Bag feeding device of food packaging bags and working method of bag feeding device

A packaging bag and bagging technology, applied in packaging and other directions, can solve problems such as limited trajectory, complex transition trajectory, and complicated transfer mechanism, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

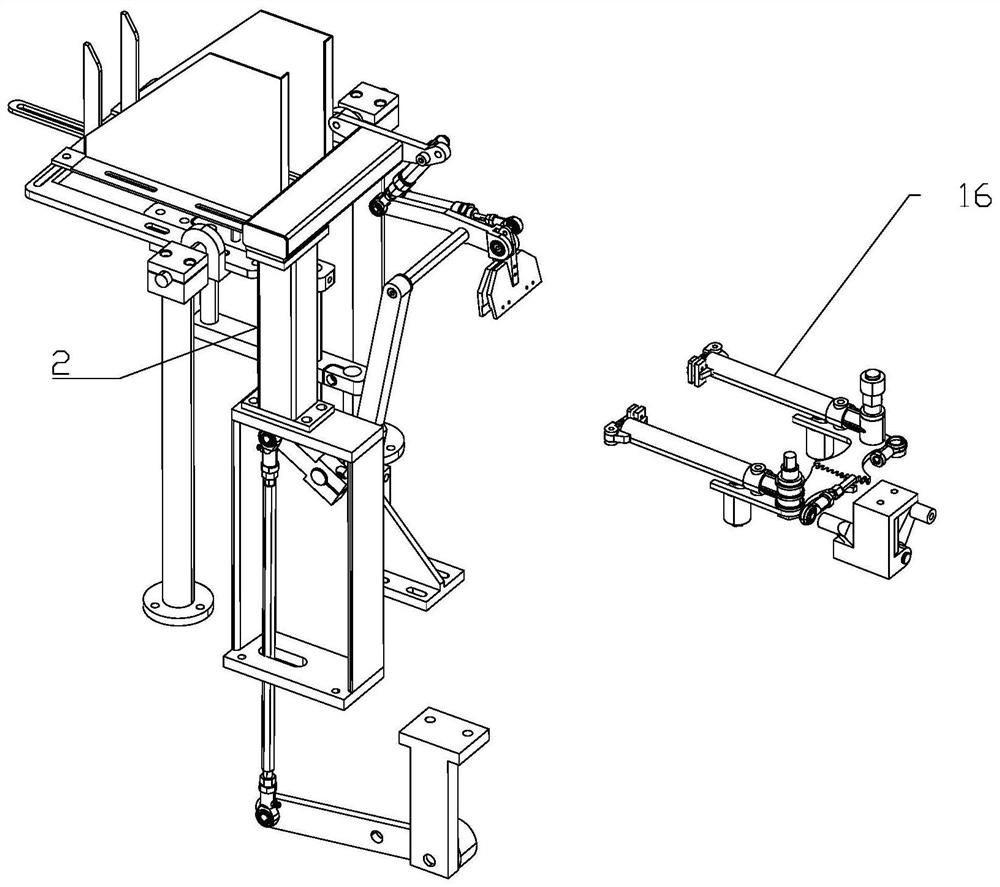

[0019] like figure 1 As shown, a bagging system for food packaging bags includes a bagging device 2 and a plastic bag clamp 16 corresponding to its position. The position of the bagging device corresponds to the side of the plastic bag fixture 16, and the bagging device clamps the packaging bag After separation, the material is loaded to the plastic bag clamp 16 to realize clamping, and the material feeding is completed.

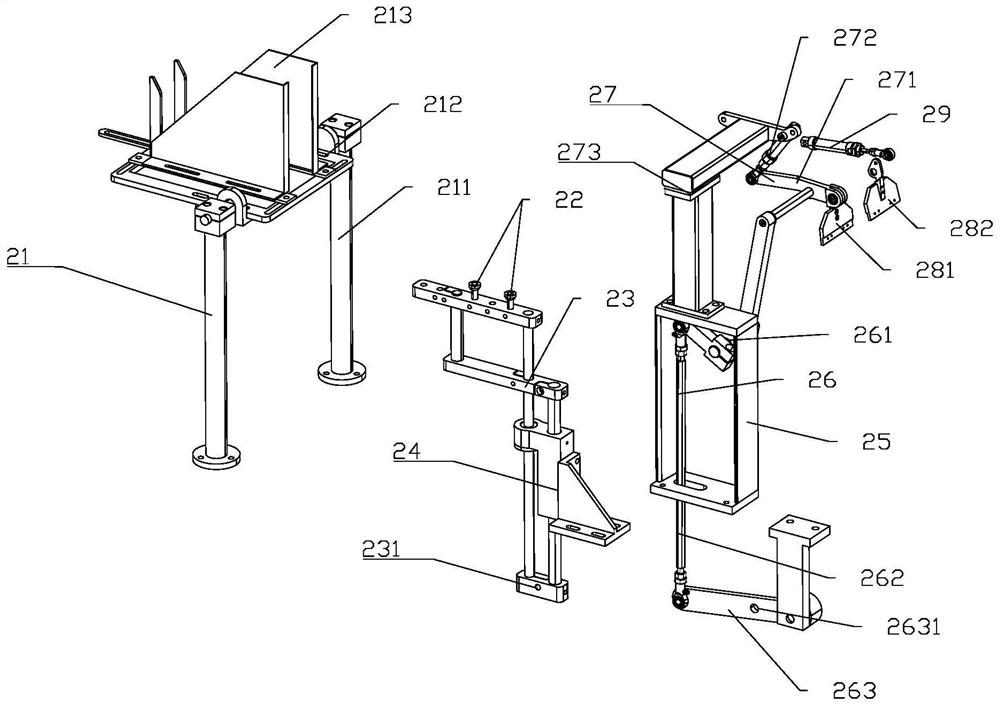

[0020] like figure 2 As shown, the bagging device includes a stacking assembly 21, a suction cup 22, a lifting frame 23, a guide seat 24, a mounting frame 25, a first four-bar mechanism 26, a second four-bar mechanism 27, a fixed splint 281, and a movable splint 282 And clamping cylinder 29; Described lamination assembly 21 is installed on the frame, is provided with stacked packing bag in lamination assembly 21, and described lamination assembly 21 comprises column 211, chassis 212 and side plate 213; Chassis 212 installs Above the column 211, side plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com