Assembly-type ice wagon

An assembled, ice car technology, applied in skating, motor vehicles, transportation and packaging, etc., can solve the problems of uncomfortable sitting, inconvenient to carry, thin structure, etc., and achieve the effect of increasing fun, exercising the body, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

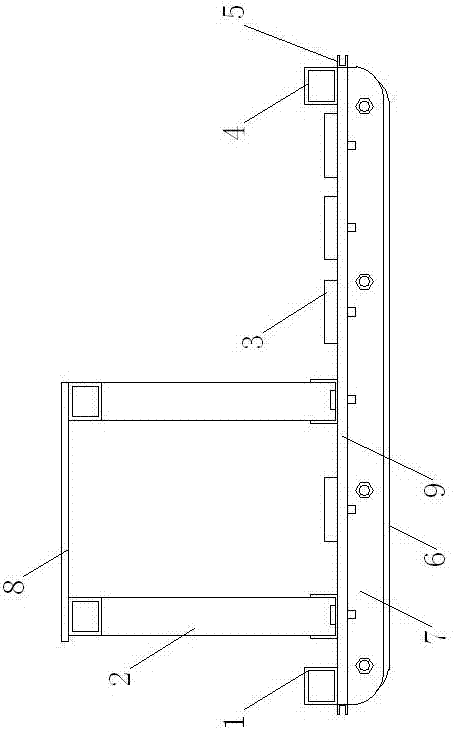

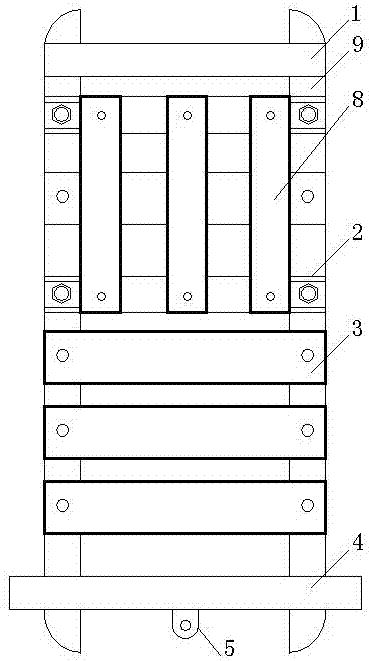

[0038] Embodiment one, as attached Figure 1-2 , 5-9 shown.

[0039] The frame body includes four vertical frames and two horizontal frames. The vertical frames are arranged vertically. The vertical frames are in an L-shaped structure. The bottom of the frame is welded and fixed with the feet. fixed. The foot seat is connected with the vehicle beam through connecting pieces such as bolts. The horizontal frame is arranged horizontally, and the horizontal frame is erected on the vertical frame and fixed by welding with the vertical frame. The feet at the bottom of the vertical frame can not only play the role of fixing the connection, but also strengthen the connection strength.

[0040] The vehicle beam includes two bottom beams 9, a front beam 4 and a rear beam 1. The tank bodies of the bottom horizontal section of the longitudinal frame are respectively installed on the bottom beam through connecting pieces. The front beam and the rear beam are fixedly arranged on the fr...

Embodiment 2

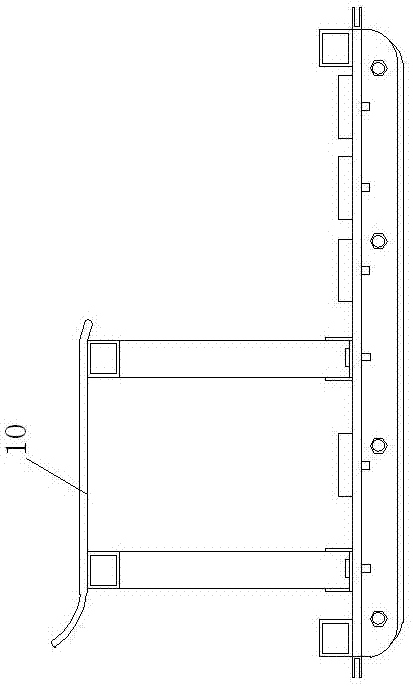

[0050] Embodiment two, as attached Figure 3-4 , 5-9 shown.

[0051] The overall structure of the ice trolley is the same as that of the first embodiment, and also includes a base 10 . A plurality of bolt seats are bonded to the bottom of the base, and each bolt seat corresponds to a prefabricated bolt hole on the horizontal frame, and is installed on the horizontal frame by bolts. The back of the base is an upturned curved surface structure, and the front is a downward curved surface structure. The entire base is a slightly lower middle part and slightly higher arc surface grooves around.

[0052] This kind of ice trolley is used in conjunction with ice drills. When selling or renting, different frames and ice drills are matched according to the user's own needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com