Ultrahigh vacuum pneumatic gate valve

An ultra-high vacuum, plug-in valve technology, used in sliding valves, valve details, valve devices, etc., can solve problems such as large vibration and noise, reduce vibration and noise, reduce production costs, and ensure size and parallelism. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

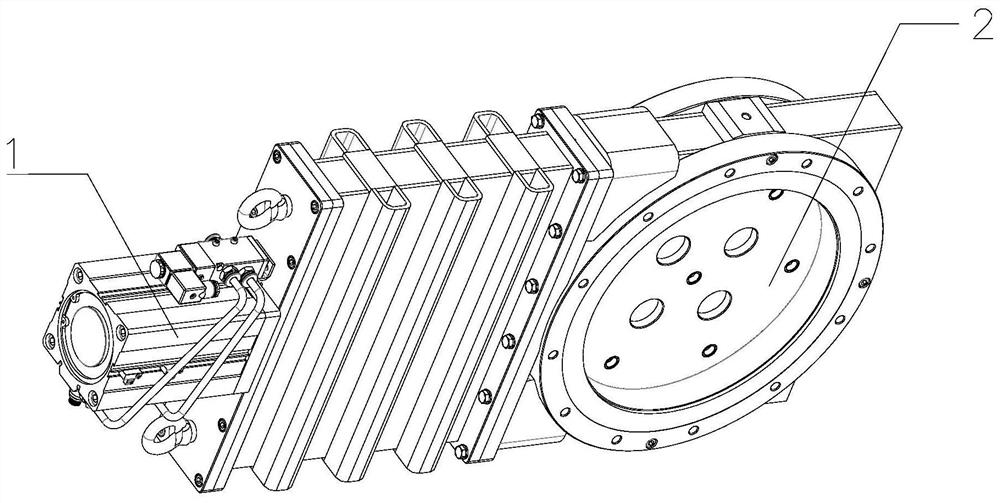

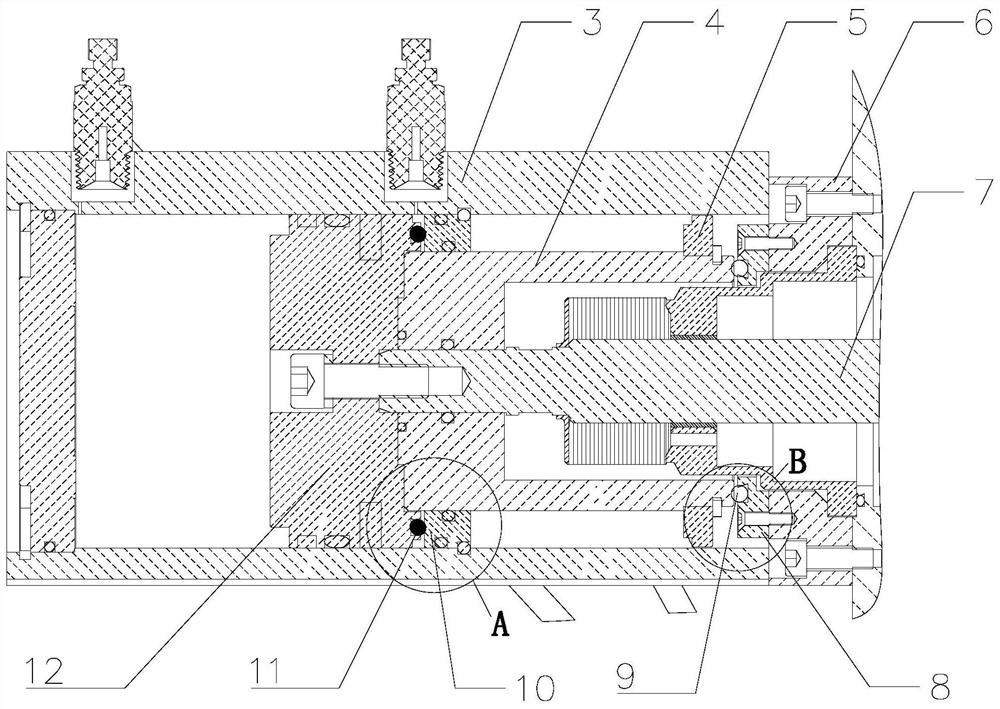

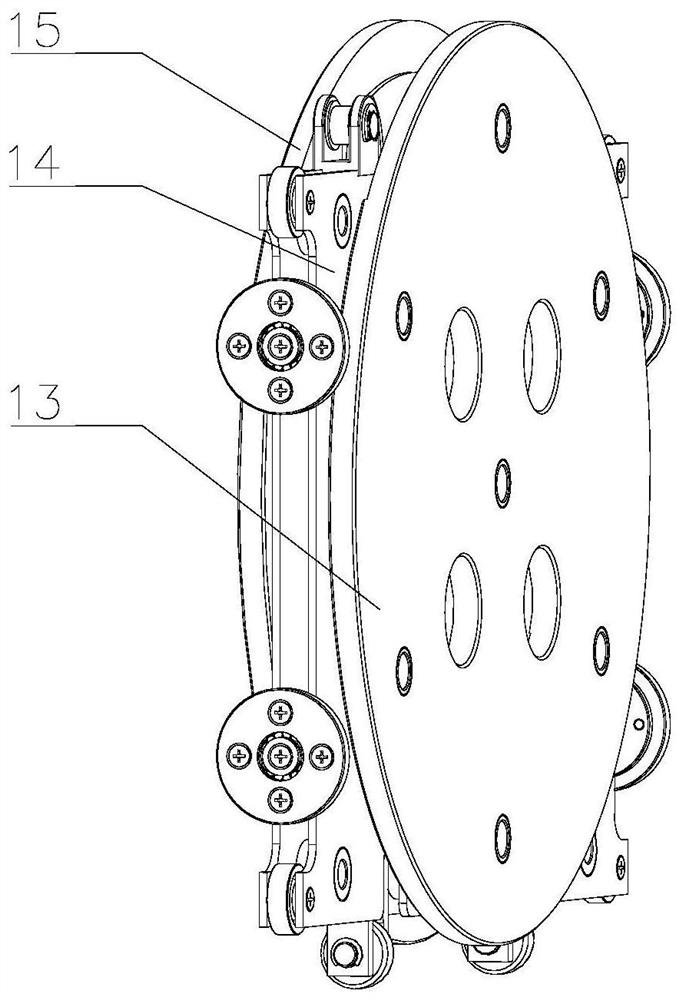

[0047] like Figure 1-7 As shown, an ultra-high vacuum pneumatic flapper valve includes a valve body 2 and a pneumatic propulsion mechanism 1, the pneumatic propulsion mechanism 1 includes a cylinder barrel 3, and a cylinder front end cover 10 and a cylinder piston 12 are installed in the cylinder barrel 3, the cylinder A bellows connecting rod 7 is connected to the piston 12, a guiding mechanism is connected to the bellows connecting rod 7, a cylinder connecting plate 6 is connected to the front end of the cylinder barrel 3, and a front buffer is installed on the side of the cylinder connecting plate 6 close to the guiding mechanism. Mechanism, a rear buffer mechanism is installed on the side of the cylinder piston 12 close to the front end cover 10 of the cylinder; the valve body 2 includes a closing plate 15 and a supporting plate 13, and ball sockets 22 are opened on the opposite surfaces of the closing plate 15 and the supporting plate 13, Two connection plates 14 paralle...

Embodiment 2

[0051] like Figure 1-2 As shown in and 14-15, on the basis of the above-mentioned embodiment 1, this embodiment provides some preferred technical features of the pneumatic propulsion mechanism. That is, the guide mechanism includes a guide cylinder 4 installed on the bellows connecting