Auger-type roller, and traction-type peanut picking and harvesting machine using auger-type roller

A traction-type harvester technology, applied in the direction of excavation-type harvesters, applications, harvesters, etc., can solve the problems of low efficiency and poor adaptability of traction-type peanut picking harvesters, etc., to achieve increased work efficiency and design Novel and unique effect with increased working width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

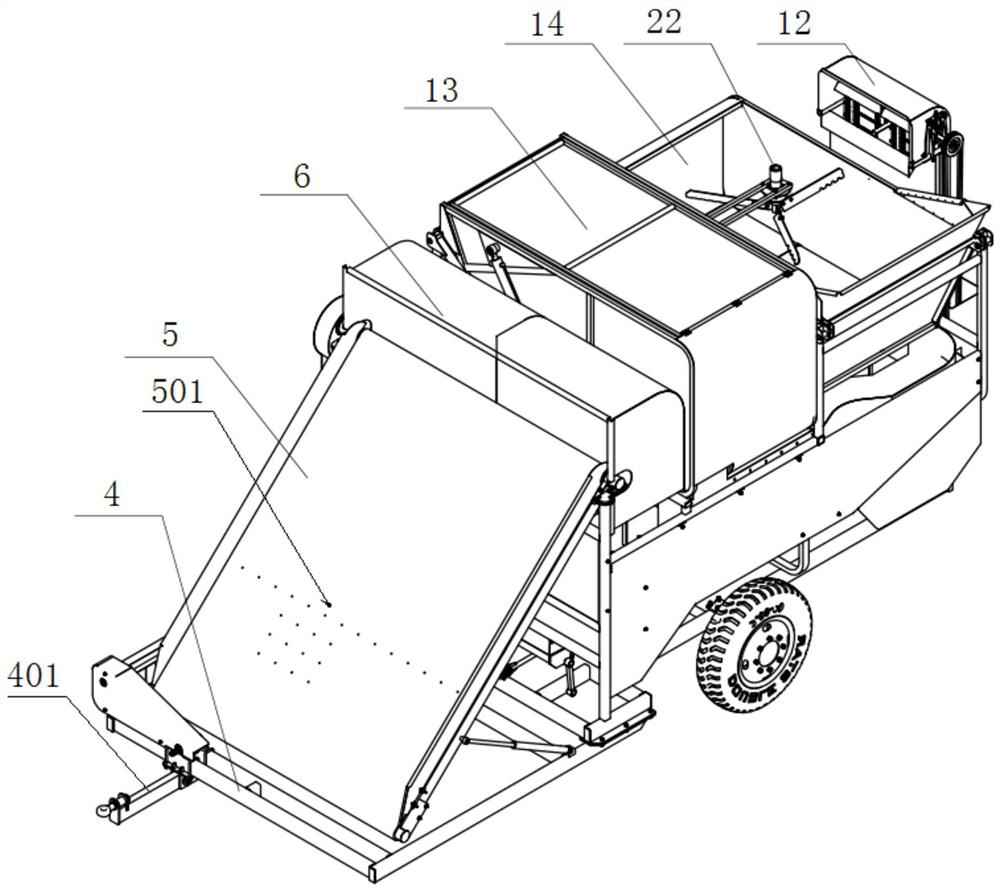

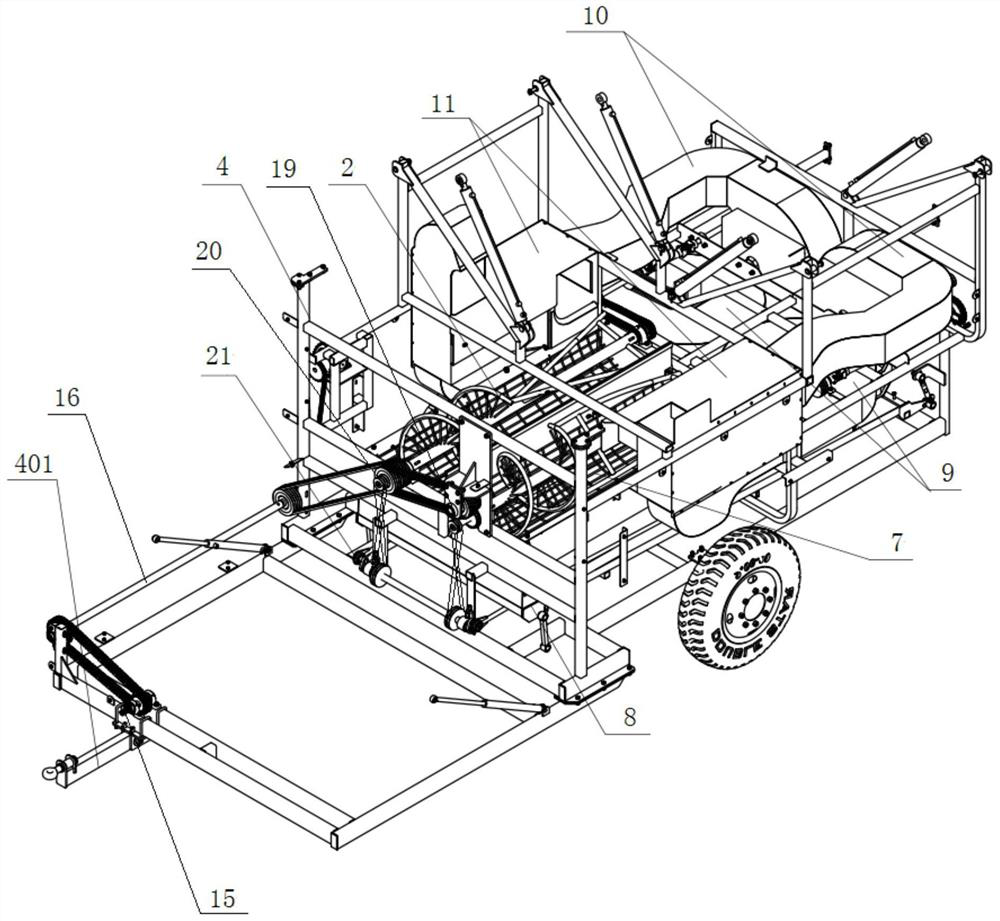

[0051] The traction type peanut picking and harvesting machine using the auger-type roller in this embodiment is a 4HJQ-2500 peanut picking and harvesting machine, which adopts a wide feeder 5, a pair of auger-type rollers, four fans, and a widened The