Simplification method of fuel cell stack fluid simulation model

A fuel cell and fluid simulation technology, applied in fuel cells, fuel cell additives, fuel cell control, etc., can solve problems such as large deviation and pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

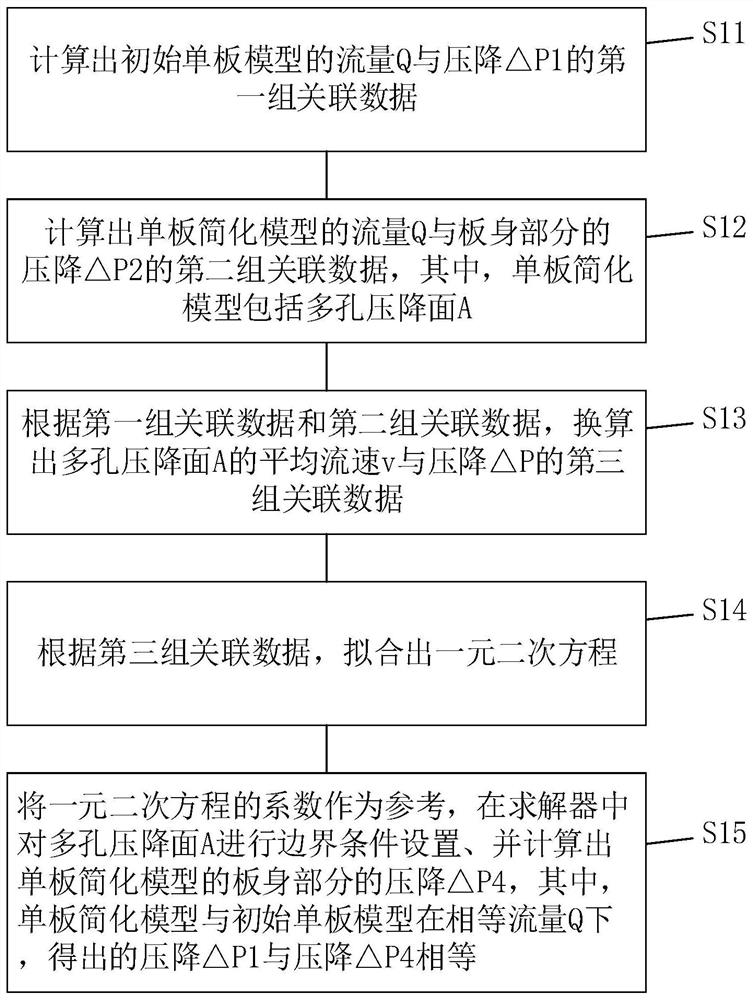

[0050] Please refer to figure 1 , the present embodiment provides a simplified method for a fuel cell stack fluid simulation model, the method includes the following steps:

[0051] S11: Calculate the first set of associated data between the flow rate Q and the pressure drop ΔP1 of the initial single plate model.

[0052] Specifically, by performing flow field simulation on the initial veneer model, at least five sets of calculation results of the corresponding pressure drop △P1 under different flow rates Q are obtained, and at least five sets of associated data between the flow rates Q and the pressure drop △P1 form the first set of associations data.

[0053]S12: Calculate the second set of associated data between the flow rate Q of the simplified model of the single plate and the pressure drop ΔP2 of the plate body, wherein the simplified model of the single plate includes a porous pressure drop surface A.

