building waste line in the outer edge of the building, the outer edge of the building is in contact with the pulley 162, and manually will fix the fixed cover 161 cover, into the building The abandoned wire is fixed to a circle, artificial foot pedal 2, and the hand push-to-line construction waste line movement, and the outer edge of the building is sliding, the tape placed block 15 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com