sieve 8, the double-row scoop elevator 12, the enlarged fruit storage box 14, the enlarged seedling bin 13, etc. greatly improve the working efficiency of the whole machine, which can reach twice that of the ordinary traction peanut picking and harvesting machine.

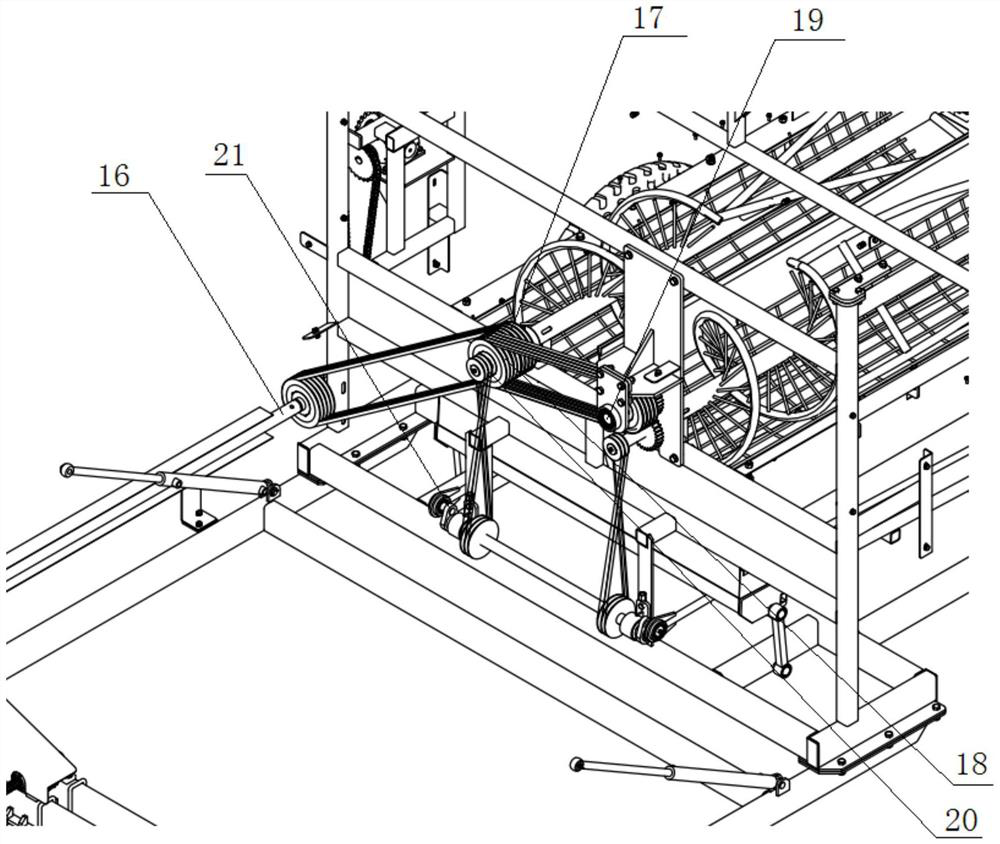

[0052] The traction type peanut picking and harvesting machine using the auger roller includes: the main rack 4, the front end of the main rack 4 is equipped with a wide feeder 5, the picking width is more than 2.5 meters, and the feeder 5 is installed with a belt , The function is to promote the seedlings, and the upper material nail 501 is installed on the plate belt to pick up the seedlings dried on the ground. A hydraulic cylinder for adjusting the lower end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com