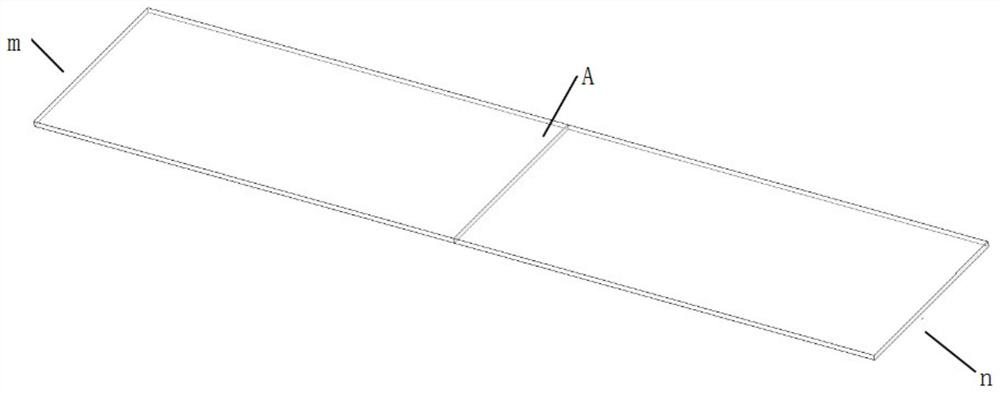

[0054] Specifically, first, see figure 2 , establish a simplif...

no. 2 example

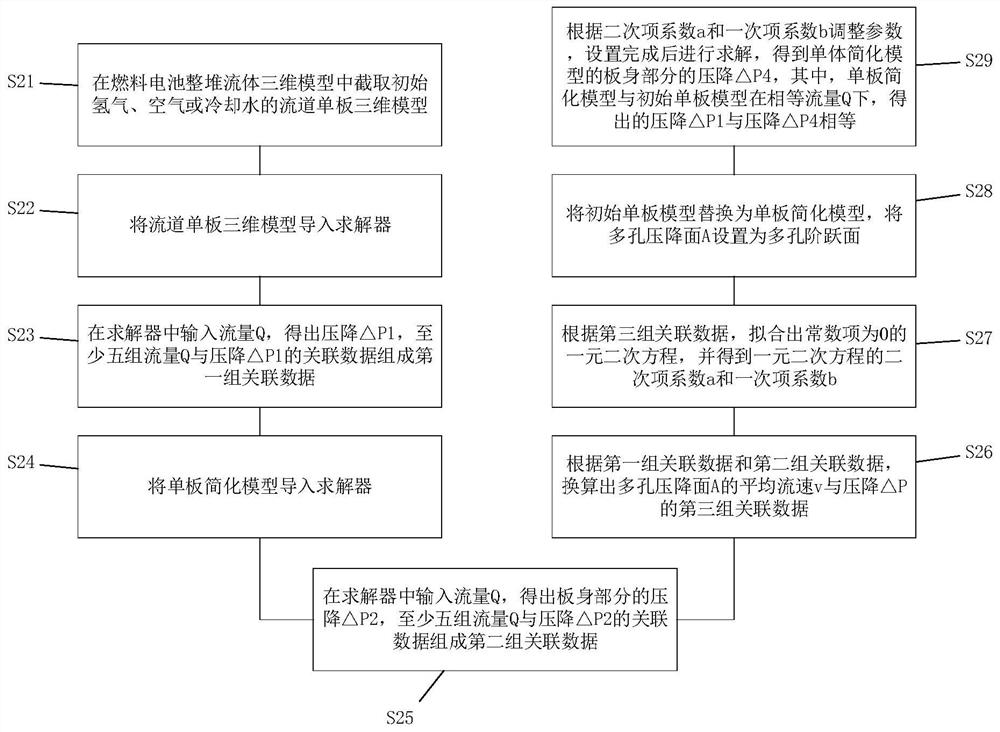

[0072] Please refer to image 3 , the present embodiment provides a simplified method for a fuel cell stack fluid simulation model, the method includes the following steps:

[0073] S21: Intercept the three-dimensional model of the flow channel single plate of initial hydrogen, air or cooling water in the three-dimensional model of the whole stack fluid of the fuel cell.

[0074] S22: importing the three-dimensional model of the runner single plate into the solver.

[0075] Specifically, first, mesh the 3D model of the runner veneer; then, import the 3D model of the runner veneer containing the mesh into the solver; finally, set the boundary conditions for the 3D model of the runner veneer in the solver .

[0076] S23: Input the flow Q into the solver to obtain the pressure drop ΔP1, and at least five sets of associated data of the flow Q and the pressure drop ΔP1 form the first set of associated data.

[0077] Specifically, at least five sets of calculation results of pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com