Method for large-scale preparation of efficient electrolyzed water catalyst by using positive electrode material of waste lithium ion batteries

A lithium-ion battery, large-scale preparation technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of promoting electrocatalytic kinetic process, volume change , the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

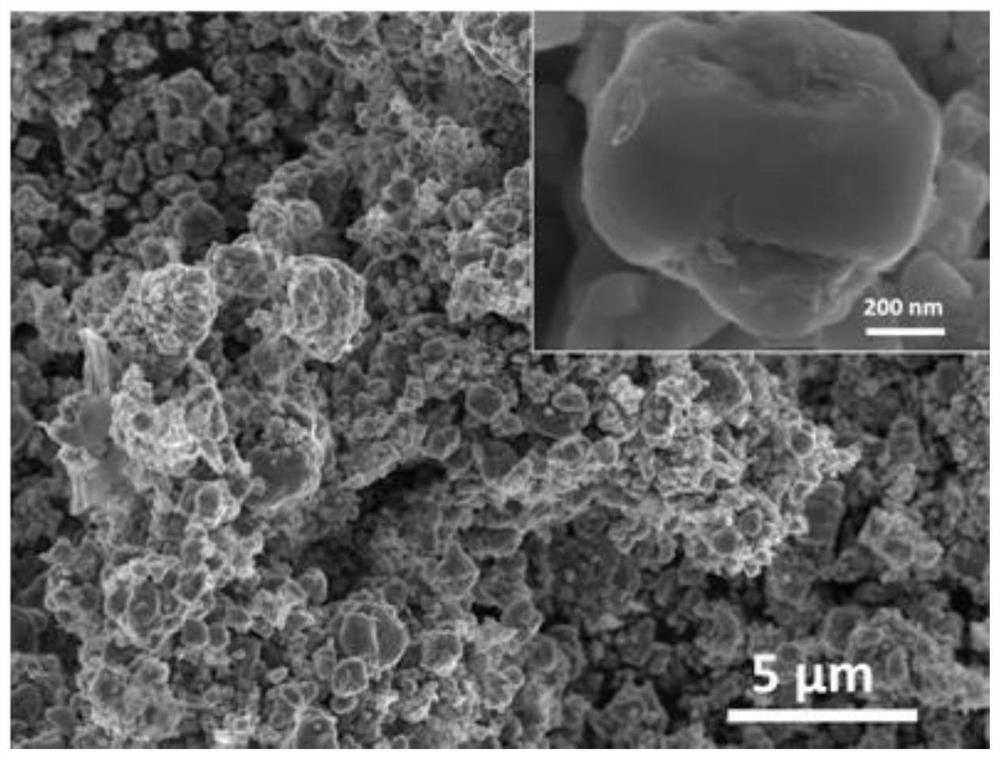

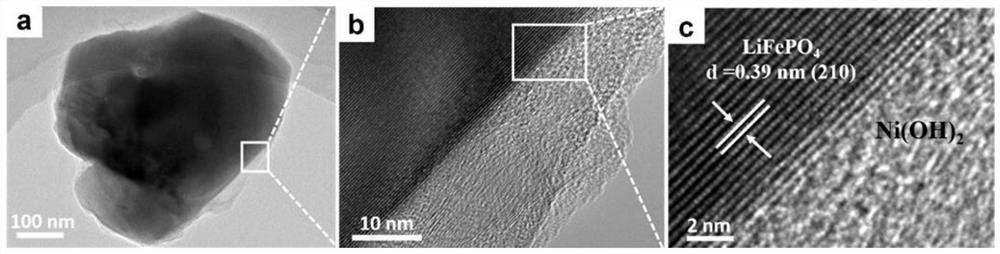

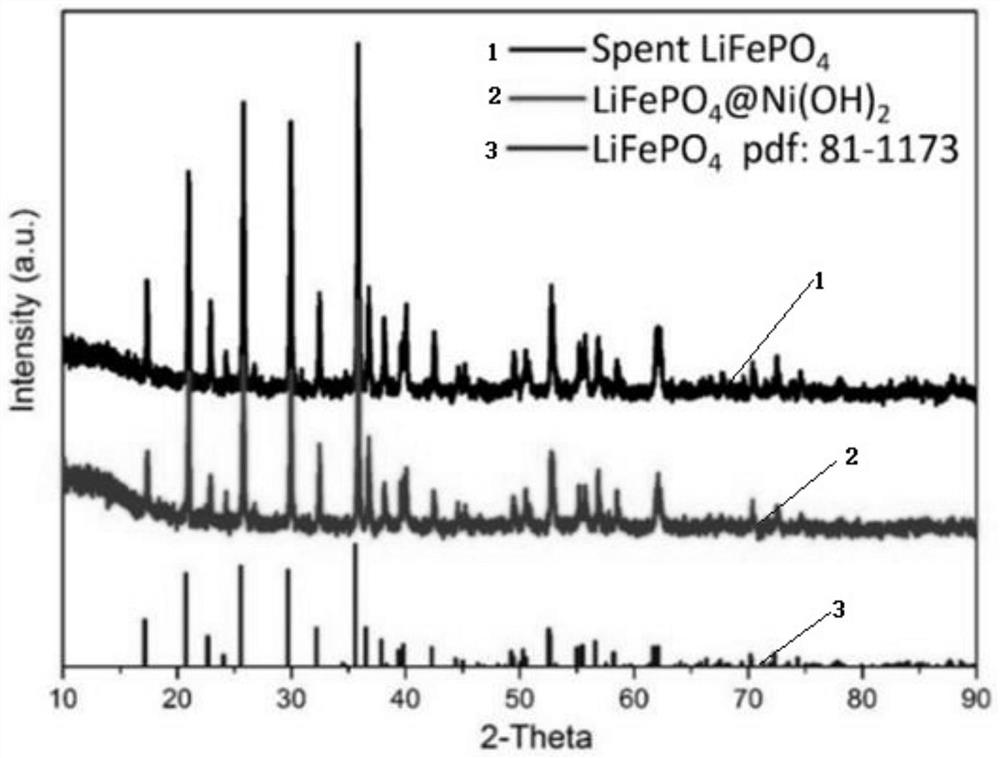

[0027] The technical solutions of the present invention will be further described below in conjunction with specific embodiments. The waste and old lithium ion battery cathode material that the present invention adopts is LiFePO 4 , that is, LiFePO, one of the most commercialized cathode materials 4 Take the preparation of large-scale and high-efficiency water electrolysis catalyst as an example.

[0028] Dissolve 0.16g of nickel nitrate hexahydrate into 10mL of pure water to form a homogeneous solution (that is, nickel nitrate is evenly dispersed in water); waste lithium-ion battery cathode material LiFePO 4 The powder is sieved, and the large-sized impurities are removed after sieving, and the positive electrode material powder with a particle size of less than 10 μm is collected, and then 0.03g LiFePO 4 After the waste powder is added to the solution, use an ultrasonic cleaning machine to ultrasonically disperse to form a uniform dispersion. The ultrasonic time is 8 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com