A method for clamping whole paper in a whole paper machine and automatic clamping whole paper machine

A paper machine and clamping technology, applied in the direction of transportation and packaging, thin material handling, sending objects, etc., can solve the problems of loose and messy paper, serious hand injury, and impact on work efficiency, so as to solve the pain and labor of hands , Accelerate the finishing speed and improve the finishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

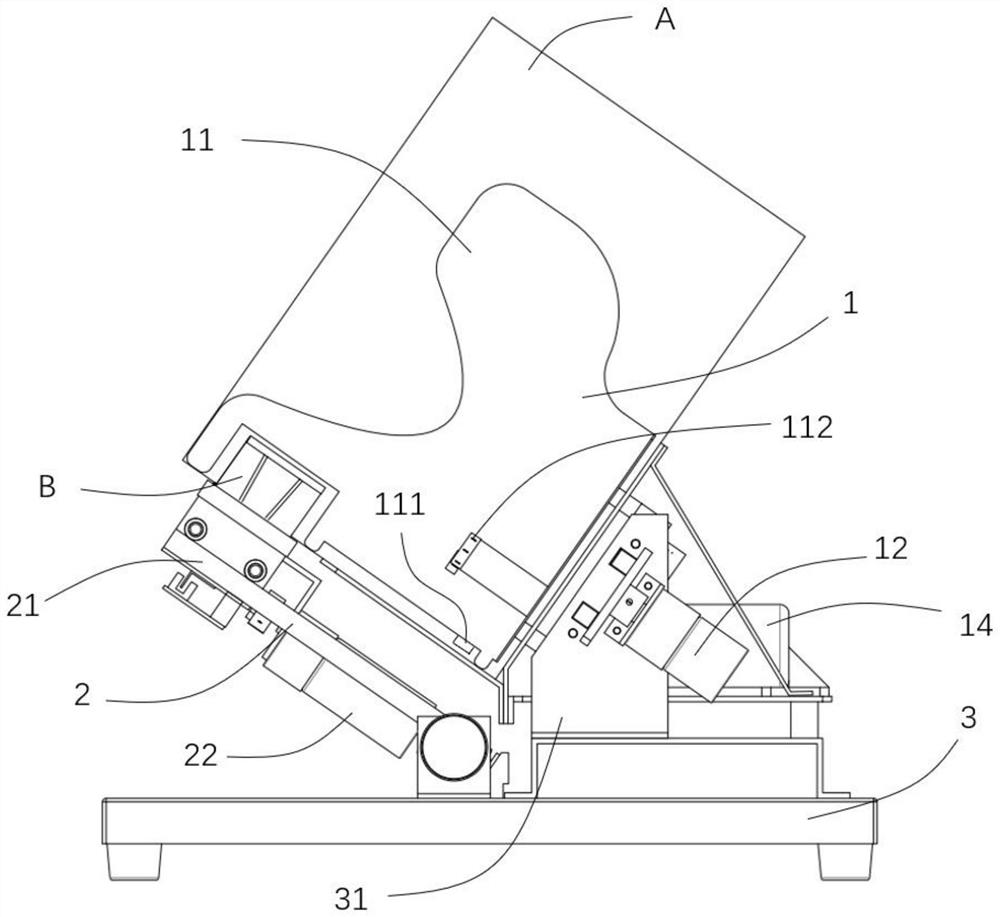

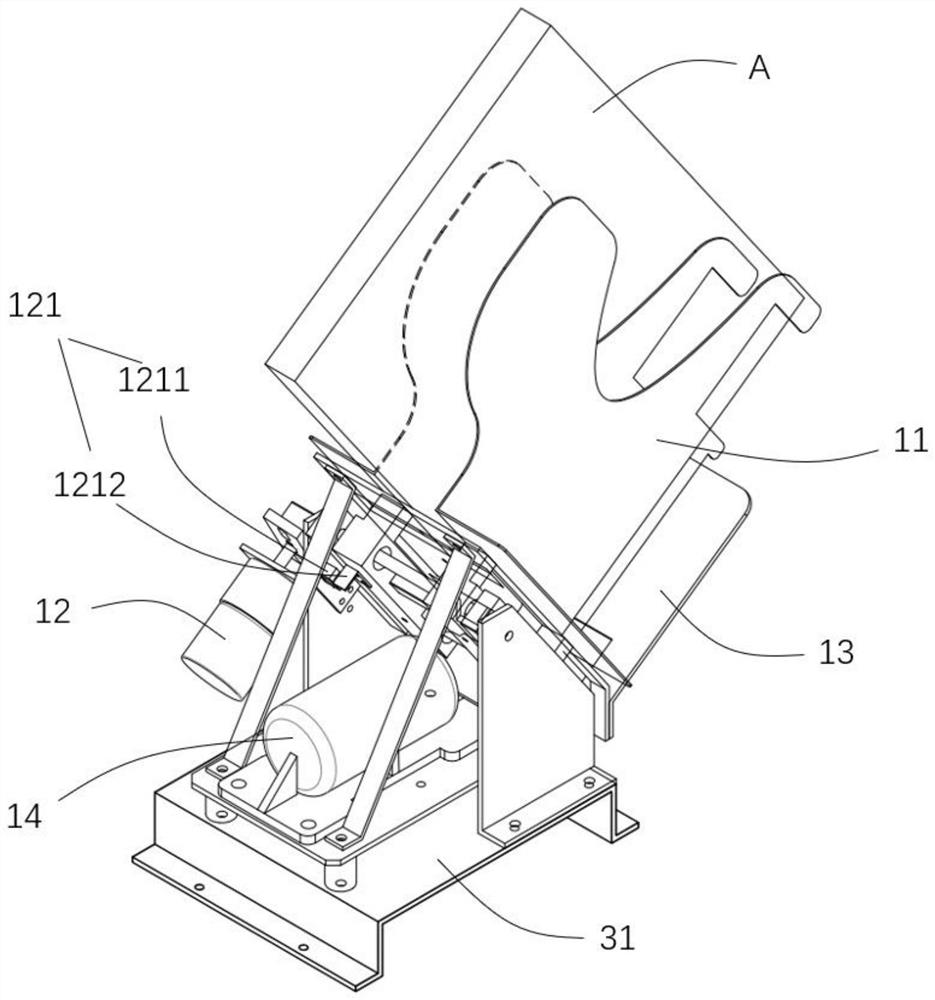

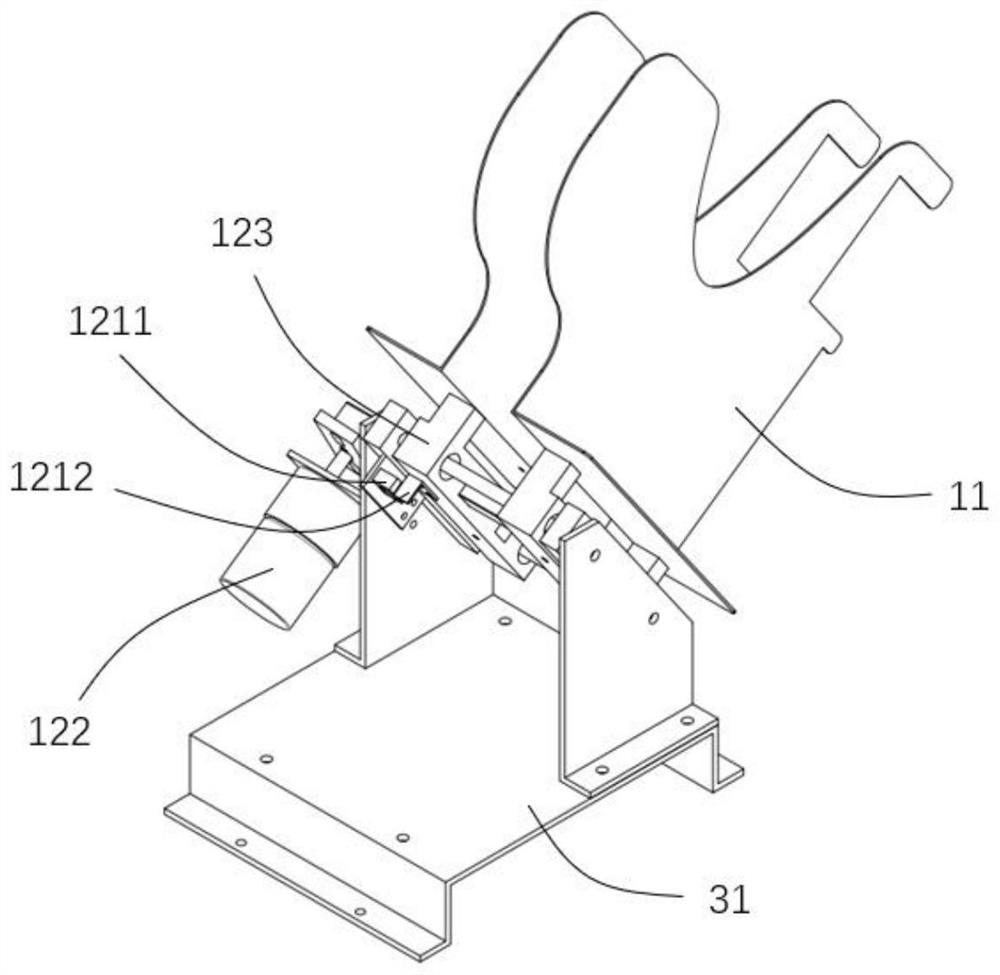

[0035] Embodiment 1 of the present invention provides a method for clamping whole paper in a paper machine, such as Figure 1-6 As shown, the whole paper machine includes a whole paper assembly and a clamping assembly, and the method includes the following steps:

[0036] S1, put the paper A between the two moving splints 11 of the whole paper assembly 1, while the bottom of the paper A rests on the vibrating pallet 13 of the whole paper assembly 1; install the paper clip on the clamping assembly 2;

[0037] S2, the moving splint 11 clamps the paper A for the first time, and then releases the paper A to form a gap with the paper A, and the vibration supporting plate 13 starts to vibrate until the paper A is neatly arranged;

[0038] S3, after the sorting is completed, the moving splint 11 clamps the paper A for the second time, and the clamping assembly 2 opens the paper clip B, so that the opening of the paper clip B is greater than the overall thickness of the paper A;

[0...

Embodiment 2

[0053] The second embodiment provides an automatic clamping machine, and the method for clamping the whole paper of the paper machine provided by the first embodiment is applied, such as figure 1 and 8 As shown, it includes the whole paper assembly 1, the clamping assembly 2 and the base 3, the whole paper assembly 1 and the clamping assembly 2 are installed on the base 3, the whole paper assembly 1 is electrically connected with the clamping assembly 2; the whole paper assembly 1 holds the paper After A is tidy, drive the dovetail clamp B on the clamping assembly 2 to clamp the paper in the paper assembly.

[0054] In this embodiment, the clamping assembly 2 is located below the whole paper assembly 1, and the lower end of the clamping assembly 2 is movably arranged on the base 3, and the whole paper assembly 1 is installed on the base 3 through the bracket 31; when clamping, the clamping Assembly 2 is turned over so that the dovetail clip B on its upper end is lifted to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com