Centrifugal compressor basic level testing device capable of being adjusted in combined mode

A technology for centrifugal compressors and testing devices, which is applied to components of pumping devices for elastic fluids, mechanical equipment, non-variable displacement pumps, etc., to save replacement and installation time, production costs and testing costs, and good equipment. Guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

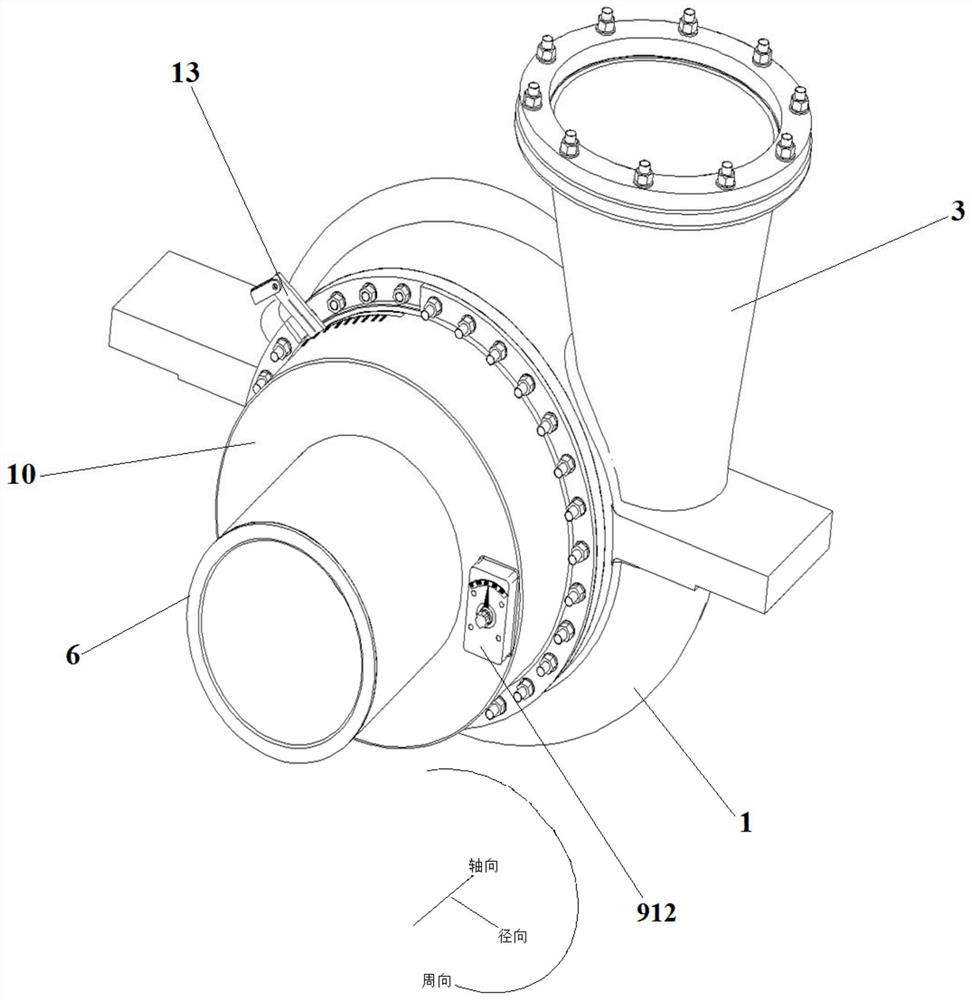

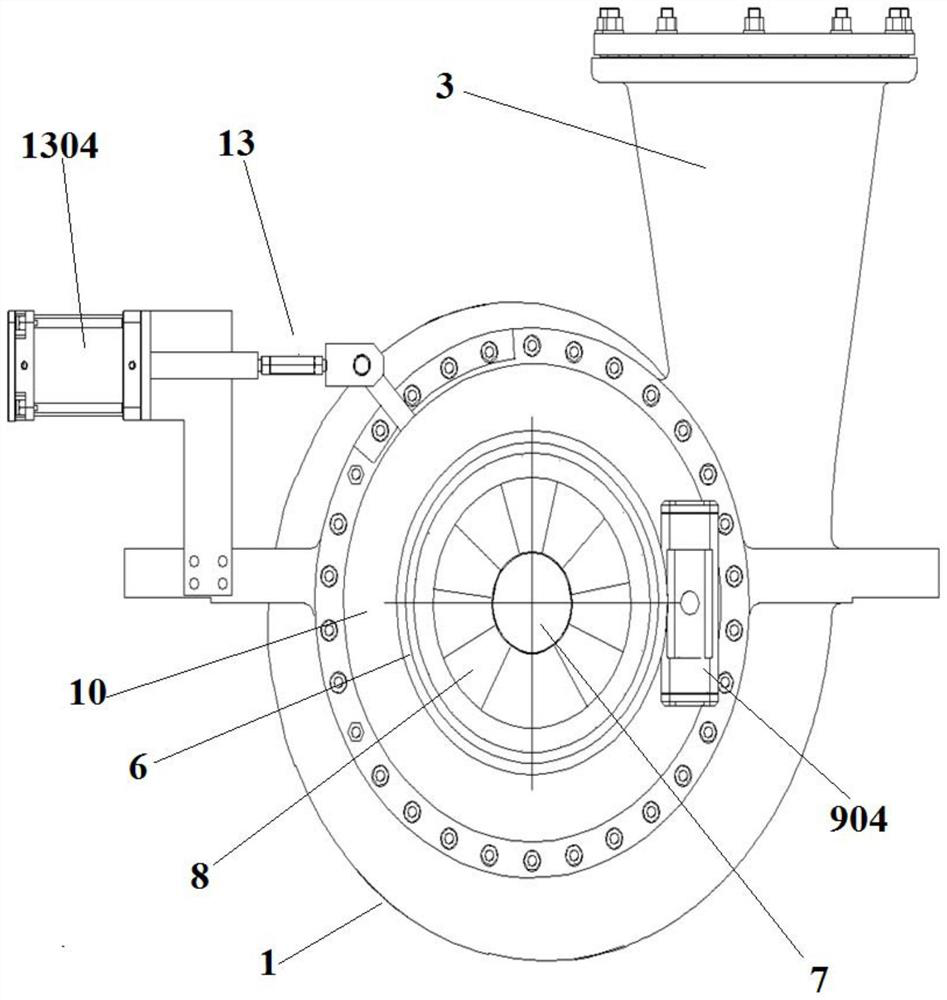

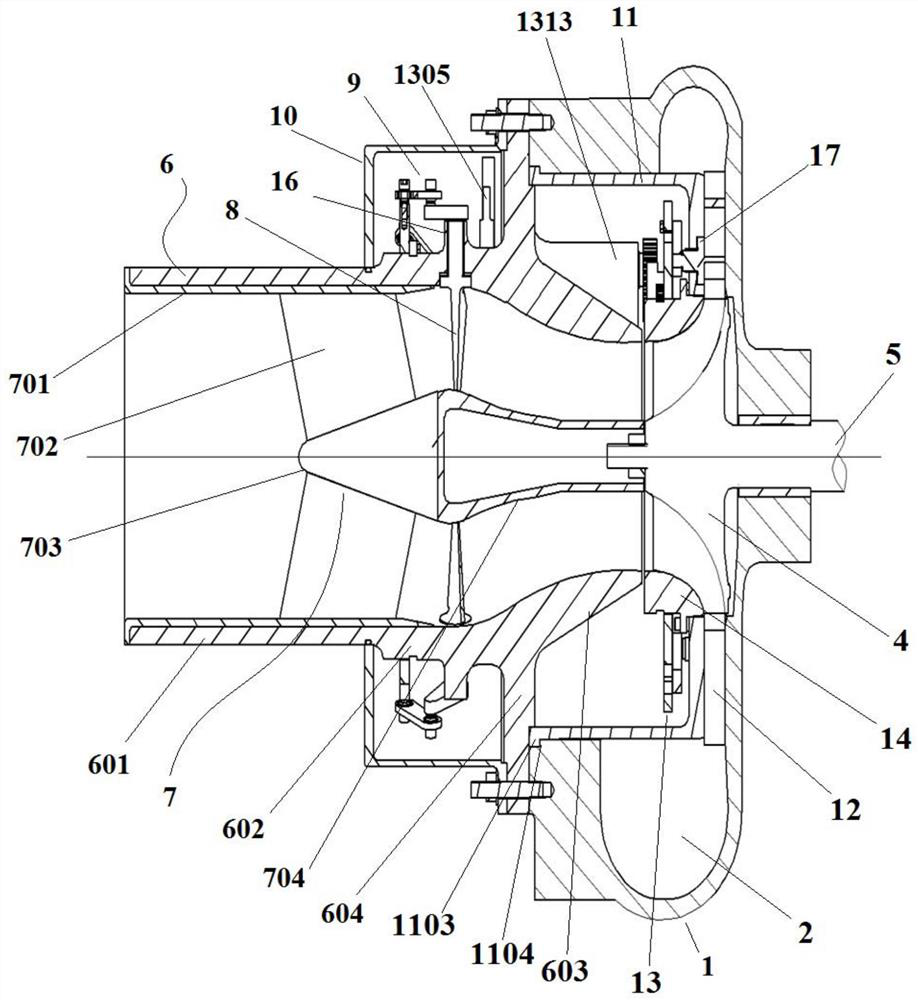

[0058] This embodiment provides a basic level test device for centrifugal compressors that can be adjusted in combination, such as Figure 1 to Figure 11 As shown, it includes a basic-level test volute 1 with one side open and the other side closed. A circle of volute chambers 2 is arranged on the circumferential inner wall of the basic-level test volute 1 . Air cylinder 3; impeller 4 is arranged in basic level test volute 1, the inlet of impeller 4 faces the open side of basic level test volute 1, the outlet of impeller 4 faces volute 2, and impeller 4 extends to the basic level test volute through The impeller outside the closed side of the shell 1 drives the main shaft 5 to rotate;

[0059] An inlet guide vane bracket 6 is installed on the open side of the basic level test volute 1, and an inlet deflector 7 is installed inside the inlet guide vane bracket 6, and multiple inlet guide vanes are installed in the inlet guide vane bracket 6 along the radial direction. The guide...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap