A coating composite preparation process suitable for slotted needles

A preparation process, technology of grooved needles, applied in metal material coating process, superimposed layer plating, coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

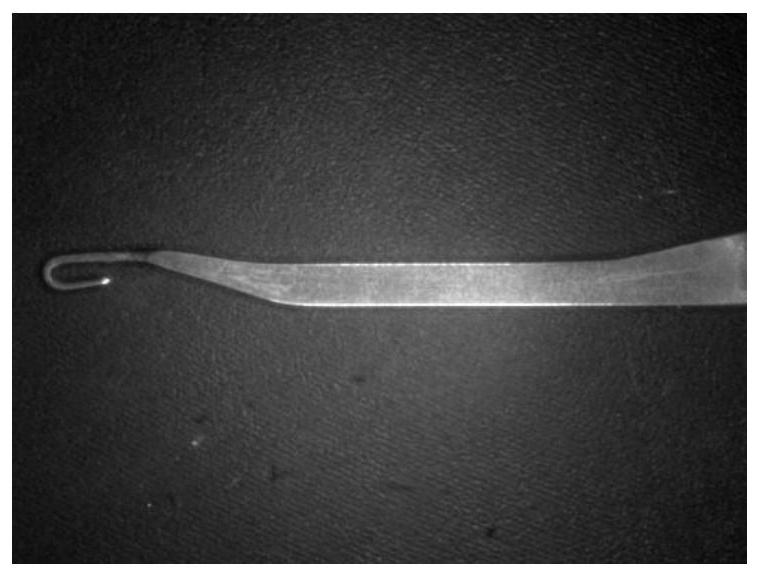

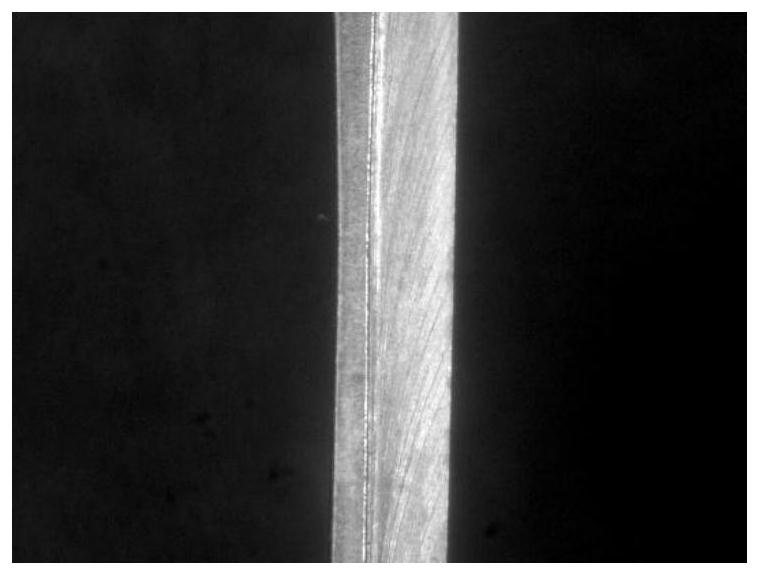

[0027] After polishing, degreasing and derusting the grooved needles, put them into dilute acid for acid etching and activation for a period of time, clamp several grooved needles with a jig, and apply a pre-plating layer (Cu layer or Ni layer) on the surface of the grooved needles . After the pre-plating coating is finished, rinse the surface of the groove needle with flowing deionized water. At the same time, set the pH value of the chrome plating solution (pH=2), the required temperature (20°C) and the cathode current density (10A / dm 2 ) Within a suitable range, put the fixture with the grooved needle after cleaning into the chrome plating solution, and electroplate the grooved needle for a period of time (15min). After the electroplating is completed, the groove needle is taken out from the fixture, rinsed with flowing deionized water, dried in a vacuum oven, and measured (digital Vickers hardness tester, load 100g, loading time 10s) the microhardness of the groove needle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com