rod 7 , and a guide ring 5 is installed on the circumferential surface of the guide cylinder 4 . The cylinder guide cylinder 4 and the guide ring 5 are added for more stable guidance during the movement of the cylinder, so the stability and reliability of the vacuum valve during opening and closing can be improved.

[0052] The front buffer mechanism includes a buffer ring 8 installed on the side of the cylinder connecting plate 6, and a front buffer rubber pad 9 is installed on the buffer ring 8, and the cylinder connecting plate 6 and the buffer ring 8 are connected by screws, and the side of the buffer ring 8 has a front installation Groove 21, the front buffer rubber pad 9 is installed in ...

Embodiment 3

[0054] like Figure 3-13 As shown, on the basis of the above-mentioned embodiment 1, this embodiment provides some preferred technical features of the valve core. That is to say, the damping mechanism includes mounting grooves 21 opened on the opposite surfaces of the closing plate 15 and the support plate 13, two connecting plates 14 are provided with waist-shaped holes 141 corresponding to the mounting grooves 21, and the two opposite mounting grooves 21 Buffer tubes 16 passing through the waist-shaped holes 141 are respectively installed inside, and buffer springs 17 are installed between the two opposite buffer tubes 16 . The buffer spring 17 is installed in the guide groove 162, and the buffer cylinder 16 includes an installation body 161 and a guide body 163 formed integrally with each other. The diameter of the installation body 161 is larger than that of the guide body 163, and a plurality of connection holes 1611 are provided on the installation body 161. , the mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com